|

STATES |

DETAILS/RESULTS/ACTIONS |

|

E1: DEFINITION OF FAULTY CONDITIONS |

|

|

1 Drive the ON position. |

|

|

2 Toggle the heater fan switch through all positions. |

|

|

• Heater blower motor not running at all speed settings? |

|

|

→ Yes |

|

|

→ No |

|

|

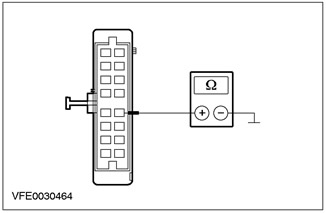

E2: CHECKING THE FUSE F64 |

|

|

1 Enter the OFF position. |

|

|

2 CHECK Fuse F64 (BJB). |

|

|

• Is the fuse good? |

|

|

→ Yes |

|

|

→ No |

|

|

REPLACE fuse F64 (40 A). CHECK the system is working properly. If the fuse blows again, FIND and REPAIR the short to «mass», using wiring diagrams. |

|

|

E3: FUSE VOLTAGE TEST F64 |

|

|

1 Connect F64 fuse (BJB). |

|

|

2 Drive the ON position. |

|

|

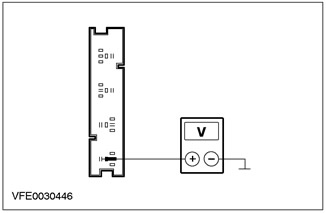

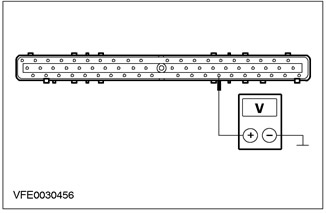

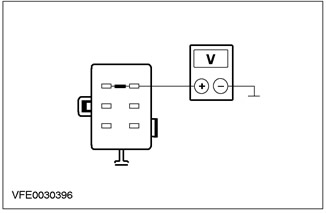

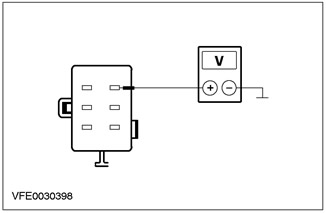

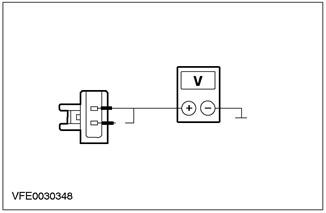

3 Check the voltage in the circuit between fuse F64 (40 A) And "weight". |

|

|

• Is battery voltage being recorded? |

|

|

→ Yes |

|

|

→ No |

|

|

RESTORE power to fuse F64 using the wiring diagrams. CHECK the system is working properly |

|

|

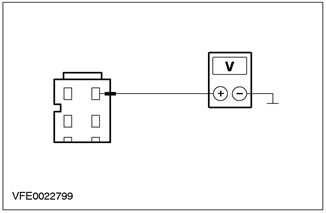

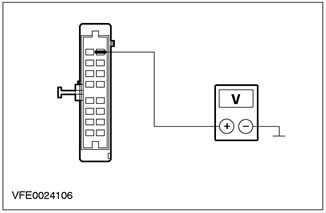

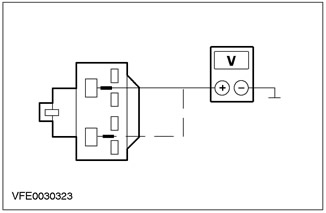

E4: VOLTAGE CHECK IN HEATER FAN MOTOR |

|

|

1 Enter the OFF position. |

|

|

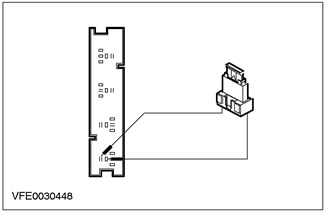

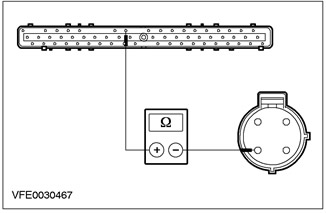

2 Disconnect the heater fan motor C789. |

|

|

3 Drive the ON position. |

|

|

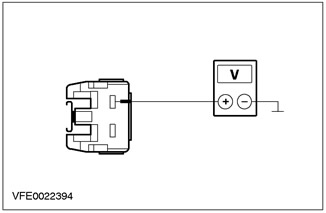

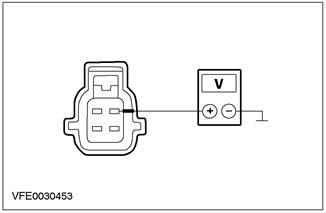

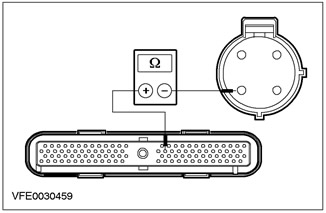

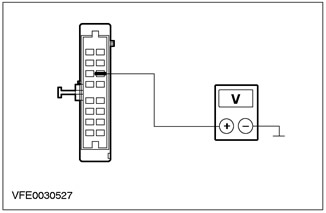

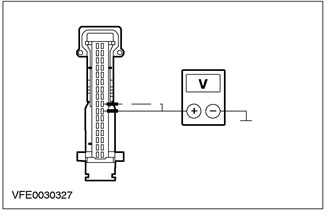

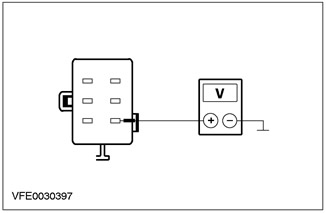

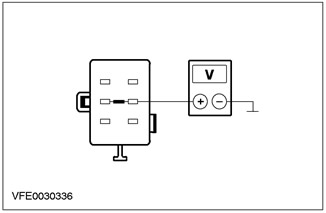

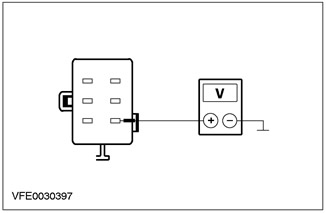

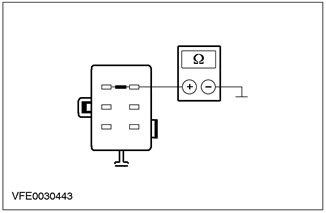

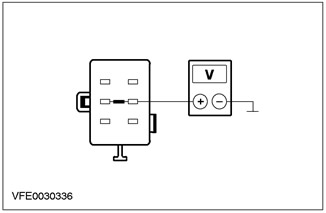

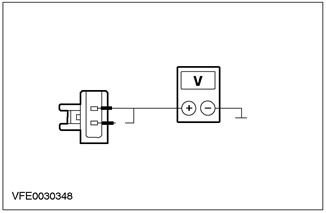

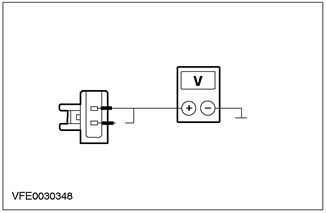

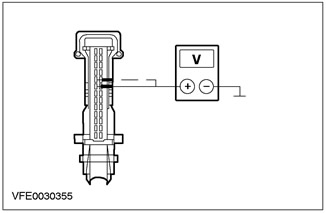

4 Measure the voltage between pin 1 of connector C789, heater fan circuit 15-FA18 (green-orange), on the wiring harness side, and «weight». |

|

• Is battery voltage being recorded? |

|

|

→ Yes |

|

|

→ No |

|

|

LOCATE and REPAIR the open circuit between the heater fan and the F64 fusible electrode using the wiring diagrams. CHECK the system is working properly |

