Attention! Clean the surface of the cap only when the caps are tightly closed to avoid contamination of the electrolyte.

Make sure that the corks are always tightly wrapped in the necks of the jars. At least once every two weeks, check the cleanliness of the gas outlet holes in the plugs (if they are fulfilled) side walls of the cover, as clogging of these openings will cause the gas pressure inside the battery to build up, which may damage the battery.

To prevent oxidation of the battery terminals and wire lugs, regularly clean the terminals and lugs, lubricate them with petroleum jelly or grease. Watch tightness of connection of tips of wires and conclusions.

Note. Instead of petroleum jelly or conventional greases, it is best to use commercially available conductive copper-containing greases to protect against oxidation of the leads and lugs.

Periodically check the reliability of the battery fastening on the car, if necessary, tighten it to avoid cracks on the monoblock.

Note. To reduce vibration transmitted to the battery monoblock and to avoid damage to the paintwork in the event of leakage of electrolyte from the battery, install the battery on an acid-resistant rubber mat.

The wires must be connected to the battery terminals with slack, as the tension of the wires can lead to loosening of the terminals in the cover and leakage of electrolyte.

Periodically, at least once every two weeks, check the electrolyte level in the battery cells.

Note. For batteries with a cover common to all cells, equipped with a capacitor cavity, it is allowed to check the electrolyte level once every 2 months.

The electrolyte level in all cells should be 5–10 mm higher than the upper edge of the separators, which corresponds to the level being between the marks «MIN» And «MAX» on the wall of the translucent battery case.

Note. It is convenient to check the electrolyte level above the upper edge of the separators with a glass tube: lower it into the cell until it stops in the separator and, closing the free end of the tube with your finger, remove it from the cell.

To restore the electrolyte level, add only distilled water. If it is determined that sloshing is the cause of the low level, then add electrolyte of the same density as that left in the battery cell. If the level is above normal, pump out the electrolyte with a rubber bulb with an ebonite tip.

Warning! It is strictly forbidden to add concentrated acid to the battery!

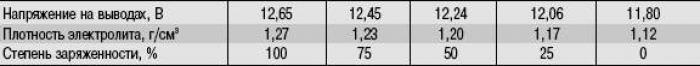

If during operation there are difficulties with starting the engine, check the state of charge battery by electrolyte density or voltage at its terminals in an unloaded state (tab. 4.5). Use a hydrometer or a commercially available electrolyte density float indicator to check the electrolyte density. The voltage at the battery terminals can be measured with any DC voltmeter with a measurement limit of 20 V (a similar voltmeter is included in all commercially available autotesters).

If the battery is 75% or less charged, remove it from the vehicle and charge it with a charger (see «Charging the battery»).

Table 4.5. Parameters for checking the state of charge of the battery

Visitor comments