Device Features

The piston is die-cast aluminum alloy. The bottom of the piston is flat, with recesses for the valve plates (except GLA). Just like cylinders, pistons of nominal size are divided into four groups with an interval of 0.01 mm. These groups are distinguished by the markings applied to the piston crown. When repairing the engine, it is necessary to measure the cylinders and pistons, and if the gap exceeds 0.15 mm. match the pistons to the cylinders, providing the required clearance in mating. According to the diameter of the hole in the bosses for the piston pin, the pistons are divided into four groups through 0.003 mm. The piston pins are steel, polished, pressed into the upper head of the connecting rods and rotate freely in the piston bosses. Piston pin length for GMA, GPA and GLA engines: 63.00-63.80 mm; for other engines; 66.20-67.00 mm The diameter and marking of the piston pins are the same. as well as the holes in the piston bosses.

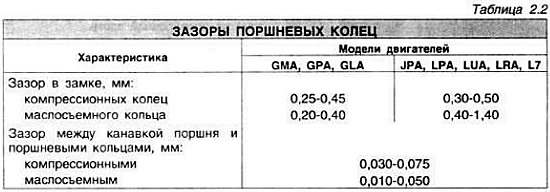

Three rings are installed on each piston - two compression and one oil scraper. When installing the oil scraper ring, spread the locks of its elements through 120°. the gap in the lock of the lower oil scraper ring should be at an angle of 90°. and the upper compression - at an angle of 150°with respect to the lock of the oil scraper ring.

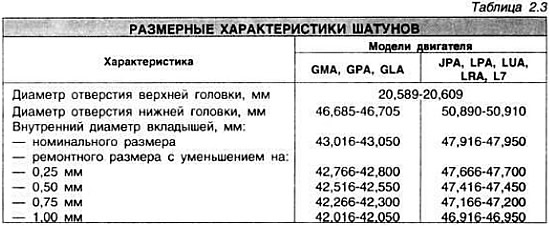

Connecting rods - steel, forged, I-section. A bushing is pressed into the upper head of the connecting rod, and thin-walled liners are installed into the lower head during assembly.

Disassembly and assembly of the connecting rod and piston group

The piston pin is removed using a press and mandrel. Before assembly, check the bending and twisting of the connecting rod on the test plate.

NOTE: When assembling, make sure that the arrow on the piston points in the same direction as the oil hole and mark «F» on the connecting rod (pic. 2.34).

Install the piston on the tool (pic. 2.35), arrow away from fixture.

Lubricate both piston pin bores with engine oil and insert the pin guide into the bore of the tool. Insert the piston pin into the piston boss to its inner end. Install a template with a label in the fixture «Essex». Heat the upper head of the connecting rod to a temperature of 260-400°C. Control the temperature with a thermochromic pencil. Quickly insert the connecting rod into the piston and press it against the shoulder of the guide mandrel. Press piston pin in as far as it will go. Allow the assembled unit to cool before removing it from the fixture. It is impossible to change the position of the piston pin after the connecting rod has cooled due to a significant interference.

Visitor comments