Device Features

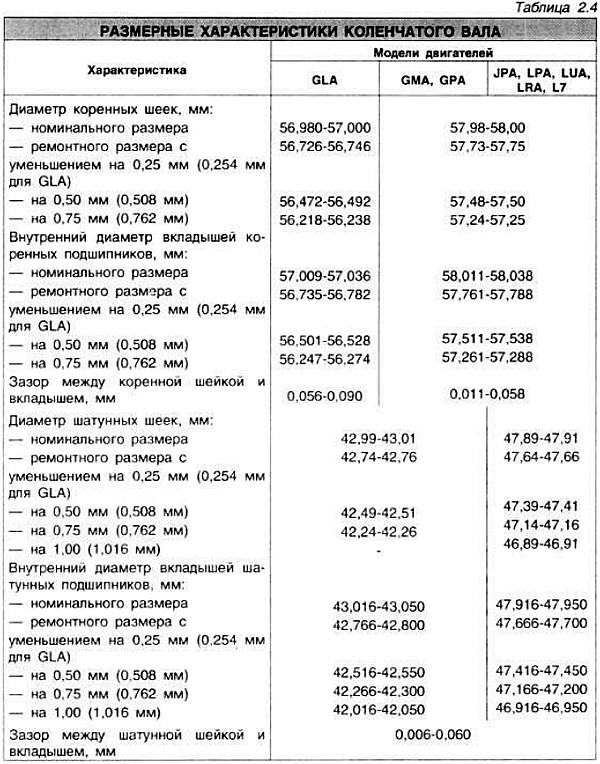

The crankshaft is cast from spheroidal graphite iron, dynamically balanced. mounted on five pillars (GLA engine on three). Axial movement of the crankshaft is limited by thrust half rings with a thickness of 2.301-2.351 mm of nominal size, 2.491-2.541 mm of repair size (for the GLA engine - 2.80-2.85 mm and 2.99-3.04 mm, respectively). The value of the axial clearance of the crankshaft is 0.079-0.279 mm for the GLA engine. 0.09-0.30 mm for engines of other models. The width of the main bearing shells of the GLA engine is 22.04-22.10 mm.

Flywheel

The flywheel is attached to the crankshaft flange with six bolts (five for the GLA engine). The flywheel with crankshaft and clutch assembly is statically and dynamically balanced. The gear rim is installed on the flywheel with an interference fit. To do this, before installation, it is heated to a temperature of 260-280°C.

Replacing the front crankshaft oil seal (all engine models except GLA)

Disconnect the cable from the negative battery terminal and loosen the crankshaft sprocket bolt. Loosen the alternator and remove the accessory drive belt. Remove pulley from crankshaft. Remove the front protective cover of the toothed belt and, turning the crankshaft, align the marks of the toothed pulleys, as indicated in the section «Camshaft». Loosen the two bolts securing the toothed belt tensioner, press the tensioner to the left and tighten the bolts again. Remove toothed belt.

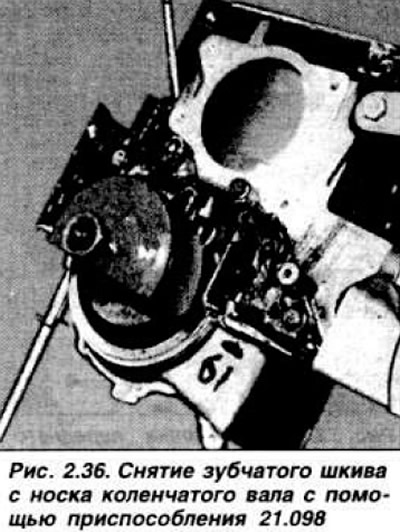

With tool 21.098 (pic. 2.36) remove the toothed pulley and thrust washer. Remove front crankshaft oil seal from oil pump housing (pic. 2.37).

Lightly coat the sealing lips of the new oil seal with engine oil and install with special tool 21.093. Install the thrust washer with the convex side facing out. Install the toothed pulley using the accessory drive belt pulley, tightening its fastening bolt to a torque of 10.0-11.5 kgf·m. Check the correct installation of the toothed pulleys, install the toothed belt, protective cover and tighten the bolts of its fastening with a torque of 0.7-0.9 kgf·m. Put on and tension the auxiliary drive belt; connect the battery.

Replacement of a forward epiploon of a cranked shaft of the engine of the GLA model

The engine may remain on the vehicle for this operation, however. due to difficult access to the gland. special fixtures are required.

Disconnect the wire from the negative battery terminal. Remove the alternator mounting bracket and adjusting bar. Remove the accessory drive belt. Raise the vehicle and, working from below, unscrew the bolt securing the accessory drive pulley and remove the pulley. With tool 21.096 (pic. 2.38) remove the crankshaft seal.

Lightly coat the lips of the new oil seal and the crankshaft nose with engine oil. Install the oil seal and push it into the socket with your hand. Install drift 21.046 (pic. 2.39) on the stuffing box, then install the pulley and gradually tighten the bolt of its fastening until the stuffing box is seated.

Remove the pulley and mandrel, then install the pulley and tighten its fastening bolt to a torque of 5.4-5.9 kgf·m. Lower the car. put on and tension the accessory drive belt. The total deflection of the belt in both directions must be 13 mm (see section «Cooling system»). Check the oil level in the crankcase and connect the battery.

Visitor comments