Device Features

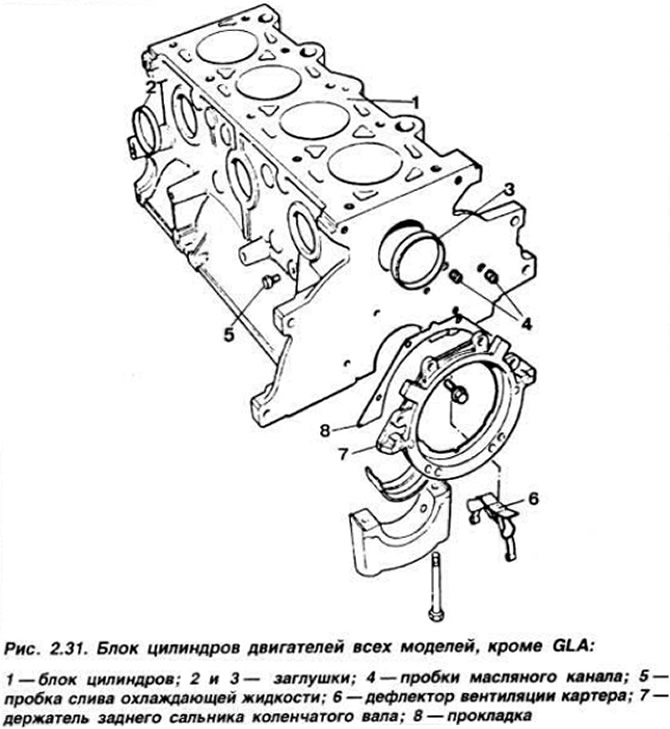

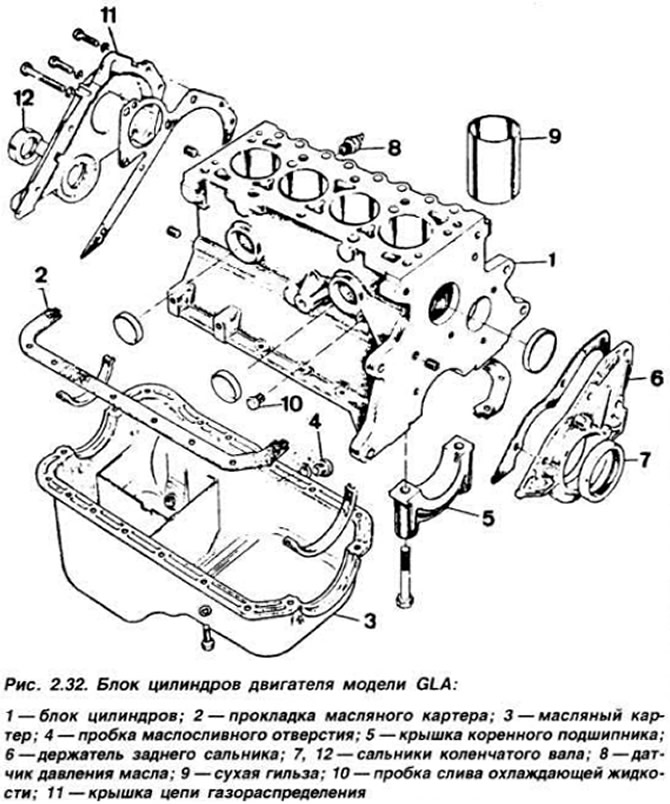

The engine cylinder block is cast iron and is integral with the cylinders (pic. 2.31), except for the GLA engine, which has thin-walled dry liners (fig.2.32).

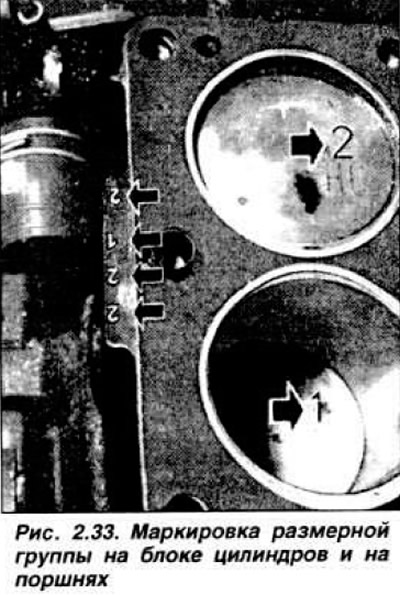

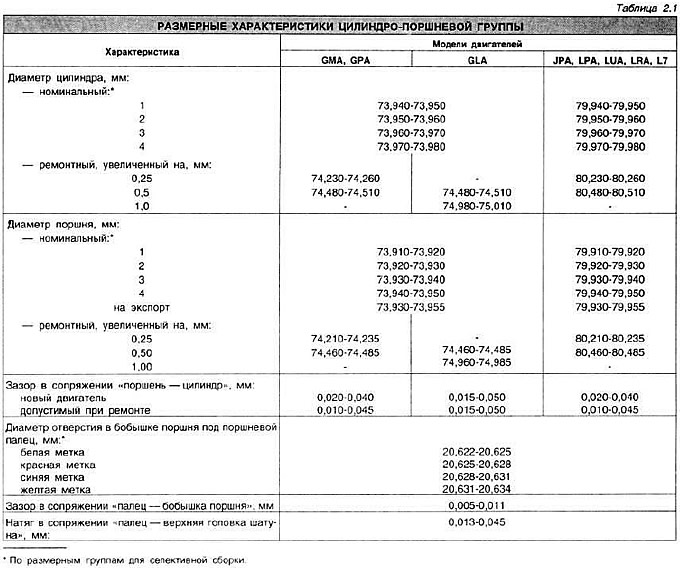

To ensure the required working clearance in mating «piston - cylinder» the nominal size of the cylinder is divided into four size groups through 0.01 mm. Dimensional groups are distinguished by the markings applied to the tide of the cylinder block (pic. 2.33. see table. 2.1).

Diameter of beds for main bearing shells of all models, except GLA: nominal 62.287-62.300 mm; repair with an increase of 0.400 - 62.687-62.700; GLA models: nominal - 60.623-60.636 mm; repair - 61.003-61.016 mm. Width of the middle bearing of the crankshaft; 28.825-28.875 mm. The diameter of the holes for the camshaft bushings of the GLA engine: nominal - 42.888-42.918 mm; repair 43.396-43.420 mm.

Check and repair

After flushing, blowing and drying the cylinder block with compressed air, make sure that there are no cracks. If there are cracks, replace the cylinder block. Check the split plane of the cylinder block with the head using a ruler and a set of feeler gauges. The flatness tolerance is 0.1 mm. Using an inside gauge, measure the ovality and taper of the cylinders. If the wear is more than 0.15 mm, bore and hone the cylinders so that when installing the selected repair piston, the gap between it and the cylinder is 0.010-0.045 mm.

Visitor comments