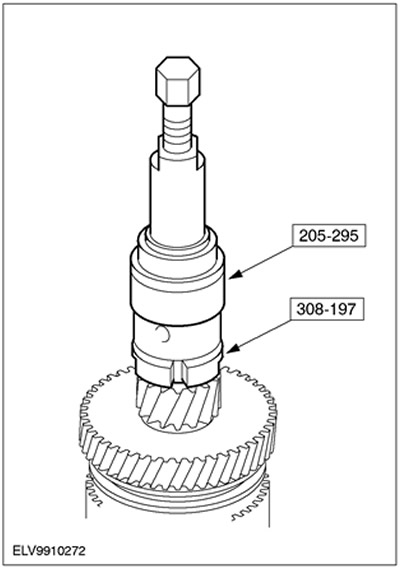

Special tool

| Bearing puller (main instrument) 205-295 (15-050A) |

| Collet for 15-050 A/205-295 308-197 (16-062) |

| Bearing/Gear Puller 205-310 (15-091) |

General Equipment: Press.

| Name | Specification |

| transmission fluid | WSD-M2C200-C |

Disassembly

1.

CAUTION: The synchronizer inner ring and taper ring must be handled with great care.

General notes

- General view of the secondary shaft. For more information, please refer to the chapter Description and function available in this section.

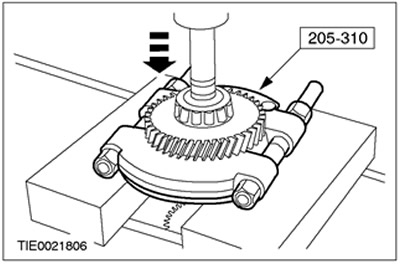

2. Remove the gearbox housing roller bearing together with the reverse gear using the special tool.

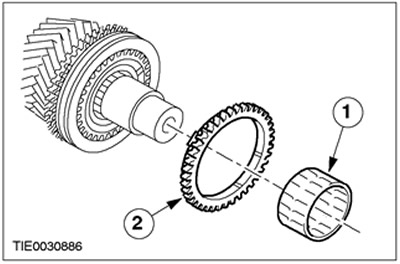

3. Remove the reverse gear synchronizer ring.

- 1. Remove the needle roller bearing.

- 2. Remove the synchronizer ring.

4.

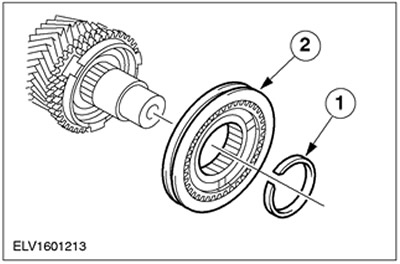

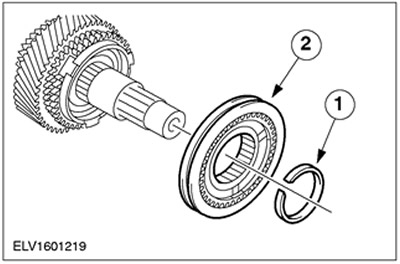

NOTE: Discard spring ring as it is no longer needed.

Remove the 5th/reverse synchro.

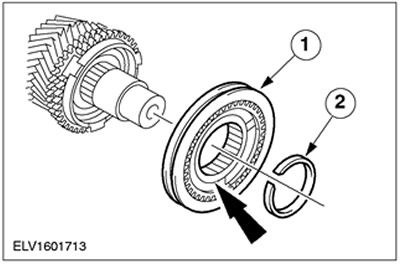

- 1. Remove the retaining ring.

- 2. Remove the synchronizer assembly.

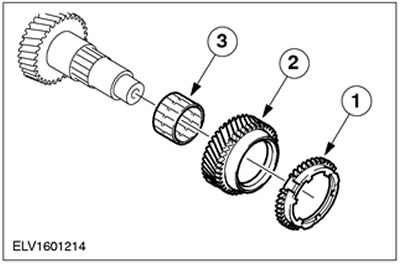

5. Remove the 5th gear along with the synchronizer ring and needle roller bearing.

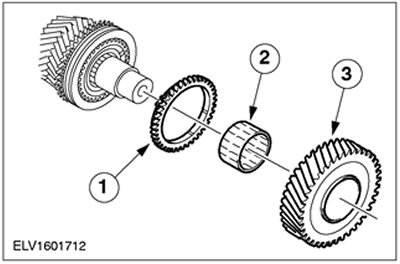

- 1. Synchronizer ring

- 2. 5th gear

- 3. Needle roller bearing

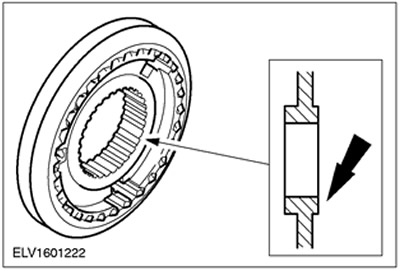

6. Remove the tapered roller bearing from the clutch side.

7.