|

|

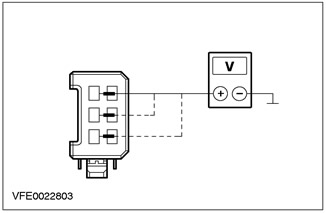

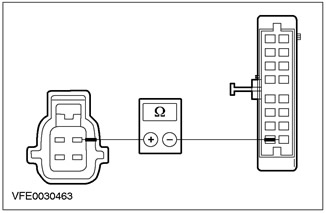

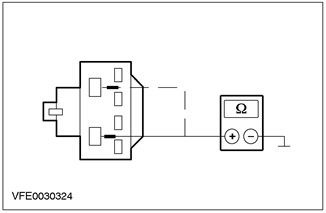

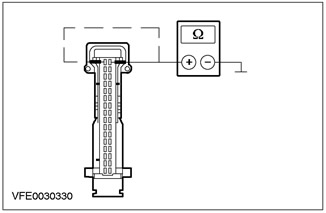

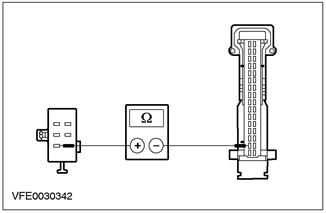

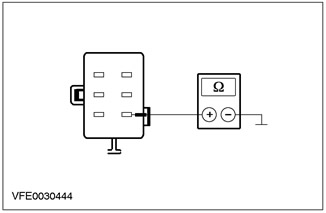

E5: HEATER ELECTRIC FAN GROUND CIRCUIT CHECK |

|

|

1 Enter the OFF position. |

|

|

2 Set the heater fan switch to "maximum". |

|

|

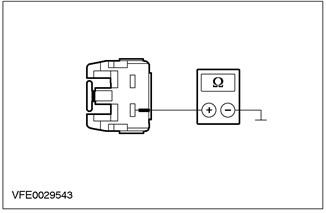

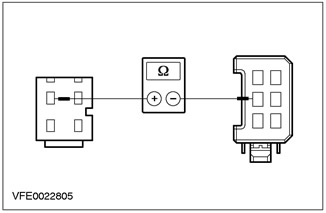

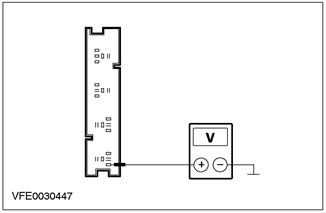

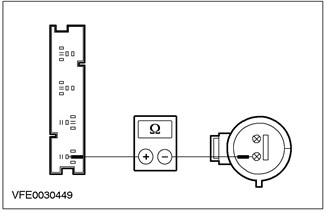

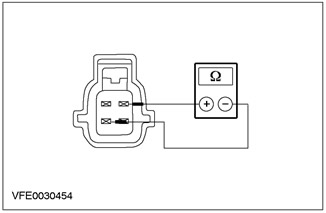

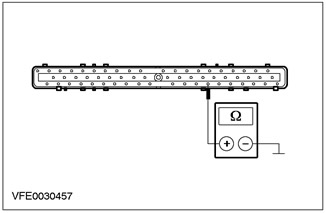

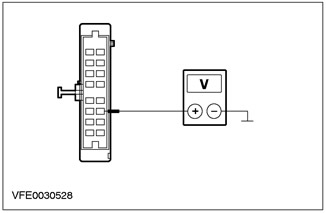

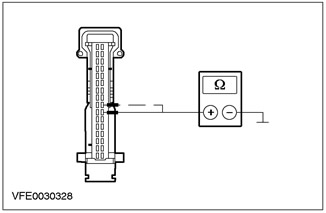

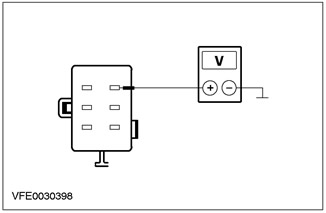

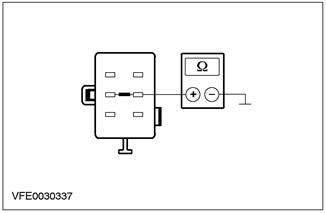

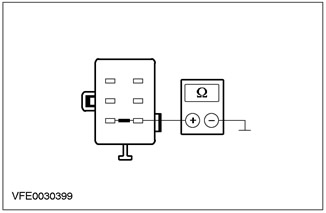

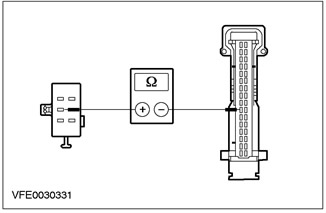

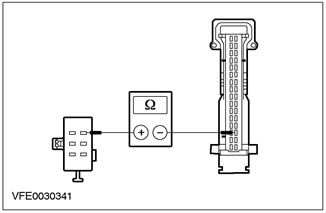

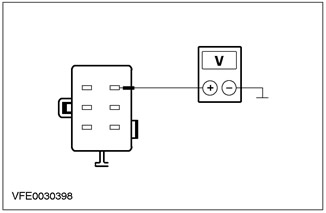

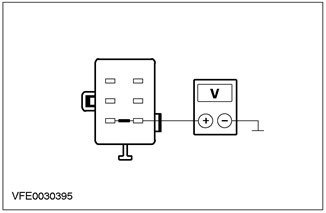

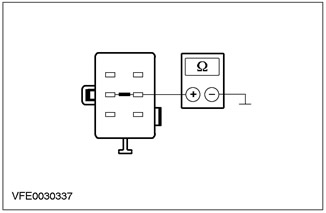

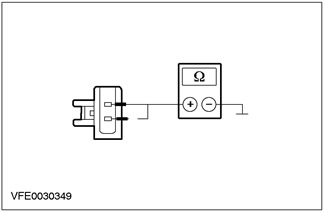

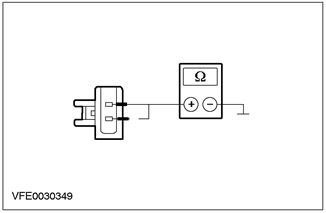

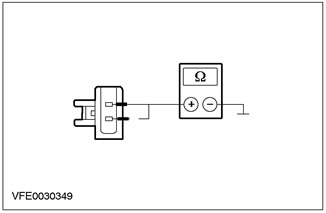

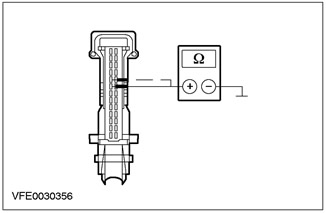

3 Measure the resistance between pin 2 of connector C789, heater fan, circuit 31S-FA18 (black and red), on the wiring harness side, and «weight». |

|

• Is the measured resistance less than 2 ohms? |

|

|

→ Yes |

|

|

REPLACE heater fan. CHECK the system is working properly |

|

|

→ No |

|

|

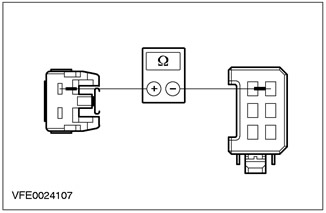

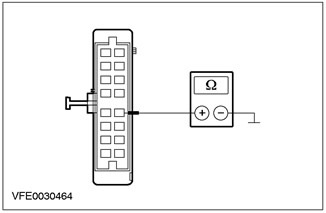

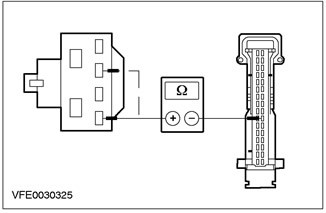

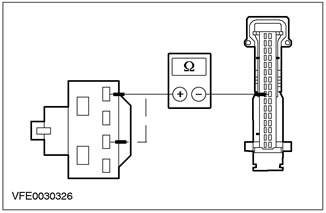

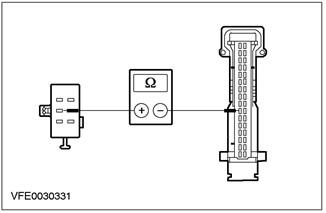

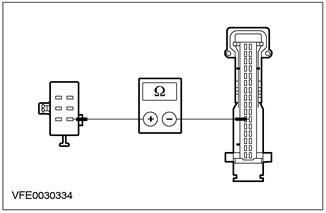

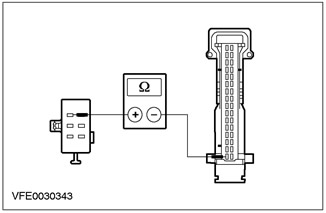

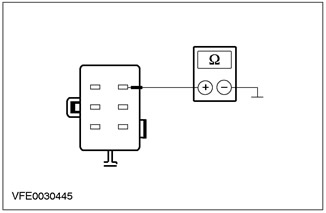

E6: CHECKING THE ELECTRICAL CIRCUIT BETWEEN THE HEATER ELECTRIC FAN AND THE HEATER FAN SWITCH |

|

|

1 Disconnect the C469 heater blower switch. |

|

|

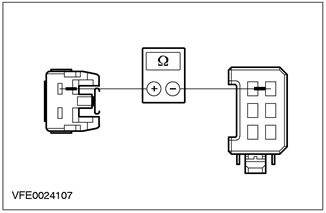

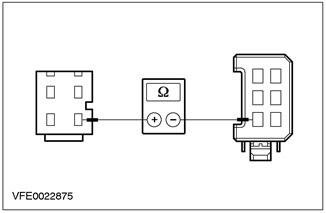

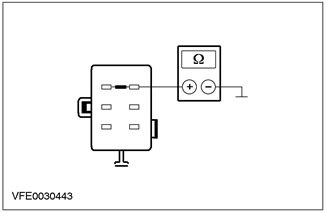

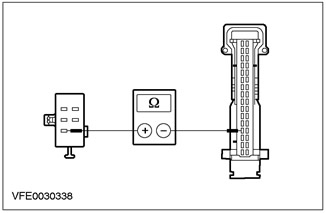

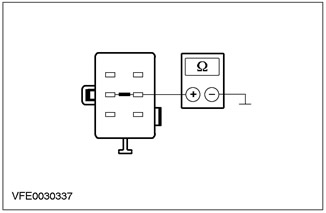

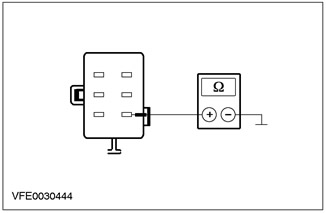

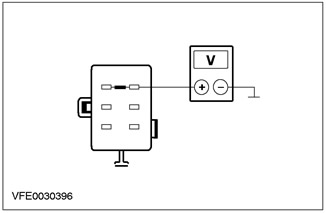

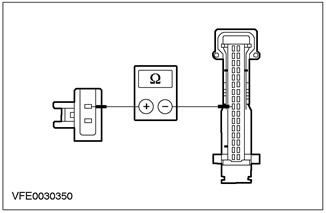

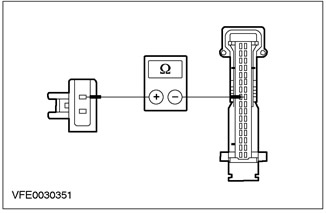

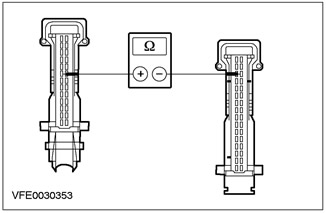

2 Measure the resistance between C789 heater fan motor pin 2, circuit 31S-FA18 (black and red), on the wiring harness side, and pin 6 C469 of the heater fan switch, circuit 31S-FA33 (black-orange), from the wiring harness side. |

|

• Is the measured resistance less than 2 ohms? |

|

|

→ Yes |

|

|

→ No |

|

|

LOCATE and REPAIR open circuit 31S-FA18 (black and red) between heater fan and solder joint S24 using the wiring diagrams. CHECK the system is working properly |

