|

STATES |

DETAILS/RESULTS/ACTIONS |

|

A1: INSPECTION OF TURBO ROTOR BLADES FOR DAMAGE |

|

|

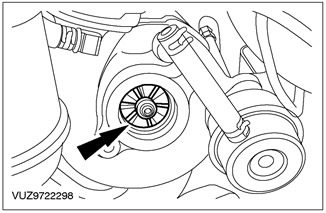

1 Disconnect the air filter outlet pipe from the turbocharger. |

|

|

2 Inspect the turbocharger rotor blades for damage. |

|

• Is there visible damage to the rotor blades? |

|

|

→ Yes |

|

|

Go to A2. |

|

|

→ No |

|

|

Go to A3. |

|

|

A2: CHECKING THE AIR INTAKE SYSTEM FOR FOREIGN MATERIAL |

|

|

1 Check air intake system components for signs of foreign material. |

|

|

• Are there any signs of foreign material? |

|

|

→ Yes |

|

|

CLEAN the air intake system components. INSTALL a new turbocharger. For more information, refer to Turbocharger - 75 HP Diesel Vehicles. or 90 hp / Turbocharger - Vehicles with 115 hp diesel engine available in this section. CHECK the system is working properly. |

|

|

→ No |

|

|

Go to A4. |

|

|

A3: CHECK TURBO BEARINGS FOR INCREASED PLAY |

|

|

NOTE: A little play in the bearings is normal. |

|

|

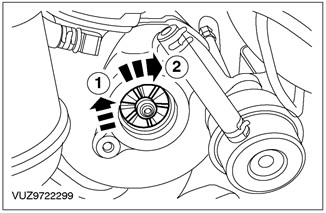

1 Check that the turbocharger rotor rotates freely in the housing. - 1. With the turbocharger stationary, gently lift the shaft (the shaft will naturally lie in the lower sections of the bearings). - 2. Check that the turbocharger rotor rotates freely in the housing. |

|

• Does the rotor rotate freely in the housing? |

|

|

→ Yes |

|

|

GO to ch. "Fuel supply and controls", which describes further diagnosis of blue smoke. See Section 303-04A / 303-04B / 303-04C / 303-04D / 303-04E / 303-04F / 303-04G for more information. |

|

|

→ No |

|

|

INSTALL a new turbocharger. For more information, refer to Turbocharger - 75 HP Diesel Vehicles. or 90 hp / Turbocharger - Vehicles with 115 hp diesel engine available in this section. CHECK the system is working properly. |

|

|

A4: CHECKING TURBOCOMPRESSOR OIL SUPPLY LINE FOR CLOCKAGE |

|

|

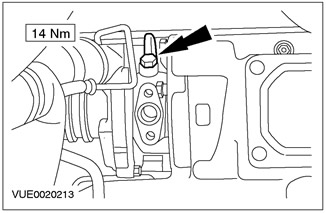

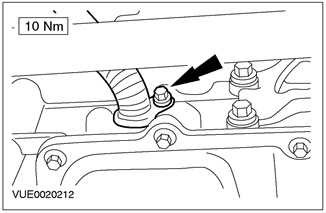

1 Disconnect the oil supply line from the turbocharger (for clarity, the catalytic converter and oil return line are shown in the removed position). |

|

2 Connect a small piece of known good hose to the oil supply line and carefully blow out the hose. |

|

|

• Are there any signs of blockage? |

|

|

→ Yes |

|

|

INSTALL a new turbocharger oil feed line. INSTALL a new turbocharger. For more information, refer to Turbocharger - 75 HP Diesel Vehicles. or 90 hp / Turbocharger - Vehicles with 115 hp diesel engine available in this section. CHECK the system is working properly. |

|

|

→ No |

|

|

INSTALL a new turbocharger. For more information, refer to Turbocharger - 75 HP Diesel Vehicles. or 90 hp / Turbocharger - Vehicles with 115 hp diesel engine available in this section. CHECK the system is working properly. |

|

PINPOINT TEST B: BLUE SMOKE WITHOUT INCREASED TURBO NOISE

|

STATES |

DETAILS/RESULTS/ACTIONS |

|

B1: TURBO OIL RETURN LINE INSPECTION |

|

|

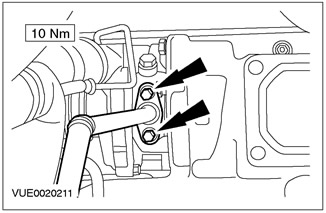

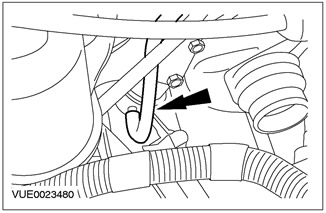

1 Disconnect the turbocharger oil return line from the turbocharger (catalytic converter not shown). |

|

2 Remove the turbocharger oil return line. |

|

3 Check the turbocharger oil return line for blockages or signs of damage. |

|

|

• Is the turbocharger oil return line OK? |

|

|

→ Yes |

|

|

GO to ch. "Fuel supply and controls", which describes further diagnosis of blue smoke. See Section 303-04A / 303-04B / 303-04C / 303-04D / 303-04E / 303-04F / 303-04G for more information. |

