This engine complies with EU Stage III emission standard (level III) and all other requirements for the latest generation of engines in terms of fuel consumption, smooth operation, elasticity and power.

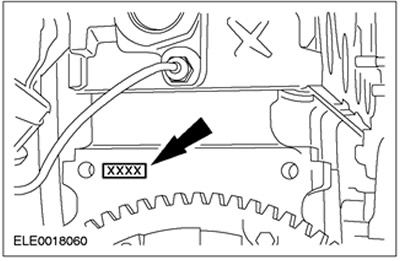

Engine codes

Engine code for Duratorq-TDCi:

- 85 kW (115 HP) F9DA

Location of the engine code on the cylinder block of the Duratorq-TDCi engine:

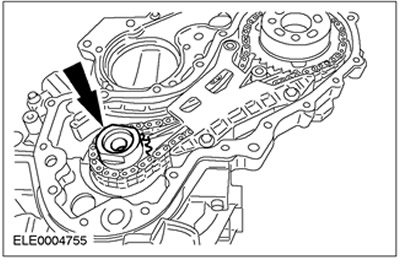

Crankshaft

The crankshaft, supported by five main bearings, has thrust half rings on the third main bearing, which determine the axial clearance of the crankshaft.

Timing sprocket located on the crankshaft

An asterisk located on the crankshaft drives the high pressure fuel pump sprocket through a chain drive.

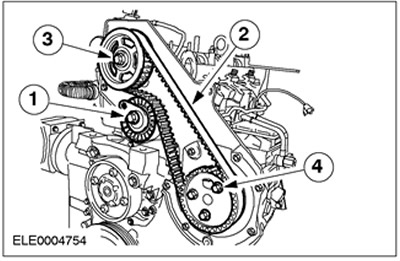

Belt drive of the gas distribution mechanism

| Pos. | Spare Part No | Name |

| 1 | - | Timing belt tensioner |

| 2 | - | Timing belt |

| 3 | - | Timing Belt Pulley |

| 4 | - | High pressure fuel pump pulley |

The timing belt is driven by the high pressure fuel pump pulley and transmits information about the opening or closing of the valves to the overhead camshaft.

CAUTION: Since a new timing belt will stretch considerably when it is first installed, the instructions for adjusting it must be followed exactly.

The timing belt tension is maintained by the automatic timing belt tensioner.

The pulley is fixed on the camshaft cone. The necessary force for fixing the pulley is created by a central bolt.

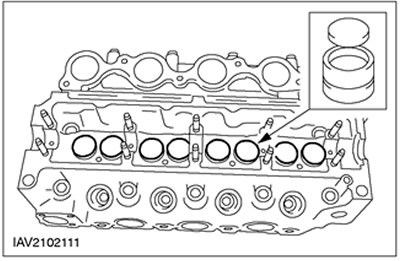

Valve lifter, shims (shims)

"Team" about the valve timing is transmitted to the valve springs by means of eight pushers.

CAUTION: When installing shims, the labels on the shims must face the tappets.

Shims are used to adjust valve clearances. The thickness of each gasket is indicated on its reverse side.

Cylinder head

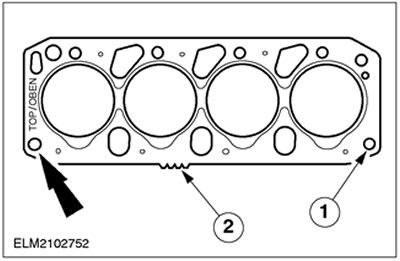

| Pos. | Spare Part No | Name |

| 1 | - | Hole for guide sleeve |

| 2 | - | Gasket Thickness Identification |

Cylinder head gaskets are available in various thicknesses. Depending on the protrusion of the pistons, a gasket of a certain thickness is installed on each specific engine. The thickness can be determined by the teeth on the edge of the gasket.

CAUTION: Completely clean the gasket and mating surfaces. Do not use sharp objects for cleaning.

Cylinder head gasket - type MLS gasket (laminated steel) The gasket consists of three steel layers. The steel layers have an outer rubber coating. Due to its design, the durability of the gasket is increased, and as a result of the fact that the gasket does not break in during installation, the cylinder head bolts can be inserted with a lower clamping force. However, due to the rubber surface, the gasket is also more susceptible to grooves and therefore the surface should be pre-cleaned without the use of sharp objects.

Crankshaft oil seals

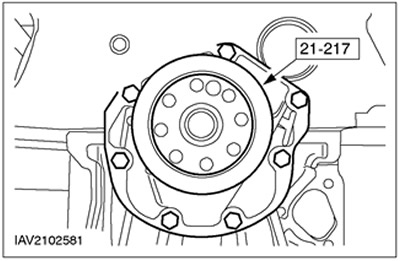

NOTE: The crankshaft rear oil seal comes with a seal holder. It should be checked using the special tool shown.

CAUTION: If the support ring is removed too early, the oil seal will shrink and become unusable.

Front and rear oil seals are made of PTFE. They must be clean when installed (unoiled).

Both oil seals are equipped with a support ring as an indispensable attribute. This ring should not be removed until the seal is finally installed, when it can fall out of the oil seal on its own.

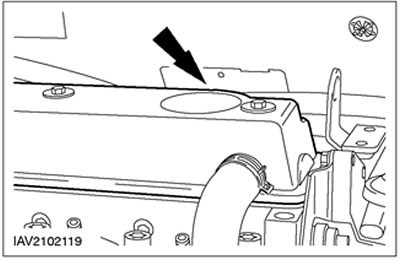

Crankcase ventilation

The crankcase ventilation valve is located on the top surface of the cylinder head cover. For optimum engine performance, this valve and all PCV hoses must always be clean and free of any dirt inside.

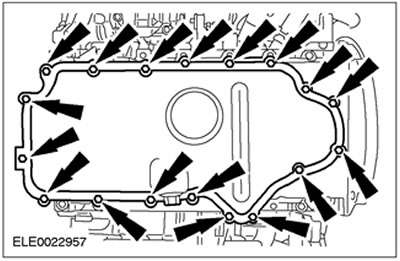

Oil sump

The oil sump is made of steel. It is sealed with silicone based sealant (WSE-M4G-323-A6).

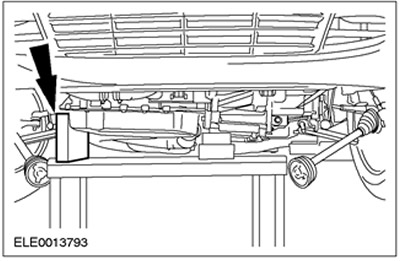

CAUTION: When removing the front engine mount, do not place a jack to support the engine under the oil sump.

CAUTION: Mount the engine/gearbox assembly with the subframe/oil sump flange on wooden blocks so as not to stress the oil sump.

If the engine is jacked up, the oil sump will be pushed inward. This may cause blockage in the oil supply to the oil inlet line.

The oil drain plug comes with an O-ring and can be reused many times.

Visitor comments