|

|

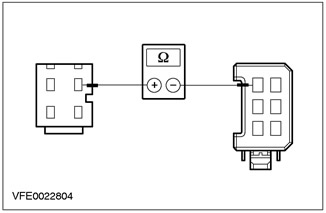

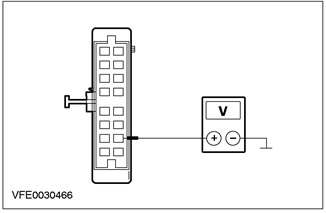

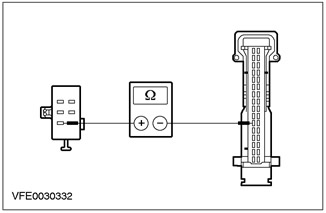

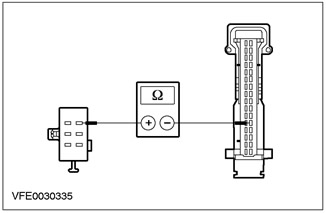

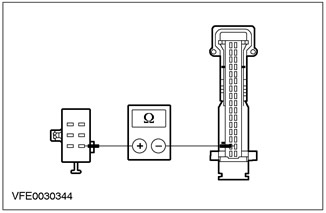

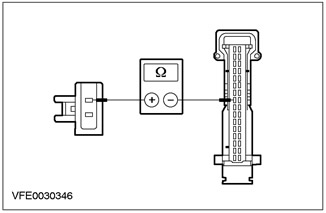

E7: HEATER FAN SWITCH GROUND ELECTRICAL CHECK |

|

|

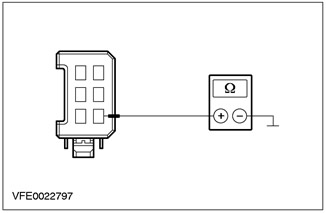

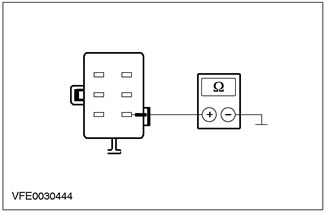

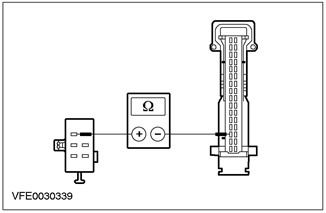

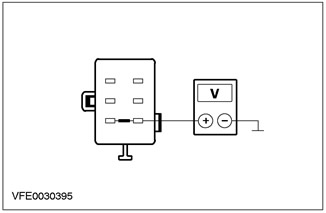

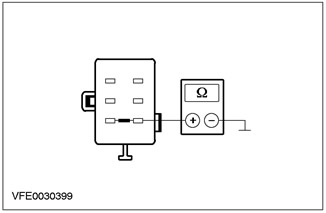

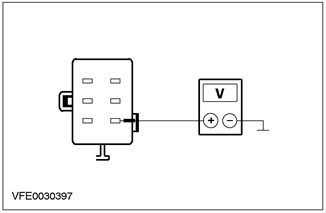

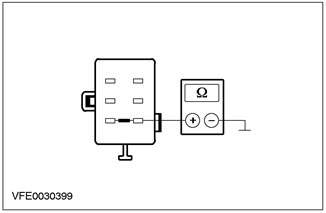

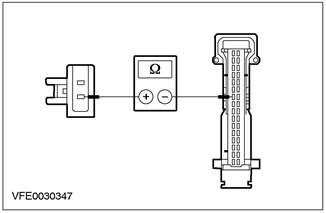

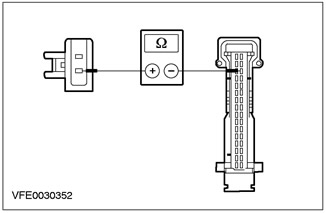

1 Measure the resistance between pin 2 of connector C469, heater blower switch, circuit 31-FA25 (black), on the wiring harness side, and «weight». |

|

• Is the measured resistance less than 2 ohms? |

|

|

→ Yes |

|

|

REPLACE heater blower switch. CHECK the system is working properly |

|

|

→ No |

|

|

LOCATE and REPAIR the open circuit between the heater blower switch and G14 ground using the wiring diagrams. CHECK the system is working properly |

|

|

E8: DEFINING THE CONDITIONS UNDER WHICH A FAULT OCCUR |

|

|

1 Set the heater fan switch to "maximum". |

|

|

• Heater blower motor not working? |

|

|

→ Yes |

|

|

→ No |

|

|

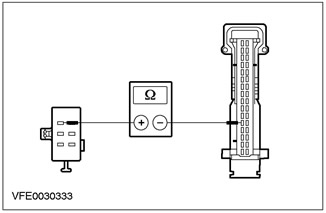

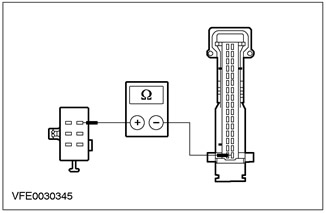

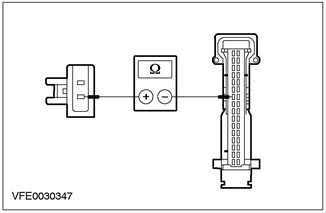

E9: CHECKING THE ELECTRICAL CIRCUIT BETWEEN THE HEATER ELECTRIC FAN AND THE HEATER FAN SWITCH |

|

|

1 Enter the OFF position. |

|

|

2 Disconnect the C469 heater blower switch. |

|

|

3 Disconnect the heater fan motor C789. |

|

|

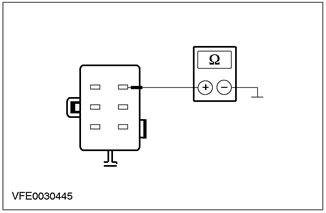

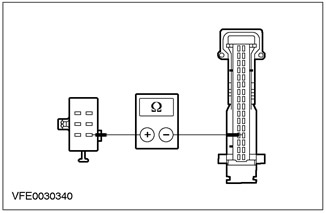

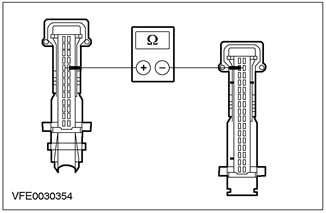

4 Measure the resistance between pin 2 of C789 heater fan circuit 31S-FA18 (black and red), on the wiring harness side, and pin 6 C469 of the heater fan switch, circuit 31S-FA33 (black-orange), from the wiring harness side. |

|

• Is the measured resistance less than 2 ohms? |

|

|

→ Yes |

|

|

REPLACE heater blower switch. CHECK the system is working properly |

|

|

→ No |

|

|

LOCATE and REPAIR open circuit 31S-FA33 (black-orange) between solder joint S24 and the heater blower switch, using the wiring diagrams. CHECK the system is working properly |

|

|

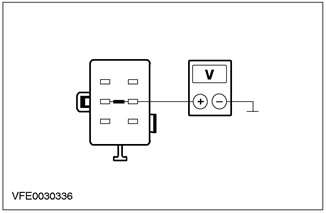

E10: HEATER FAN SWITCH CHECK |

|

|

1 Enter the OFF position. |

|

|

2 Disconnect the C469 heater blower switch. |

|

|

3 Drive the ON position. |

|

|

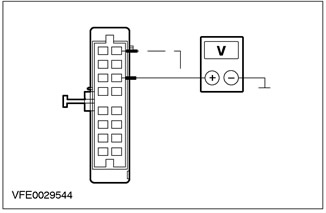

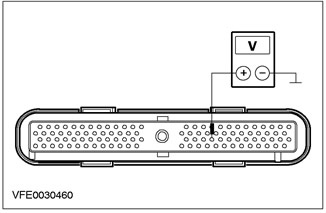

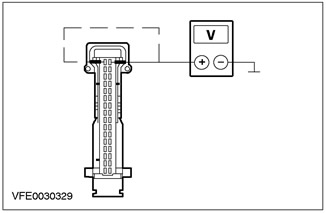

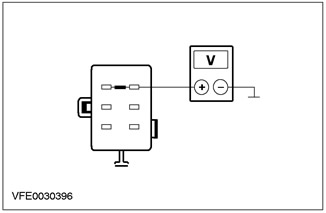

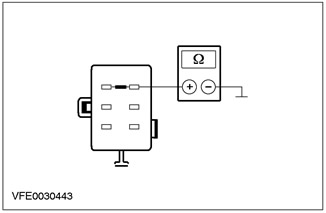

4 Measure the voltage between pin 5 of connector C469, heater blower switch, circuit 31S-FA32 (black and blue), on the wiring harness side, and «weight». |

|

5 Measure the voltage between pin 3 of connector C469, heater blower switch, circuit 31S-FA31 (black and yellow), on the wiring harness side, and «weight». |

|

|

6 Measure the voltage between pin 1 of connector C469, heater blower switch, circuit 31S-FA30 (black and white), on the wiring harness side, and «weight». |

|

|

• Is the battery voltage recorded in all cases? |

|

|

→ Yes |

|

|

REPLACE heater blower switch. CHECK the system is working properly |

|

|

→ No |

|

|

E11: CHECK THE ELECTRICAL CIRCUIT BETWEEN THE HEATER FAN MOTOR AND THE HEATER FAN VARIABLE RESISTOR |

|

|

1 Enter the OFF position. |

|

|

2 Disconnect the heater fan variable resistor C470. |

|

|

3 Drive the ON position. |

|

|

4 Measure the voltage between pin 1 of the C470 plug connector, heater fan variable resistor, circuit 31S-FA33 (black-orange), on the wiring harness side, and «weight». |

|

• Is battery voltage being recorded? |

|

|

→ Yes |

|

|

→ No |

|

|

LOCATE and REPAIR the open circuit between solder joint S24 and heater fan variable resistor using the wiring diagrams. CHECK the system is working properly |

|

|

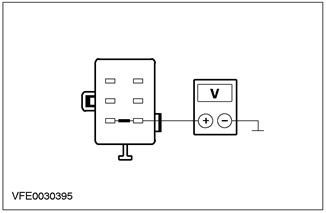

E12: CHECK THE ELECTRICAL CIRCUIT BETWEEN THE HEATER FAN VARIABLE RESISTOR AND THE HEATER FAN SWITCH |

|

|

1 Enter the OFF position. |

|

|

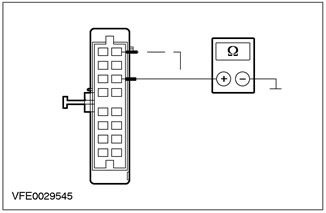

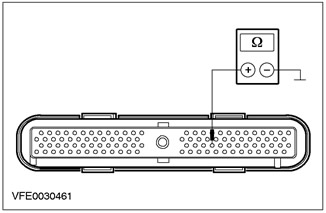

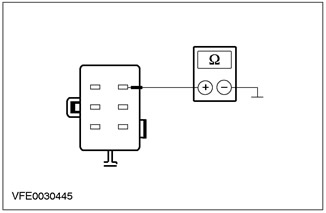

2 Measure the resistance between pin 4 of the heater fan variable resistor, connector C470, circuit 31S-FA32 (black and blue), on the wiring harness side, and pin 5 of connector C469, heater fan switch, circuit 31S-FA32 (black and blue), from the wiring harness side. |