|

|

→ No |

|

|

INSTALL a new turbocharger oil return line. CHECK the system is working properly. |

|

PINPOINT TEST C: POOR ENGINE PERFORMANCE - VEHICLES WITH 75 HP DIESEL ENGINE OR 90 HP

|

STATES |

DETAILS/RESULTS/ACTIONS |

|

C1: CHECK TURBINE BYPASS VALVE ACTUATOR CONTROL PIPING FOR CLOCKAGE |

|

|

1 Remove the turbine bypass valve actuator control piping. |

|

|

2 Using a hand vacuum/pressure pump, connect one end to the turbine bypass actuator control line, operate the hand vacuum/pressure pump and observe the reading. |

|

|

• Is there an indication? |

|

|

→ Yes |

|

|

INSTALL a new turbine bypass valve actuator control line. CHECK the system is working properly. |

|

|

→ No |

|

|

Go to C2. |

|

|

C2: CHECK FOR LEAKAGE OF TURBINE BYPASS VALVE DIAPHRAGM ACTUATOR. |

|

|

1 Connect one end of the turbine bypass valve actuator control line to the turbine bypass valve actuator. |

|

|

2 Connect the other end of the turbine bypass valve actuator control line to the hand vacuum/charger pump. |

|

|

3 Operate the hand vacuum/pressure pump and observe the reading. |

|

|

• Does the pump hold a vacuum? |

|

|

→ Yes |

|

|

Go to C3. |

|

|

→ No |

|

|

INSTALL a new turbocharger. For more information, refer to Turbocharger - 75 HP Diesel Vehicles. or 90 hp available in this section. CHECK the system is working properly. |

|

|

C3: BOOST PRESSURE CHECK |

|

|

NOTE: Boost pressure is factory set and cannot be adjusted. |

|

|

1 Using a boost pressure gauge and a T-piece, connect a gauge between the turbo bypass valve actuator and the turbocharger. |

|

|

2 Start the engine and let it run until normal operating temperature is reached. |

|

|

3 Raise engine speed to 3000 rpm and observe readings. |

|

|

• Is the boost pressure less than 0.5 bar? |

|

|

→ Yes |

|

|

CHECK the fuel system. See Section 303-04A / 303-04B / 303-04C / 303-04D / 303-04E / 303-04F / 303-04G for more information. |

|

|

→ No |

|

|

INSTALL a new turbocharger. For more information, refer to Turbocharger - 75 HP Diesel Vehicles. or 90 hp available in this section. CHECK the system is working properly. |

|

PINPOINT TEST D: POOR ENGINE PERFORMANCE - VEHICLES WITH 115 HP DIESEL ENGINE

|

STATES |

DETAILS/RESULTS/ACTIONS |

|

D1: CHECK THE VACUUM LINE OF THE VACUUM DIAPHRAGM UNIT FOR CLOCKAGE |

|

|

1 Disconnect the vacuum line from the vacuum diaphragm assembly. |

|

2 Install the special tool and connect the vacuum line of the vacuum diaphragm unit. |

|

|

3 Operate the hand vacuum pump and observe the readings. |

|

|

• Is there an indication? |

|

|

→ Yes |

|

|

Go to D2. |

|

|

→ No |

|

|

INSTALL a new vacuum line to the vacuum diaphragm assembly. CHECK the system is working properly. |

|

|

D2: CHECK THE VACUUM DIAPHRAGM UNIT FOR LEAKAGE |

|

|

1 Install the special tool on the vacuum diaphragm assembly. |

|

|

2 Operate the hand vacuum pump and observe the readings. |

|

|

• Is the pump holding vacuum? |

|

|

→ Yes |

|

|

Go to D3. |

|

|

→ No |

|

|

INSTALL a new turbocharger. For more information, refer to Turbocharger - 115 HP Diesel Vehicles. available in this section. CHECK the system is working properly. |

|

|

D3: CHECKING VACUUM DIAPHRAGM UNIT ACTUATOR MOVEMENT |

|

|

1 Install the special tool on the diaphragm vane positioner. |

|

|

2 Operate the hand vacuum pump until a vacuum of 65 kPa is reached. Measure the distance traveled by the drive rod of the vacuum diaphragm assembly. |

|

|

• Does the drive rod of the vacuum diaphragm unit move within 9 - 11 mm? |

|

|

→ Yes |

|

|

REFER to WDS. |

|

|

→ No |

|

|

INSPECT for signs of damage or evidence of foreign material on turbocharger vanes. CHECK the system is working properly. |

|

Visitor comments