Withdrawal

Disconnect ground wire (-) battery.

Caution: Disconnecting the battery will erase the contents of the electronic memories, such as engine trouble codes or radio codes. Before switching off, also read the instructions in chapter "Removing and installing the battery".

Put the wheels of the car in a straight line position.

Loosen and remove the radiator shroud (not for DOHC engine).

Raise the car on the goats.

If equipped, remove the lower engine compartment cover.

Drain engine oil, see section "Maintenance".

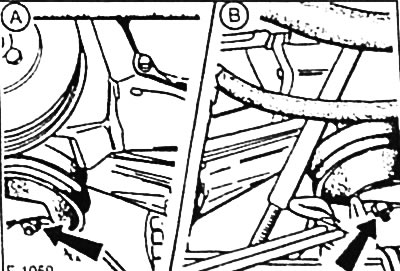

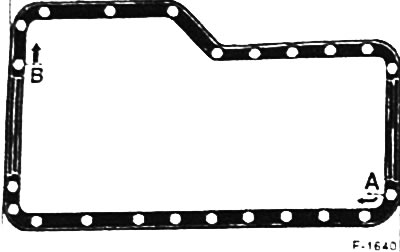

Remove nuts -arrows- for both engine mounts (A: right side of engine, B: left side of engine).

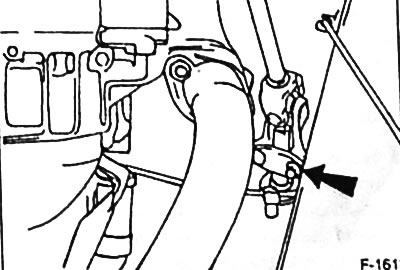

Using a scriber, mark the position of the link plate in relation to the steering shaft.

Unscrew bolt -arrow- for steering shaft coupling and swivel plate to one side.

Petrol engine: remove starter, see p. 167.

Attach a lifting device to the lifting eyes of the engine and slightly raise the engine with a crane (hoist).

Remove all bolts and nuts securing the oil pan and separate it from the crankcase. Press firmly seated oil pan from the side with a screwdriver.

Attention: Do not damage the sealing surfaces of the crankcase and sump.

Detach the brake pipes on the left and right of the connecting beam.

Using a garage jack, support the connecting beam by first placing a wooden block between the beam and the jack.

Unscrew the 4 bolts -A- securing the connecting beam and carefully lower it on the jack.

Attention: Lower the connecting beam so far that the oil pan can be pulled out.

Pull out the oil pan.

Installation

Carefully clean the sealing surfaces of the oil pan and crankcase to remove any remaining sealing material. Straighten contact surfaces of oil pan if they were bent during removal.

ONS engine and 2.8L engine

Apply FORD A70SX-19554-BA sealant to the joint at the end cover of the crankcase.

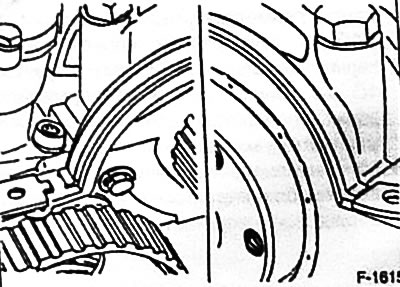

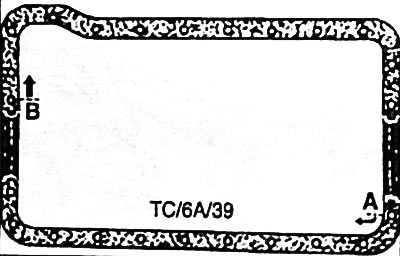

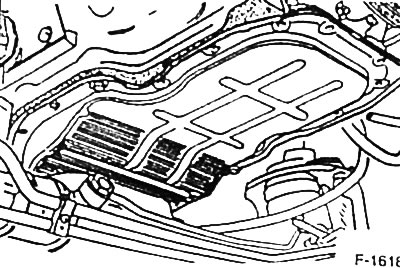

Glue the new sealing kit to the crankcase with FORD A70SX-19554-BA sealant, while ensuring the correct position of the oil pan sealing gasket, see figure.

Attach the oil pan, screw in all the mounting bolts by hand and then plug them in 2 steps:

- Reception 1: starting from position -A-. tighten all bolts by hand to 1-2 Nm (for an engine with a working volume of 2.8 l - a torque of 5 Nm).

- Reception 2: starting from position -B-, tighten all bolts to 8 Nm (for an engine with a displacement of 2.8 liters - a torque of 10 Nm).