|

• Is the measured resistance less than 2 ohms? |

|

|

→ Yes |

|

|

→ No |

|

|

LOCATE and REPAIR open circuit 31S-FA32 (black and blue) between the heater fan variable resistor and the heater fan switch, using the wiring diagrams. CHECK the system is working properly |

|

|

E13: CHECK THE ELECTRICAL CIRCUIT BETWEEN THE HEATER FAN VARIABLE RESISTOR AND THE HEATER FAN SWITCH |

|

|

1 Measure the resistance between pin 2 of connector C470 of heater fan variable resistor, circuit 31S-FA31 (black and yellow), on the wiring harness side, and pin 3 of connector C469, heater blower switch, circuit 31S-FA31 (black and yellow), from the wiring harness side. |

|

• Is the measured resistance less than 2 ohms? |

|

|

→ Yes |

|

|

→ No |

|

|

LOCATE and REPAIR open circuit 31S-FA31 (black and yellow) between the heater fan variable resistor and the heater fan switch, using the wiring diagrams. CHECK the system is working properly |

|

|

E14: CHECK THE ELECTRICAL CIRCUIT BETWEEN THE HEATER FAN VARIABLE RESISTOR AND THE HEATER FAN SWITCH |

|

|

1 Measure the resistance between pin 3 of plug connector C470 of heater fan variable resistor, circuit 31S-FA30 (black and white), on the wiring harness side, and pin 1 of connector C469, heater blower switch, circuit 31S-FA30 (black and white), from the wiring harness side. |

|

• Is the measured resistance less than 2 ohms? |

|

|

→ Yes |

|

|

REPLACE heater fan variable resistor. CHECK the system is working properly |

|

|

→ No |

|

|

LOCATE and REPAIR open circuit 31S-FA30 (black and white) between the heater fan variable resistor and the heater fan switch, using the wiring diagrams. CHECK the system is working properly |

|

PINPOINT TEST F: HEATER ELECTRIC FAN IS IN CONTINUOUS OPERATION (ONLY VEHICLES WITHOUT EATC)

|

STATES |

DETAILS/RESULTS/ACTIONS |

|

F1: HEATER FAN SWITCH TEST |

|

|

1 Enter the OFF position. |

|

|

2 Disconnect the C469 heater blower switch. |

|

|

3 Drive the ON position. |

|

|

• Is the heater blower motor running continuously? |

|

|

→ Yes |

|

|

Go to F2 |

|

|

→ No |

|

|

REPLACE heater blower switch. CHECK the system is working properly |

|

|

F2: CHECKING THE ELECTRICAL CIRCUITS IN THE VARIABLE RESISTOR OF THE HEATER FAN |

|

|

1 Enter the OFF position. |

|

|

2 Disconnect the heater fan variable resistor C470. |

|

|

3 Drive the ON position. |

|

|

• Is the heater blower motor running continuously? |

|

|

→ Yes |

|

|

CHECK all electrical circuits connected to solder joint S24 for shorts to «mass», using the wiring diagrams and REPAIR any short circuit found (I). CHECK the system is working properly |

|

|

→ No |

|

|

INSPECT all circuits between the heater fan variable resistor and the heater fan switch for a short to «mass», using the wiring diagrams and REPAIR any short circuit found (I). CHECK the system is working properly |

|

PINPOINT TEST G: INCORRECT FUNCTIONING OF THE AIR RECIRCULATION DAMPER (ONLY VEHICLES WITHOUT EATC)

|

STATES |

DETAILS/RESULTS/ACTIONS |

|

NOTE: The air recirculation damper is driven by a DC motor. After pressing the recirculation button, this DC motor is turned on by the heater control module for a maximum of 7 seconds. The air recirculation damper is opened and closed by changing the polarity of the applied voltage. |

|

|

NOTE: If the air distribution control switch is set to «anti-fogging / anti-icing windows», you cannot turn on the air recirculation mode. |

|

|

G1: VOLTAGE TEST OF AIR RECIRCULATION DAMPER POSITIONING MOTOR CIRCUIT |

|

|

1 Enter the OFF position. |

|

|

2 Disconnect the C538 air recirculation damper position motor. |

|

|

3 Drive the ON position. |

|

|

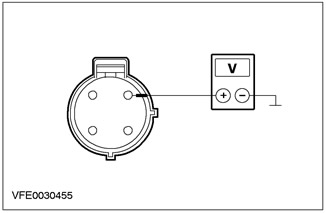

4 Measure the voltage between pins 2 and 4 of connector C538 of the air recirculation damper positioning motor, wiring harness side. |

|

|

5 During the measurement, press the air recirculation button several times. |

|

|

• Is a voltage of about 11 V detected with reverse polarity? |

|

|

→ Yes |

|

|

CHECK the air recirculation damper for freedom of movement and proper operation. If the air recirculation damper is mechanically OK, REPLACE the air recirculation damper positioning motor. CHECK the system is working properly |

|

|

→ No |

|

|

Go to G2 |

|

|

G2: CHECKING THE ELECTRICAL CIRCUIT BETWEEN THE HEATER CONTROL MODULE AND THE AIR RECIRCULATION DAMPER POSITIONING MOTOR |

|

|

1 Enter the OFF position. |

|

|

2 Disconnect the C380 heater control module. |

|

|

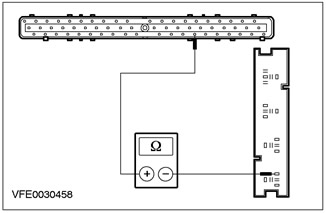

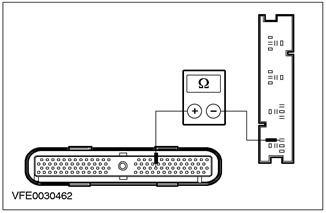

3 Measure the resistance between pin 16 of connector C380 of the heater control module, circuit 33-FA76 (yellow-blue), on the wiring harness side, and pin 2 of the C538 plug connector for the air recirculation damper positioning motor, circuit 33-FA76 (yellow-blue) (right hand drive vehicles: electrical circuit 32-FA76 (white-blue)), from the wiring harness side. |

|

|

• Is the measured resistance less than 2 ohms? |

|

|

→ Yes |

|

|

Go to G3 |

|

|

→ No |

|

|

LOCATE and REPAIR open circuit 33-FA76 (yellow-blue) (right hand drive vehicles: electrical circuit 32-FA76 (white-blue)) between the heater control module and the air recirculation damper positioning motor using the wiring diagrams. CHECK the system is working properly |

|

|

G3: CHECKING THE ELECTRICAL CIRCUIT BETWEEN THE HEATER CONTROL MODULE AND THE AIR RECIRCULATION DAMPER POSITIONING MOTOR |

|

|

1 Measure the resistance between the 14 pin connector C380 of the heater control module, circuit 32-FA76 (white-blue), on the wiring harness side, and pin 4 of the C538 plug connector for the air recirculation damper positioning motor, circuit 32-FA76 (white-blue) (right hand drive vehicles: electrical circuit 33-FA76 (yellow-blue)), from the wiring harness side. |

|

|

• Is the measured resistance less than 2 ohms? |

|

|

→ Yes |

|

|

Go to G4 |

|

|

→ No |

|

|

LOCATE and REPAIR open circuit 32-FA76 (white-blue) (right hand drive vehicles: electrical circuit 33-FA76 (yellow-blue)) between the heater control module and the air recirculation damper positioning motor using the wiring diagrams. CHECK the system is working properly |

|

|

G4: CHECK THE ELECTRICAL CIRCUIT BETWEEN THE HEATER CONTROL MODULE AND THE AIR RECIRCULATION FLAP POSITIONING MOTOR FOR A SHORT TO + OF THE BATTERY |

|

|

1 Drive the ON position. |

|

|

2 Measure the voltage between pin 14 of connector C380 of the heater control module, circuit 32-FA76 (white-blue), on the wiring harness side, and «weight». |

|

3 Measure the voltage between pin 16 of connector C380 of the heater control module, circuit 33-FA76 (yellow-blue), on the wiring harness side, and «weight». |

|

|

• Is voltage being registered? |

|

|

→ Yes |

|

|

LOCATE and REPAIR short to battery in circuit 32-FA76 (white-blue) or 33-FA76 (yellow-blue) between the heater control module and the air recirculation damper positioning motor using the wiring diagrams. CHECK the system is working properly |

|

|

→ No |

|

|

Go to G5 |

|

|

G5: CHECK THE ELECTRICAL CIRCUIT BETWEEN THE HEATER CONTROL MODULE AND THE AIR RECIRCULATION FLAP POSITIONING MOTOR FOR A SHORT TO « MASS » |

|

|

1 Enter the OFF position. |

|

|

2 Measure the resistance between pin 14 of connector C380 of the heater control module, circuit 32-FA76 (white-blue), on the wiring harness side, and «weight». |

|

3 Measure the resistance between pin 16 of connector C380 of the heater control module, circuit 33-FA76 (yellow-blue), on the wiring harness side, and «weight». |

|

|

• Is the measured resistance greater than 10 kΩ in both cases? |

|

|

→ Yes |

|

|

CHECK and if necessary REPLACE the heater control module. CHECK the system is working properly |

|

|

→ No |

|

|

FIND and REPAIR short circuit «mass» in the electrical circuit 32-FA76 (white-blue) or 33-FA76 (yellow-blue) between the heater control module and the air recirculation damper positioning motor using the wiring diagrams. CHECK the system is working properly |

|

PINPOINT TEST H: AIR CONDITIONING NOT WORKING (HEATER FAN OK)

|

STATES |

DETAILS/RESULTS/ACTIONS |

|

H1: REQUEST WDS TROUBLE CODES |

|

|

1 Enter the OFF position. |

|

|

2 Connect the diagnostic tool. |

|

|

3 Drive the START position. |

|

|

4 Query DTCs - run the engine control system diagnostic program using WDS. |

|

|

• Are there any DTCs? |

|

|

→ Yes |

|

|

PERFORM the necessary troubleshooting steps (to her) as directed by WDS. CHECK the system is working properly |