CAUTION: The output shaft and output gear form a common pair and must only be replaced in pairs.

NOTE: Discard retaining ring as it is no longer needed.

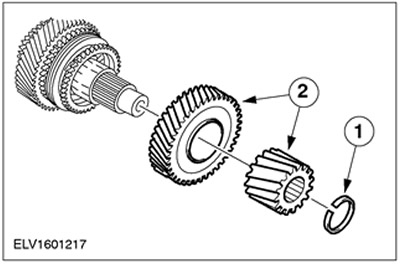

Remove the output gear and 1st gear.

- 1. Remove the retaining ring.

- 2. Remove the output gear along with the 1st gear.

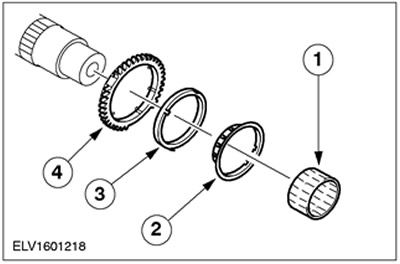

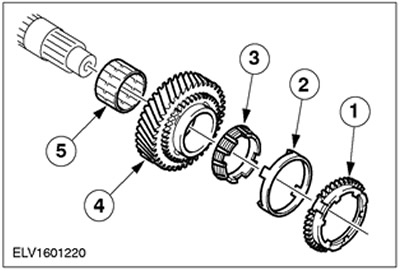

8. Disconnect the double synchronizer together with the needle roller bearing.

- 1. Needle roller bearing

- 2. Synchronizer inner ring

- 3. Tapered synchronizer ring

- 4. Synchronizer outer ring

9.

NOTE: Discard spring ring as it is no longer needed.

Connect the 1st/2nd gear synchronizer.

- 1. Retaining ring

- 2. Synchronizer assembly

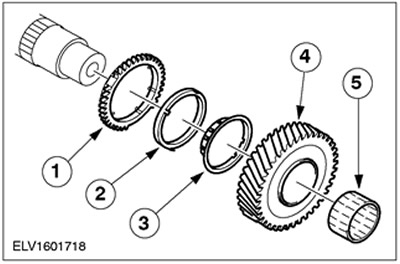

10. Remove the double synchronizer together with the 2nd gear.

- 1. Synchronizer outer ring

- 2. Tapered synchronizer ring

- 3. Synchronizer inner ring

- 4. Gear 2nd gear

- 5. Needle roller bearing

11.

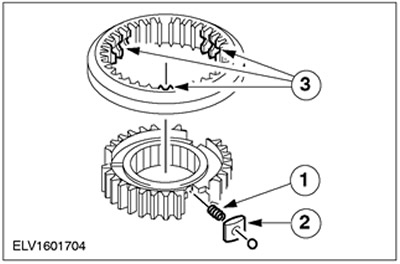

CAUTION: Carefully remove the synchronizer sleeve from the synchronizer hub. The locking balls are under spring force.

NOTE: Mark the position of the synchronizer clutch.

Disassemble the synchronizer assembly.

- 1. Remove the synchronizer clutch.

- 2. Synchronizer hub

- 3. Compression spring

- 4. Rusk

- 5. Locking ball

Assembly

1.

NOTE: Do not apply oil to reusable tapered roller bearings. Install new tapered roller bearings (raw).

Carefully clean and inspect all components and coat them with transmission fluid before reassembly.

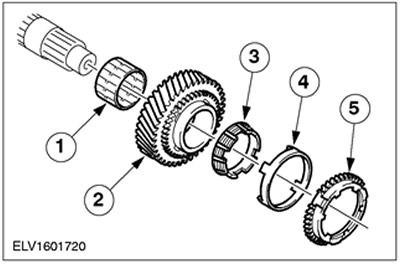

2. Install the 2nd gear with double synchronizer and needle roller bearing.

- 1. Needle roller bearing

- 2. Gear 2nd gear

- 3. Synchronizer inner ring

- 4. Tapered synchronizer ring

- 5. Synchronizer outer ring

3.

NOTE: Pay attention to the markings.

Assemble the 1st/2nd gear synchronizer.

- 1. Insert compression springs.

- 2. Insert the crackers together with the locking balls, overcoming the force of the spring.