ONS engine: after a 20-minute warm-up of the engine, tighten all bolts to a torque of 10 Nm.

2.0L DOHC engine

Attach a new rubber seal to the oil pan.

Attention. Ensure accurate seating of the gasket (guide lugs on the left and right of the O-ring holder).

Caution: After the sealant has been applied, the oil pan must be bolted on for no more than 20 minutes.

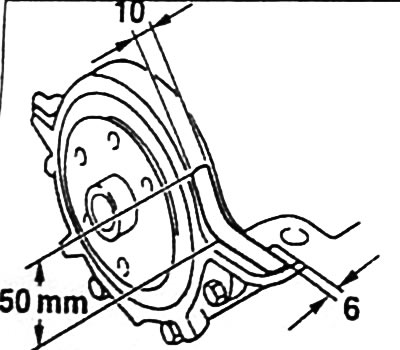

On the flywheel side, apply Hylosil 502 or Loctite 518 sealant to the crankcase. Apply a bead of sealant 3-5 mm thick and 10 mm wide on both sides.

Caution: The bead of sealant must completely cover the joints of the sealing surfaces.

Move the oil pan so that together with the crankcase it forms one surface at the end.

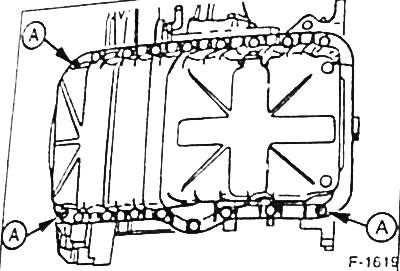

Attach oil pan. Apply Loctite 518 sealant to nuts and bolts, then screw them in and tighten them evenly, with a torque of 8-10 Nm (A: tighten the nuts on the studs to a torque of 6-8 Nm).

Engines with a displacement of 2.4 and 2.9 liters

Apply sealant FORD 85 TM 19554 AA to the joint at the end cover of the crankcase.

In the wedge groove of the rear main bearing cap, which must be absolutely clean, lay a little sealant as a lubricant.

Slide a new oil pan seal over the existing 6 studs. If this number of studs is not enough, screw in additional studs.

Attach oil pan. Tighten bolts and nuts by hand.

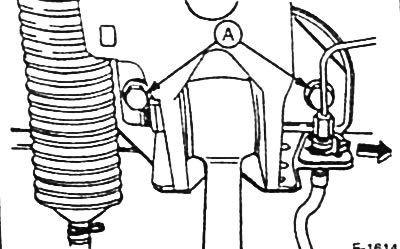

Attention: The spacer lugs -A- of the oil pan must be located in the corresponding grooves in the gasket.

Tighten the fastener in 2 steps:

- Reception 1: starting from position -A-, tighten all bolts to 5 Nm.

- Reception 2: starting from position -B-, tighten all bolts to 8 Nm.

Diesel engine

Glue the new oil pan seal to the crankcase with grease.

Caution: Make sure the gasket is in the correct position. Turbocharged diesel engine up to 8/93: Seal the oil pan with FORO SPM-2G9121-A Silicone Sealant.

Turbo diesel engine from 9/93: Seal the oil pan cover on the oil pan with silicone sealant and seal the oil pan on the crankcase with Loctite 510 or Loctite 518.

Attach oil pan and tighten fastener evenly to 10 Nm.

Petrol engine: install starter, see p. 167.

Attach the connecting beam and tighten the fastening bolts to a torque of 90 Nm.

Fasten the brake pipes to the connecting beam.

Connect the connecting joint to the steering shaft and tighten the retaining plate to 25 Nm.

Make sure the front wheels are in the straight ahead position with the steering wheel in the middle position. If this is not the case, release the lock plate again and turn the steering shaft in relation to the connecting shackle.

Lower the engine, while ensuring the correct position of its supports.

Tighten the engine mounting nuts to 70 Nm.

Fit the oil drain plug with a new O-ring and tighten to 25 Nm (for a diesel engine - a torque of 35 Nm).

Lower the car.

Attach and secure radiator air guide shroud.

Top up engine oil, see section "Maintenance".

Connect ground wire (-) battery.

If available, set the clock and enter the radio's anti-theft code.

Start the engine and let it run for about 20 minutes. Stop the engine and check the oil pan for leaks.

ONS engine: Tighten the oil pan bolts. Starting from position -A- (see figure TC/6A/39). Tighten all bolts to 10 Nm.

Visitor comments