|

|

→ No |

|

|

Go to H2 |

|

|

H2: CHECK FUSE F15 |

|

|

1 Enter the OFF position. |

|

|

2CHECK Fuse F15 (BJB). |

|

|

• Is the fuse good? |

|

|

→ Yes |

|

|

Go to H3 |

|

|

→ No |

|

|

REPLACE fuse F15 (10 A). If the fuse blows again after turning on the A/C system, INSPECT the A/C compressor clutch diode and REPLACE it if necessary. If the diode is OK, FIND and REPAIR the short to «mass», using wiring diagrams. CHECK the system is working properly |

|

|

H3: FUSE VOLTAGE CHECK F15 |

|

|

1 Connect Fuse F15 (BJB). |

|

|

2 Check the voltage in the electrical circuit between fuse F15 (10 A) And "weight". |

|

|

• Is battery voltage being recorded? |

|

|

→ Yes |

|

|

Vehicles without EATC: Go to H4 |

|

|

Vehicles with EATC: Go to H8 |

|

|

→ No |

|

|

RESTORE power to fuse F15 using the wiring diagrams. CHECK the system is working properly |

|

|

H4: FUSE CHECK F36 |

|

|

1 CHECK Fuse F36 (CJB). |

|

|

• Is the fuse good? |

|

|

→ Yes |

|

|

Move to H5 |

|

|

→ No |

|

|

REPLACE fuse F36 (7,5 A). If the fuse blows again, FIND and REPAIR the short to «mass», using wiring diagrams. CHECK the system is working properly. |

|

|

H5: FUSE VOLTAGE TEST F36 |

|

|

1 Connect Fuse F36 (CJB). |

|

|

2 Check the voltage in the electrical circuit between fuse F36 (7,5 A) And "weight". |

|

|

• Is battery voltage being recorded? |

|

|

→ Yes |

|

|

Go to H6 |

|

|

→ No |

|

|

RESTORE power to fuse F36 using the wiring diagrams. CHECK the system is working properly. |

|

|

H6: FUSE CHECK F45 |

|

|

1 CHECK Fuse F45 (CJB). |

|

|

• Is the fuse good? |

|

|

→ Yes |

|

|

Go to H7 |

|

|

→ No |

|

|

REPLACE fuse F45 (7,5 A). If the fuse blows again, FIND and REPAIR the short to «mass», using wiring diagrams. CHECK the system is working properly. |

|

|

H7: FUSE VOLTAGE TEST F45 |

|

|

1 Connect Fuse F45 (CJB). |

|

|

2 Drive the ON position. |

|

|

3 Check the voltage in the electrical circuit between fuse F45 (7,5 A) And "weight". |

|

|

• Is battery voltage being recorded? |

|

|

→ Yes |

|

|

Go to H8 |

|

|

→ No |

|

|

RESTORE power to fuse F45 using the wiring diagrams. CHECK the system is working properly. |

|

|

H8: CHECK THE SUPPLY VOLTAGE TO A/C WOT RELAY |

|

|

1 Enter the OFF position. |

|

|

2 Disconnect C1011 A/C WOT relay (BJB). |

|

|

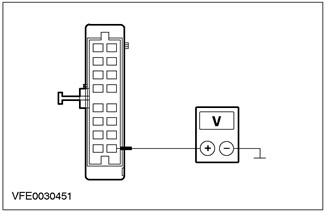

3 Measure the voltage on the circuit between pin 3 of connector C1011 of the A/C WOT relay, circuit 15-FA38 (green-red), on the wiring harness side, and «weight». |

|

• Is battery voltage being recorded? |

|

|

→ Yes |

|

|

Move to H9 |

|

|

→ No |

|

|

LOCATE and REPAIR open circuit 15-FA38 (green-red) between fuse F15 and A/C WOT relay using the wiring diagrams. CHECK the system is working properly. |

|

|

H9: CHECKING THE CONTROL VOLTAGE IN A/C WOT RELAY |

|

|

1 Drive the START position. |

|

|

2 Measure the voltage in the circuit between pin 1 of connector C1011 of the A/C WOT relay, circuit 15-FA11 (green-yellow), on the wiring harness side, and «weight». |

|

• Is battery voltage being recorded? |

|

|

→ Yes |

|

|

Go to H10 |

|

|

→ No |

|

|

LOCATE and REPAIR open circuit 15-FA11 (green-yellow) between solder joint S117 and the A/C WOT relay using the wiring diagrams. CHECK the system is working properly. |

|

|

H10: A/C COMPRESSOR CLUTCH CIRCUIT CHECK |

|

|

1 Enter the OFF position. |

|

|

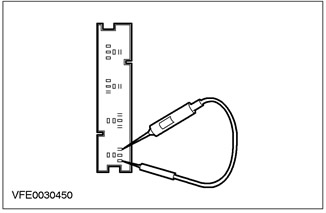

2 Use a fused test lead (10 A), to bridge pins 3 and 5 of connector C1011 of the A/C WOT relay, harness side. |

|

3 Drive the START position. |

|

|

4 Check A/C compressor clutch operation. |

|

|

• Is the A/C compressor clutch working? |

|

|

→ Yes |

|

|

Go to H13 |

|

|

→ No |

|

|

Go to H11 |

|

|

H11: CHECK THE ELECTRICAL CIRCUIT BETWEEN A/C WOT RELAY AND A/C COMPRESSOR CLUTCH FOR OPEN |

|

|

1 Enter the OFF position. |

|

|

2 Disconnect the C952 A/C compressor clutch. |

|

|

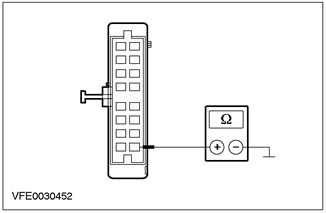

3 Measure the resistance between A/C WOT relay connector C1011 pin 5, harness side, and A/C compressor clutch C952 pin 1, circuit 15S-FA6 (green-yellow), from the wiring harness side. |

|

• Is the measured resistance less than 2 ohms? |

|

|

→ Yes |

|

|

Go to H12 |

|

|

→ No |

|

|

LOCATE and REPAIR the open circuit between the A/C WOT relay and the A/C compressor clutch using the wiring diagrams. CHECK the system is working properly. |

|

|

H12: COMPRESSOR A/C CLUTCH GROUND ELECTRICAL CHECK |

|

|

1 Measure the resistance between pin 2 of connector C952 of A/C compressor clutch, circuit 31-FA6 (black), on the wiring harness side, and «weight». |

|

• Is the measured resistance less than 2 ohms? |

|

|

→ Yes |

|

|

REPLACE A/C compressor clutch. CHECK the system is working properly. |

|

|

→ No |

|

|

LOCATE and REPAIR the open circuit between the A/C compressor clutch and ground point G56 using the wiring diagrams. CHECK the system is working properly. |

|

|

H13: A/C WOT RELAY GROUND ELECTRICAL CHECK |

|

|

1 Turn on the heater fan. |

|

|

2 Turn on the air conditioning system. |

|

|

CAUTION: A test lamp rated at 12V and rated at 1.2W must be used when performing the following test. Otherwise, the PCM may be damaged or the test will give incorrect results. 3 Use test lamp to check voltage between pins 1 and 2 of connector C1011 of A/C WOT relay (12 V, 1.2 W). |

|

• Is the indicator lamp on? |

|

|

→ Yes |

|

|

REPLACE A/C WOT relay. CHECK the system is working properly. |

|

|

→ No |

|

|

Go to H14 |

|

|

H14: CHECKING THE QUANTITY OF REFRIGERANT |

|

|

1 Enter the OFF position. |

|

|

2 Check the amount of refrigerant in the system. REFER to 346202 in this section. |

|

|

• Does the amount of refrigerant in the system match the manufacturer's specifications? |

|

|

→ Yes |

|

|

Go to H15 |

|

|

→ No |

|

|

CHARGE the system with the correct amount of refrigerant. CHECK the system for leaks and CHECK the operation of the system. |

|

|

H15: CHECK THE ELECTRICAL CIRCUIT BETWEEN THE HEATER CONTROL MODULE OR EATC MODULE AND THE PCM FOR A SHORT TO + OF THE BATTERY |

|

|

1 Disconnect the C380 heater control module or EATC module. |

|

|

2 Disconnect C416 PCM (or C415 with 104-pin EEC V). |

|

|

3 Drive the ON position. |

|

|

4 Measure voltage between pin 9 of connector C380 of heater control module or EATC module, circuit 15S-FA38 (green-red), on the wiring harness side, and «weight». |

|

• Is voltage being registered? |

|

|

→ Yes |

|

|

LOCATE and REPAIR short to + battery in circuit 15S-FA38 (green-red), 15S-FA 17 (green-orange) or 15S-RE 8 (green-yellow) between the heater control module and the PCM using the wiring diagrams. CHECK the system is working properly. |

|

|

→ No |

|

|

Go to H16 |

|

|

H16: CHECK THE ELECTRICAL CIRCUIT BETWEEN HEATER CONTROL OR EATC MODULE AND PCM FOR A SHORT TO « MASS » |

|

|

1 Enter the OFF position. |

|

|

2 Measure the resistance between pin 8 of connector C380 of the heater control module or EATC module, circuit 15S-FA38 (green-red), on the wiring harness side, and «weight». |

|

• Is the measured resistance less than 10,000 ohms? |

|

|

→ Yes |

|

|

FIND and REPAIR short circuit «mass» in the electrical circuit 15S-FA38 (green-red), 15S-FA 17 (green-orange) or 15S-RE 8 (green-yellow) between the heater control module or the EATC module and the PCM using the wiring diagrams. CHECK the system is working properly. |

|

|

→ No |

|

|

Go to H17 |

|

|

H17: VOLTAGE TEST IN DOUBLE PRESSURE SWITCH |

|

|

1 Connect C380 heater control module or EATC module. |

|

|

2 Connect C416 PCM (or C415 with 104-pin EEC V). |

|

|

3 Disconnect Dual Pressure Switch C882. |

|

|

4 Drive the START position. |

|

|

5 Turn on the heater fan. |

|

|

6 Turn on the air conditioning system. |

|

|

7 Measure the voltage between pin 1 of the C882 plug connector of the double relay, circuit 15S-FA38 (green-red), on the wiring harness side, and «weight». |