- 3. Set the gear selection ring to the correct position and move it forward.

4.

NOTE: Connect the synchronizer hub with the small protrusion and the annular groove facing outwards (towards 1st gear).

Installation position of the synchronizer 1st / 2nd gear

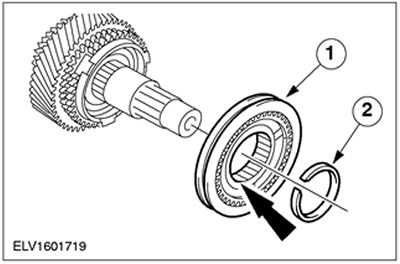

5. Install the 1st/2nd gear synchronizer.

- 1. Synchronizer assembly

- 2. Install a new circlip.

6. Install the 1st gear with dual synchronizer

- 1. Synchronizer outer ring

- 2. Tapered synchronizer ring

- 3. Synchronizer inner ring

- 4. 1st gear

- 5. Needle roller bearing

7.

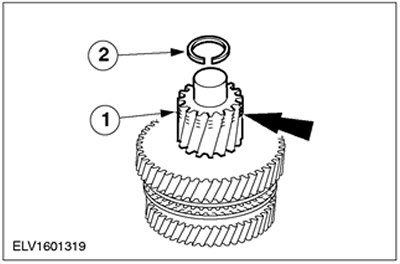

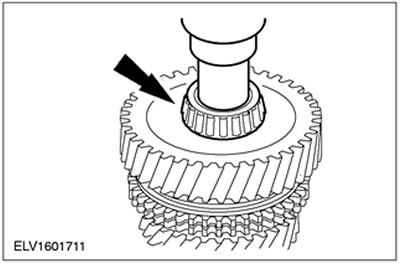

CAUTION: The output gear can only be splined in one position.

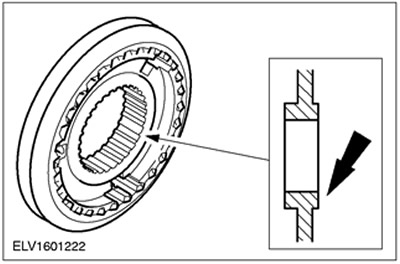

Press on the output gear.

- Install the output gear with the markings facing up.

- 1. Press on the output gear using a suitable piece of pipe and a press.

- 2. Install a new retaining ring.

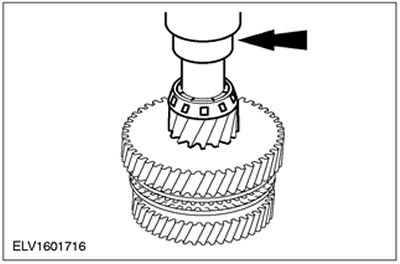

8. Press on the tapered roller bearing from the clutch side.

- Press on the tapered roller bearing using a suitable piece of pipe and a press.

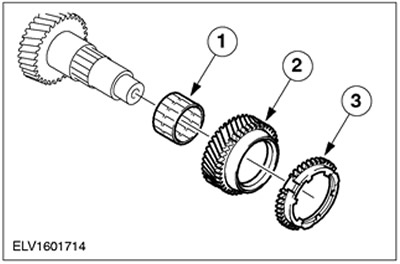

9. Install the 5th gear with synchronizer ring and needle roller bearing.

- 1. Needle roller bearing

- 2. 5th gear

- 3. Synchronizer ring

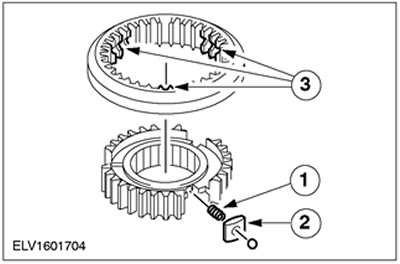

10.

NOTE: Pay attention to the markings.

Assemble the 5th/reverse synchro.

- 1. Insert compression springs.

- 2. Insert the crackers together with the locking balls, overcoming the force of the spring.

- 3. Set the gear selection ring to the correct position and move it forward.

11.

NOTE: Connect the synchronizer hub with the small protrusion and the annular groove facing outwards (towards reverse gear).

Installation position of 5th gear/reverse synchro assembly

12. Install the 5th/reverse synchro assembly.

- 1. Synchronizer assembly

- 2. Install a new circlip.

13. Install reverse gear.

- 1. Synchronizer ring

- 2. Needle roller bearing

- 3. Reverse Gear

14. Press on the tapered roller bearing from the transmission side.

- Press on the tapered roller bearing using a suitable piece of pipe and a press.

Visitor comments