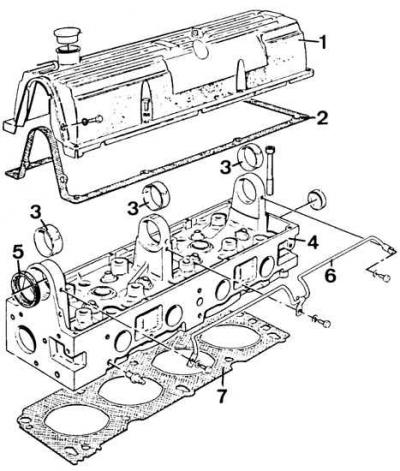

Cylinder head assembly

1 - cylinder head cover, 2 - cover gasket, 3 - camshaft bearing bushings, 4 - cylinder head, 5 - camshaft sealing ring, 6 - oil supply line to the camshaft bearings, 7 - cylinder head gasket

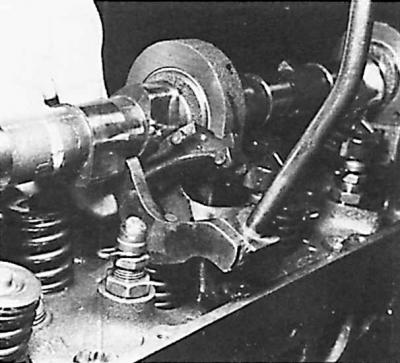

Longitudinal fixation of the camshaft

1 - mounting plate, 2 - camshaft

Disassembly

1. Position the cylinder head at the front and rear on two pieces of wood.

2. Remove intake manifold with carburetor and coolant outlet pipe.

3. Unscrew the thermal shroud and then the exhaust manifold.

4. Unscrew the studs securing both collectors.

5. Unscrew the coolant temperature sensor.

6. Remove the oil supply pipes to the camshaft bearings.

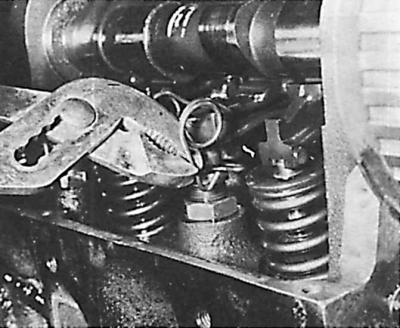

7. Take off (fixture 21.005 A) in order, the valve lever springs, as well as the valve levers.

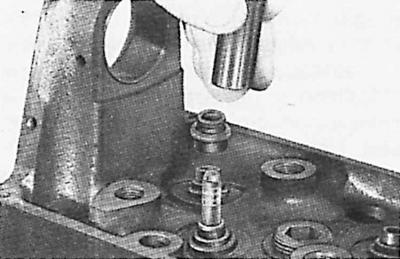

8. Compress the valve springs (fixture 21.005 A), remove the wedges of the crackers securing the upper thrust plate of the spring. Remove the top poppet and valve spring, being careful not to damage the valve necks.

9. Remove the pulley from the camshaft by holding the camshaft with a flat wrench in the grooves behind the sixth cam. Remove the thrust washer of the camshaft pulley, as well as its sealing ring.

10. Unscrew the two screws securing the thrust flange at the rear of the camshaft and carefully pull the camshaft back. Unscrew the bolts that form the stop for the valve lever, ending with ball ends. If they are to be used later, they should be marked in such a way that they will be installed in the same places during assembly and can interact with the same valve levers.

11. Unscrew toothed belt tensioner (fixture 21.012) and remove the spacer.

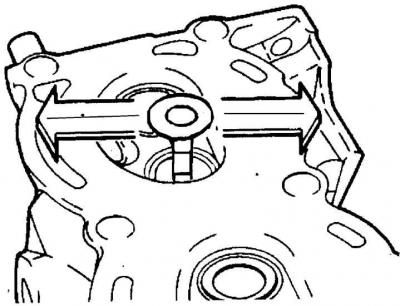

Checking the valve guides

Worn valve guides do not align the valves in their seats, resulting in a significant increase in fuel and oil consumption.

1. Insert the valve into the guide sleeve and move the valve laterally to check the clearance.

2. If the gap exceeds the allowable limits, it is necessary to machine the guide sleeve using an appropriate reamer to the next enlarged size. The processing of the guide sleeve must be started from the side of the combustion chamber.

3. If the guide bushings have been machined, it is necessary to install valves with oversized stems.

4. Processing of valve seats in the cylinder head.

5. Valve seats with signs of wear or burning must be processed with the obligatory preservation of angles and chamfers. Otherwise, it is necessary to replace the cylinder head. After any processing of the valve seats, it is necessary to grind the valves.

Lapping

1. The valves should be lapped using only fine-grained polishing paste.

2. Lubricate the surface of the valve seat with a small amount of paste and install the valve in the appropriate seat. Firmly press the rubber suction cup against the valve plate and rotate the valve in one direction or the other.

3. After the end of the lapping process, thoroughly clean all parts from dirt and tar and check the valve seat and disc. A solid opaque ring should be visible on both parts, which indicates the width of the valve chamfer.

Assembly

1. Screw in the manifold mounting studs, and then the coolant temperature sensor.

2. Lubricate with SAE 80/90 hypoid gear oil the journals, cams and thrust surfaces of the camshaft, the inner surfaces of the bearing rings, the ball ends of the valve lever stop bolts, and the surfaces of the valve lever that interact with the camshaft cams.

3. Insert the camshaft at the rear of the cylinder head until its journals are seated in the bearing rings, being careful not to damage the sliding surfaces.

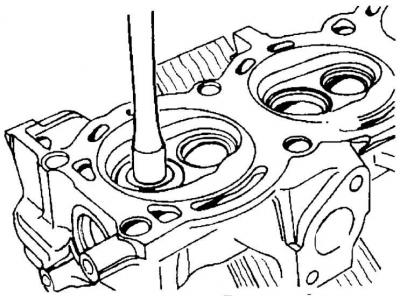

4. Screw in the bolts that support the valve lever and the nuts that protect them from unscrewing. Lubricate the valve stems and valve guides with SAE 80/90 grade hypoid oil. Insert the valve and cover with adhesive tape the place where the crackers are installed.

5. Lubricate the oil seals with engine oil, insert them (attachment 21.007) and remove the adhesive tape from the valve stems.

6. Insert valve springs and upper plates in order. Compress the springs and insert crackers.

7. Install the valve lever.

8. Lubricate with oil and install a new camshaft front bearing O-ring.

9. Insert thrust washer and gear (reinforced side out) to the distributor.

10. Install the springs holding the valve lever and adjust the valve clearance.

11. Install spacer, toothed belt guard and tensioner.

12. Screw the oil supply pipes to the camshaft bearings, the cylinder head coolant return chamber, and the thermostat (new gasket).

13. Lay a 5 mm sealing cord on the intake manifold gasket (A 70 SX 19554-BA), install new exhaust manifold gaskets and screw both manifolds.

14. Screw on the exhaust manifold heat shield.

Attention! When installing previously used valves in a new cylinder head, proceed as follows:

- grind the valves and their sockets;

- carefully clean the paste remaining after grinding, lubricate the valve stems with oil and then proceed as described above.

Visitor comments