|

• Is battery voltage being recorded? |

|

|

→ Yes |

|

|

Go to H18 |

|

|

→ No |

|

|

Go to H29 |

|

|

H18: TESTING THE DUAL PRESSURE SWITCH |

|

|

1 Enter the OFF position. |

|

|

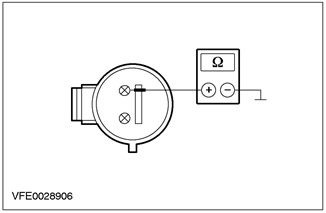

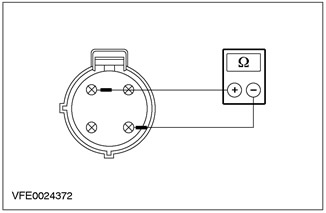

2 Measure the resistance between pins 1 and 4 of connector C882 on the dual pressure switch, element side. |

|

• Is the measured resistance less than 2 ohms? |

|

|

→ Yes |

|

|

Go to H19 |

|

|

→ No |

|

|

REPLACE dual pressure switch. CHECK the system is working properly. |

|

|

H19: VOLTAGE CHECK IN A/C COMPRESSOR SWITCH |

|

|

1 Connect the C882 dual pressure switch. |

|

|

2 Disconnect the C692 A/C compressor switch. |

|

|

3 Drive the START position. |

|

|

4 Turn on the heater fan. |

|

|

5 Turn on the air conditioning system. |

|

|

6 Measure the voltage between pin 1 of connector C692 of the A/C compressor switch, circuit 15S-FA17 (green-orange), on the wiring harness side, and «weight». |

|

• Is battery voltage being recorded? |

|

|

→ Yes |

|

|

Go to H20 |

|

|

→ No |

|

|

LOCATE and REPAIR open circuit 15S-FA17 (green-orange) between the dual pressure switch and the air conditioning compressor switch using the wiring diagrams. CHECK the system is working properly. |

|

|

H20: A/C COMPRESSOR SWITCH CHECK |

|

|

1 Enter the OFF position. |

|

|

2 Measure the resistance between pins 1 and 4 of connector C692 of the air conditioning compressor switch, element side. |

|

• Is the measured resistance less than 2 ohms? |

|

|

→ Yes |

|

|

Vehicles with EEC V (60-pin): Move to H21 |

|

|

Vehicles with EEC V (104-pin): Go to H25 |

|

|

→ No |

|

|

Replace A/C compressor switch. CHECK the system is working properly. |

|

|

H21: CHECK CIRCUIT BETWEEN A/C COMPRESSOR SWITCH AND PCM FOR OPEN |

|

|

1 Disconnect PCM C416. |

|

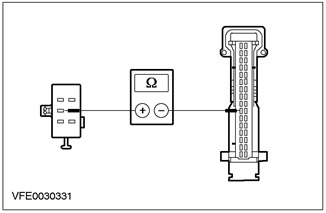

2 Measure the resistance between pin 10 of connector C416 PCM, circuit 15S-RE8 (green-yellow), on the wiring harness side, and pin 4 of connector C692 of the A/C compressor switch, circuit 15S-RE8 (green-yellow), from the wiring harness side. |

|

|

• Is the measured resistance less than 2 ohms? |

|

|

→ Yes |

|

|

Go to H22 |

|

|

→ No |

|

|

LOCATE and REPAIR open circuit 15S-RE8 (green-yellow) between the A/C compressor switch and the PCM using the wiring diagrams. CHECK the system is working properly. |

|

|

H22: CHECK THE ELECTRICAL CIRCUIT BETWEEN A/C WOT RELAY AND PCM FOR A SHORT TO + BATTERY |

|

|

1 Drive the ON position. |

|

|

2 Measure the voltage between pin 54 of connector C416 PCM, circuit 31S-FA11 (black and yellow), on the wiring harness side, and «weight». |

|

• Is voltage being registered? |

|

|

→ Yes |

|

|

LOCATE and REPAIR short to battery in circuit 31S-FA11 (black and yellow) between the A/C WOT relay and the PCM using the wiring diagrams. CHECK the system is working properly. |

|

|

→ No |

|

|

Go to H23 |

|

|

H23: CHECK THE ELECTRICAL CIRCUIT BETWEEN A/C WOT RELAY AND PCM FOR A SHORT TO « MASS » |

|

|

1 Enter the OFF position. |

|

|

2 Measure the resistance between pin 54 of connector C416 PCM, circuit 31S-FA11 (black and yellow), on the wiring harness side, and «weight». |

|

• Is the measured resistance less than 10,000 ohms? |

|

|

→ Yes |

|

|

FIND and REPAIR short circuit «mass» in the electrical circuit 31S-FA11 (black and yellow) between the A/C WOT relay and the PCM using the wiring diagrams. CHECK the system is working properly. |

|

|

→ No |

|

|

Go to H24 |

|

|

H24: CHECK THE ELECTRICAL CIRCUIT BETWEEN A/C WOT RELAY AND PCM FOR OPEN |

|

|

1 Measure the resistance between pin 54 of connector C416 PCM, circuit 31S-FA11 (black and yellow), on the wiring harness side, and pin 2 of connector C1011 of the A/C WOT relay, on the wiring harness side. |

|

• Is the measured resistance less than 2 ohms? |

|

|

→ Yes |

|

|

CHECK and REPLACE PCM if necessary. CHECK the system is working properly. |

|

|

→ No |

|

|

LOCATE and REPAIR the open circuit between the A/C WOT relay and the PCM using the wiring diagrams. CHECK the system is working properly. |

|

|

H25: CHECK CIRCUIT BETWEEN A/C COMPRESSOR SWITCH AND PCM FOR OPEN |

|

|

1 Disconnect PCM C415. |

|

|

2 Measure the resistance between pin 41 of connector C415 PCM, circuit 15S-RE8 (green-yellow), on the wiring harness side, and pin 4 of connector C692 of the A/C compressor switch, circuit 15S-RE8 (green-yellow), from the wiring harness side. |

|

• Is the measured resistance less than 2 ohms? |

|

|

→ Yes |

|

|

Go to H26 |

|

|

→ No |

|

|

LOCATE and REPAIR open circuit 15S-RE8 (green-yellow) between the A/C compressor switch and the PCM using the wiring diagrams. CHECK the system is working properly. |

|

|

H26: CHECK THE ELECTRICAL CIRCUIT BETWEEN A/C WOT RELAY AND PCM FOR A SHORT TO + BATTERY |

|

|

1 Drive the ON position. |

|

|

2 Measure the voltage between C415 PCM connector pin, circuit 31S-FA11 (black and yellow), on the wiring harness side, and «weight». |

|

• Is voltage being registered? |

|

|

→ Yes |

|

|

LOCATE and REPAIR short to battery in circuit 31S-FA11 (black and yellow) between the A/C WOT relay and the PCM using the wiring diagrams. CHECK the system is working properly. |

|

|

→ No |

|

|

Go to H27 |

|

|

H27: CHECK THE ELECTRICAL CIRCUIT BETWEEN A/C WOT RELAY AND PCM FOR A SHORT TO « MASS » |

|

|

1 Enter the OFF position. |

|

|

2 Measure the resistance between pin 69 of connector C415 PCM, circuit 31S-FA11 (black and yellow), on the wiring harness side, and «weight». |

|

• Is the measured resistance less than 10,000 ohms? |

|

|

→ Yes |

|

|

FIND and REPAIR short circuit «mass» in the electrical circuit 31S-FA11 (black and yellow) between the A/C WOT relay and the PCM using the wiring diagrams. CHECK the system is working properly. |

|

|

→ No |

|

|

Go to H28 |

|

|

H28: CHECK CIRCUIT BETWEEN A/C WOT RELAY AND PCM FOR OPEN |

|

|

1 Measure the resistance between pin 69 of connector C415 PCM, circuit 31S-FA11 (black and yellow), on the wiring harness side, and pin 2 of connector C1011 of the A/C WOT relay, on the wiring harness side. |

|

• Is the measured resistance less than 2 ohms? |

|

|

→ Yes |

|

|

CHECK and REPLACE PCM if necessary. CHECK the system is working properly. |

|

|

→ No |

|

|

LOCATE and REPAIR the open circuit between the A/C WOT relay and the PCM using the wiring diagrams. CHECK the system is working properly. |

|

|

H29: CHECK THE ELECTRICAL CIRCUIT BETWEEN THE DUAL PRESSURE SWITCH AND THE HEATER CONTROL MODULE OR EATC MODULE FOR OPEN |

|

|

1 Enter the OFF position. |

|

|

2 Disconnect the C380 heater control module or EATC module. |

|

|

3 Measure the resistance between pin 1 of connector C882 of the dual pressure switch circuit 15S-FA38 (green-red), on the wiring harness side, and pin 9 of connector C380 of the heater control module or EATC module, circuit 15S-FA38 (green-red), from the wiring harness side. |

|

• Is the measured resistance less than 2 ohms? |

|

|

→ Yes |

|

|

Vehicles without EATC: Go to H30 |

|

|

Vehicles with EATC: INSPECT and if necessary REPLACE the EATC module. CHECK the system is working properly. |

|

|

→ No |

|

|

LOCATE and REPAIR open circuit 15S-FA38 (green-red) between the dual pressure switch and the heater control module or EATC module using the wiring diagrams. CHECK the system is working properly. |

|

|

H30: CHECK THE GROUND CIRCUIT OF THE HEATER CONTROL MODULE |

|

|

1 Measure the resistance between pin 12 of connector C380 of the heater control module, circuit 91-FA13 (black-orange), on the wiring harness side, and «weight». |

|

• Is the measured resistance less than 2 ohms? |

|

|

→ Yes |

|

|

Go to H31 |

|

|

→ No |

|

|

LOCATE and REPAIR the open circuit between the heater control module and ground point G41 using the wiring diagrams. CHECK the system is working properly. |

|

|

H31: VOLTAGE CHECK IN THE HEATER CONTROL MODULE |

|

|

1 Measure the voltage between pin 8 of connector C380 of the heater control module, wiring harness side, and «weight». |

|

• Is battery voltage being recorded? |

|

|

→ Yes |

|

|

Go to H32 |

|

|

→ No |

|

|

LOCATE and REPAIR the open circuit between the heater control module and fuse F36 using the wiring diagrams. CHECK the system is working properly. |

|

|

H32: VOLTAGE CHECK IN THE HEATER CONTROL MODULE |

|

|

1 Drive the ON position. |

|

|

2 Measure the voltage between pin 10 of connector C380 of the heater control module, harness side, and «weight». |

|

• Is battery voltage being recorded? |

|

|

→ Yes |

|

|

Go to H33 |

|

|

→ No |

|

|

LOCATE and REPAIR the open circuit between the heater control module and fuse F45 using the wiring diagrams. CHECK the system is working properly. |

|

|

H33: CHECK THE CONTROL VOLTAGE IN THE HEATER CONTROL MODULE |

|

|

1 Set the heater fan switch to "OFF" ("off"). |

|

|

2 Measure the voltage between pin 6 of connector C380 of the heater control module, circuit 31S-FA26 (black and red), on the wiring harness side, and «weight». |

|

• Is battery voltage being recorded? |

|

|

→ Yes |

|

|

Go to H34 |

|

|

→ No |

|

|

LOCATE and REPAIR open circuit 31S-CA26 (black and red) between the heater control module and the heater fan switch using the wiring diagrams. CHECK the system is working properly. |

|

|

H34: VOLTAGE CHECK IN THE HEATER CONTROL MODULE |

|

|

1 Drive the START position. |

|

|

2 Measure the voltage between pin 11 of connector C380 of the heater control module, harness side, and «weight». |

|

• Is battery voltage being recorded? |

|

|

→ Yes |

|

|

CHECK and if necessary REPLACE the heater control module. CHECK the system is working properly. |

|

|

→ No |

|

|

LOCATE and REPAIR the open circuit between the heater control module and the engine run relay using the wiring diagrams. CHECK the system is working properly. |

|

PINPOINT TEST I: EATC MODULE NOT WORKING (NO INDICATION ON THE CONTROL UNIT DISPLAY)

|

STATES |

DETAILS/RESULTS/ACTIONS |

|

I1: FUSE CHECK F36 |

|

|

1 Enter the OFF position. |

|

|

2 CHECK Fuse F36 (CJB). |

|

|

• Is the fuse good? |

|

|

→ Yes |

|

|

Go to I2 |

|

|

→ No |

|

|

REPLACE fuse F36 (7,5 A). CHECK the system is working properly. If the fuse blows again, FIND and REPAIR the short to «mass», using wiring diagrams. |

|

|

I2: FUSE VOLTAGE TEST F36 |

|

|

1 Connect Fuse F36 (CJB). |

|

|

2 Check the voltage in the electrical circuit between fuse F36 (7,5 A) And "weight". |

|

|

• Is battery voltage being recorded? |

|

|

→ Yes |

|

|

Go to I3 |

|

|

→ No |

|

|

RESTORE power to fuse F36 using the wiring diagrams. CHECK the system is working properly. |

|

|

I3: F45 FUSE CHECK |

|

|

1 CHECK Fuse F45 (CJB). |

|

|

• Is the fuse good? |

|

|

→ Yes |

|

|

Go to I4 |

|

|

→ No |

|

|

REPLACE fuse F45 (7,5 A). CHECK the system is working properly. If the fuse blows again, FIND and REPAIR the short to «mass», using wiring diagrams. |

|

|

I4: FUSE VOLTAGE CHECK F45 |

|

|

1 Connect Fuse F45 (CJB). |

|

|

2 Drive the ON position. |

|

|

3 Check the voltage in the electrical circuit between fuse F45 (7,5 A) And "weight". |

|

|

• Is battery voltage being recorded? |

|

|

→ Yes |

|

|

Go to I5 |

|

|

→ No |

|

|

RESTORE power to fuse F45 using the wiring diagrams. CHECK the system is working properly. |

|

|

I5: VOLTAGE CHECK IN THE EATC MODULE |

|

|

1 Enter the OFF position. |

|

|

2 Disconnect the C380 of the EATC module. |

|

|

3 Measure the voltage between pin 8 of connector C380 of the EATC module, circuit 29-FA13 (orange), on the wiring harness side, and «weight». |

|

• Is battery voltage being recorded? |

|

|

→ Yes |

|

|

Go to I6 |

|

|

→ No |

|

|

LOCATE and REPAIR the open circuit between fuse F36 and the EATC module using the wiring diagrams. CHECK the system is working properly. |

|

|

I6: VOLTAGE TEST IN EATC MODULE |

|

|

1 Drive the ON position. |

|

|

2 Measure the voltage between pin 10 of connector C380 of the EATC module, circuit 15-FA13 (green-red), on the wiring harness side, and «weight». |

|

• Is battery voltage being recorded? |

|

|

→ Yes |

|

|

Go to I7 |

|

|

→ No |

|

|

LOCATE and REPAIR the open circuit between fuse F45 and the EATC module using the wiring diagrams. CHECK the system is working properly. |

|

|

I7: CHECK EATC MODULE GROUND CIRCUIT |

|

|

1 Enter the OFF position. |

|

|

2 Measure the resistance between EATC module connector C380 pin, 12, circuit 91-FA13 (black-orange), on the wiring harness side, and «weight». |

|

• Is the measured resistance less than 2 ohms? |

|

|

→ Yes |

|

|

CHECK and, if necessary, REPLACE the EATC module. CHECK the system is working properly. |

|

|

→ No |

|

|

LOCATE and REPAIR the open circuit between the EATC module and the G41 ground point using the wiring diagrams. CHECK the system is working properly. |

|

PINPOINT TEST J: IMPROPER FUNCTIONING OF THE HEATER FAN (ONLY VEHICLES WITH EATC)

|

STATES |

DETAILS/RESULTS/ACTIONS |

|

J1: F64 FUSE CHECK |

|

|

1 Enter the OFF position. |

|

|

2 CHECK Fuse F64 (BJB). |

|

|

• Is the fuse good? |

|

|

→ Yes |

|

|

Go to J2 |

|

|

→ No |

|

|

REPLACE fuse F64 (40 A). CHECK the system is working properly. If the fuse blows again, FIND and REPAIR the short to «mass», using wiring diagrams. |

|

|

J2: FUSE VOLTAGE TEST F64 |

|

|

1 Connect F64 fuse (BJB). |

|

|

2 Drive the ON position. |

|

|

3 Check voltage between fuse F64 (40 A) And "weight". |

|

|

• Is battery voltage being recorded? |

|

|

→ Yes |

|

|

Go to J3 |

|

|

→ No |

|

|

RESTORE power to fuse F64 using the wiring diagrams. CHECK the system is working properly. |

|

|

J3: VOLTAGE CHECK IN HEATER FAN MOTOR |

|

|

1 Enter the OFF position. |

|

|

2 Disconnect the C537 heater blower motor. |

|

|

3 Drive the ON position. |

|

|

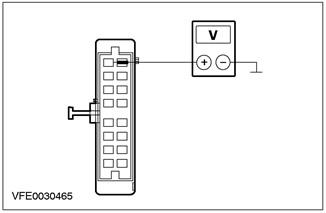

4 Measure the voltage between pin 2 of connector C537 of the heater fan (right-hand drive vehicles: pin 1), electrical circuit 15S-FA18 (green-orange), on the wiring harness side, and «weight». |

|

• Is battery voltage being recorded? |

|

|

→ Yes |

|

|

Go to J4 |

|

|

→ No |

|

|

LOCATE and REPAIR the open circuit between the heater fan motor and fuse F64 using the wiring diagrams. CHECK the system is working properly. |

|

|

J4: HEATER ELECTRIC FAN GROUND CIRCUIT CHECK |

|

|

1 Enter the OFF position. |

|

|

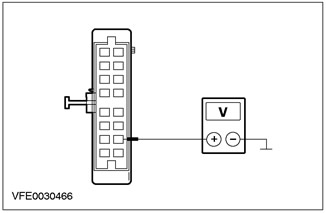

2 Measure the resistance between pin 1 of connector C537 heater fan (right hand drive vehicles: pin 2), electric circuit 31-FA45 (black), on the wiring harness side, and «weight». |

|

• Is the measured resistance less than 2 ohms? |

|

|

→ Yes |

|

|

Go to J5 |

|

|

→ No |

|

|

LOCATE and REPAIR the open circuit between the heater fan motor and ground point G14 using the wiring diagrams. CHECK the system is working properly. |

|

|

J5: CHECKING THE ELECTRICAL CIRCUITS BETWEEN THE HEATER ELECTRIC FAN AND THE EATC MODULE |

|

|

1 Disconnect the C539 of the EATC module. |

|

|

2 Measure the resistance between pin 3 of connector C537 of the heater fan (right-hand drive vehicles: pin 5), electrical circuit 9-FA45 (brown-blue), on the wiring harness side, and pin 26 of connector C539 of the EATC module, circuit 9-FA45 (brown-blue), from the wiring harness side. |

|

3 Measure the resistance between pin 6 of connector C537 of the heater fan (right-hand drive vehicles: pin 4), electrical circuit 49S-FA45 (white-blue), on the wiring harness side, and pin 25 of connector C539 of the EATC module, circuit 49S-FA45 (white-blue), from the wiring harness side. |

|

• Is the measured resistance less than 2 ohms in both cases? |

|

|

→ Yes |

|

|

Go to J6 |

|

|

→ No |

|

|

LOCATE and REPAIR open circuit 9-FA45 (brown-blue) or 49S-FA45 (white-blue) between the heater fan motor and the EATC module, using the wiring diagrams. CHECK the system is working properly. |

|

|

J6: CHECK THE ELECTRICAL CIRCUIT BETWEEN THE EATC MODULE AND THE HEATER ELECTRIC FAN FOR A SHORT TO + OF THE BATTERY |

|

|

1 Drive the ON position. |

|

|

2 Measure the voltage between pin 26 of connector C539 of the EATC module, circuit 9-FA45 (brown-blue), on the wiring harness side, and «weight». |

|

3 Measure the voltage between pin 25 of connector C539 of the EATC module, circuit 49S-FA45 (white-blue), on the wiring harness side, and «weight». |

|

|

• Is voltage recorded for each of these measurements? |

|

|

→ Yes |

|

|

Go to J7 |

|

|

→ No |

|

|

LOCATE and REPAIR short to + battery in circuit 9-FA45 (brown-blue) or 49S-FA45 (white-blue) between the heater fan motor and the EATC module, using the wiring diagrams. CHECK the system is working properly. |

|

|

J7: CHECK THE ELECTRICAL CIRCUIT BETWEEN THE EATC MODULE AND THE HEATER ELECTRIC FAN FOR A SHORT TO « MASS » |

|

|

1 Enter the OFF position. |

|

|

2 Measure the resistance between pin 26 of connector C539 of the EATC module, circuit 9-FA45 (brown-blue), on the wiring harness side, and «weight». |

|

3 Measure the resistance between 25 pin C539 of the EATC module connector, circuit 49S-FA45 (white-blue), on the wiring harness side, and «weight». |

|

|

• Is the measured resistance greater than 10 kΩ in both cases? |

|

|

→ Yes |

|

|

Go to J8 |

|

|

→ No |

|

|

FIND and REPAIR short circuit «mass» in the electrical circuit 9-FA45 (brown-blue) or 49S-FA45 (white-blue) between the heater fan motor and the EATC module, using the wiring diagrams. CHECK the system is working properly. |

|

|

J8: CHECK THE HEATER ELECTRIC FAN |

|

|

1 Connect C537 heater fan motor. |

|

|

2 Drive the ON position. |

|

|

• Is the heater fan operating at approximately half power? |

|

|

→ Yes |

|

|

CHECK and, if necessary, REPLACE the EATC module. CHECK the system is working properly. |

|

|

→ No |

|

|

REPLACE heater fan. CHECK the system is working properly. |

|

PINPOINT TEST K: INCORRECT FUNCTIONING OF THE AIR RECIRCULATION DAMPER (ONLY VEHICLES WITH EATC)

|

STATES |

DETAILS/RESULTS/ACTIONS |

|

NOTE: The air recirculation damper is driven by a DC motor. After pressing the air recirculation button, this DC motor is turned on by the EATC control module for a maximum of 7 seconds. The air recirculation damper is opened and closed by changing the polarity of the applied voltage. |

|

|

NOTE: If the radio button is pressed «anti-fogging / anti-icing windows», you cannot turn on the air recirculation mode. |

|

|

K1: VOLTAGE TEST OF AIR RECIRCULATION POSITIONING MOTOR CIRCUIT |

|

|

1 Enter the OFF position. |

|

|

2 Disconnect the C538 air recirculation damper position motor. |

|

|

3 Drive the ON position. |

|

|

4 Measure the voltage between pins 2 and 4 of connector C538 of the air recirculation damper positioning motor, wiring harness side. |

|

|

5 During the measurement, press the air recirculation button several times. |

|

|

• Is a voltage of about 11 V detected with reverse polarity? |

|

|

→ Yes |

|

|

CHECK the air recirculation damper for freedom of movement and proper operation. If the air recirculation damper is mechanically OK, REPLACE the air recirculation damper positioning motor. CHECK the system is working properly. |

|

|

→ No |

|

|

Go to K2 |

|

|

K2: CHECK THE ELECTRICAL CIRCUIT BETWEEN THE AIR RECIRCULATION DAMPER POSITIONING MOTOR AND THE EATC MODULE FOR AN OPEN |

|

|

1 Enter the OFF position. |

|

|

2 Disconnect the C539 of the EATC module. |

|

|

3 Measure the resistance between pin 2 of connector C538 of the air recirculation damper position motor, circuit 33-FA76 (yellow-blue) (right hand drive vehicles: electrical circuit 32-FA76 (white-blue)), on the wiring harness side, and pin 17 of connector C539 of the EATC 17 module, circuit 33-FA76 (yellow-blue), from the wiring harness side. |

|

|

4 Measure the resistance between pin 4 of connector C538 of the air recirculation damper position motor, circuit 32-FA76 (white-blue) (right hand drive vehicles: electrical circuit 33-FA76 (yellow-blue)), on the wiring harness side, and pin 1 of connector C539 of EATC module 1, circuit 32-FA76 (white-blue), from the wiring harness side. |

|

|

• Is the measured resistance less than 2 ohms in both cases? |

|

|

→ Yes |

|

|

Go to K3 |

|

|

→ No |

|

|

LOCATE and REPAIR open circuit 32-FA76 (white-blue) or 33-FA76 (yellow-blue) between the air recirculation damper position motor and the EATC module using the wiring diagrams. CHECK the system is working properly. |

|

|

K3: CHECK THE ELECTRICAL CIRCUIT BETWEEN THE AIR RECIRCULATION DAMPER POSITIONING MOTOR AND THE EATC MODULE FOR A SHORT TO + OF THE BATTERY |

|

|

1 Drive the ON position. |

|

|

2 Measure the voltage between pin 17 of connector C539 of the EATC module, circuit 33-FA76 (yellow-blue), on the wiring harness side, and «weight». |

|

3 Measure the voltage between pin 1 of connector C539 of the EATC module, circuit 32-FA76 (white-blue), on the wiring harness side, and «weight». |

|

|

• Is voltage recorded for each of these measurements? |

|

|

→ Yes |

|

|

LOCATE and REPAIR short to battery in circuit 32-FA76 (white-blue) or 33-FA76 (yellow-blue) between the air recirculation damper position motor and the EATC module using the wiring diagrams. CHECK the system is working properly. |

|

|

→ No |

|

|

Go to K4 |

|

|

K4: CHECK THE ELECTRICAL CIRCUIT BETWEEN THE AIR RECIRCULATION DAMPER POSITIONING MOTOR AND THE EATC MODULE FOR A SHORT TO « MASS » |

|

|

1 Enter the OFF position. |

|

|

2 Measure the resistance between pin 17 of connector C539 of the EATC module, circuit 33-FA76 (yellow-blue), on the wiring harness side, and «weight». |

|

3 Measure the resistance between pin 1 of connector C539 of the EATC module, circuit 32-FA76 (white-blue), on the wiring harness side, and «weight». |

|

|

• Is the measured resistance greater than 10 kΩ in both cases? |

|

|

→ Yes |

|

|

CHECK and, if necessary, REPLACE the EATC module. CHECK the system is working properly. |

|

|

→ No |

|

|

FIND and REPAIR short circuit «mass» in the electrical circuit 32-FA76 (white-blue) or 33-FA76 (yellow-blue) between the air recirculation damper position motor and the EATC module using the wiring diagrams. CHECK the system is working properly. |

|

PINPOINT TEST L: ANTI-ICE SHUTTER MALFUNCTIONING (ONLY VEHICLES WITH EATC)

|

STATES |

DETAILS/RESULTS/ACTIONS |

|

L1: CHECK CIRCUIT BETWEEN ANTI-ICE POSITION MOTOR AND EATC MODULE FOR OPEN |

|

|

1 Enter the OFF position. |

|

|

2 Disconnect the C539 of the EATC module. |

|

|

3 Disconnect the C532 defrost position motor. |

|

|

4 Measure the resistance between pin 2 of connector C532 of the defrost position motor, circuit 15S-FB14 (green-blue), on the wiring harness side, and pin 10 of connector C539 of the EATC module, circuit 15S-FB1 (green-yellow), from the wiring harness side. |

|

5 Measure the resistance between pin 1 of connector C532, defrost position motor, circuit 31S-FB15 (black-orange), on the wiring harness side, and pin 11 of connector C539 of the EATC module, circuit 31S-FB15 (black and blue), from the wiring harness side. |

|

6 Measure the resistance between pin 3 of connector C532 of the defrost position motor, circuit 31S-FB16 (black and green), on the wiring harness side, and pin 12 of connector C539 of the EATC module, circuit 31S-FB16 (black and green), from the wiring harness side. |

|

7 Measure the resistance between pin 4 of connector C532 of the defrost position motor, circuit 31S-FB17 (black and red), on the wiring harness side, and pin 27 of connector C539 of the EATC module, circuit 31S-FB17 (black and red), from the wiring harness side. |

|

8 Measure the resistance between pin 6 of connector C532 of the defrost position motor, circuit 31S-FB18 (black and white), on the wiring harness side, and pin 28 of connector C539 of the EATC module, circuit 31S-FB18 (black and white), from the wiring harness side. |

|

• Is the measured resistance less than 2 ohms in all cases? |

|

|

→ Yes |

|

|

Go to L2 |

|

|

→ No |

|

|

LOCATE and REPAIR the open circuit in question between the defrost position motor and the EATC module using the wiring diagrams. CHECK the system is working properly. |

|

|

L2: CHECK THE ELECTRICAL CIRCUIT BETWEEN THE ANTI-ICE SHUTTER POSITIONING MOTOR AND THE EATC MODULE FOR A SHORT TO + OF THE BATTERY |

|

|

1 Drive the ON position. |

|

|

2 Measure the voltage between pin 2 of connector C532 of the defrost position motor, circuit 15S-FB14 (green-blue), on the wiring harness side, and «weight». |

|

3 Measure the voltage between pin 1 of connector C532 of the defrost position motor, circuit 31S-FB15 (black-orange), on the wiring harness side, and «weight». |

|

4 Measure the voltage between pin 3 of connector C532 of the defrost position motor, circuit 31S-FB16 (black and green), on the wiring harness side, and «weight». |

|

5 Measure the voltage between pin 4 of connector C532 of the defrost position motor, circuit 31S-FB17 (black and red), on the wiring harness side, and «weight». |

|

6 Measure the voltage between pin 6 of connector C532 of the defrost position motor, circuit 31S-FB18 (black and white), on the wiring harness side, and «weight». |

|

• Is voltage recorded for each of these measurements? |

|

|

→ Yes |

|

|

LOCATE and REPAIR short to battery on the circuit in question between the anti-icing flap position motor and the EATC module using the wiring diagrams. CHECK the system is working properly. |

|

|

→ No |

|

|

Go to L3 |

|

|

L3: CHECK THE ELECTRICAL CIRCUIT BETWEEN THE ANTI-ICE POSITIONING MOTOR AND THE EATC MODULE FOR A SHORT TO « MASS » |

|

|

1 Enter the OFF position. |

|

|

2 Measure the resistance between pin 2 of connector C532 of the defrost position motor, circuit 15S-FB14 (green-blue), on the wiring harness side, and «weight». |

|

3 Measure the resistance between pin 1 of connector C532, defrost position motor, circuit 31S-FB15 (black-orange), on the wiring harness side, and «weight». |

|

4 Measure the resistance between pin 3 of connector C532 of the defrost position motor, circuit 31S-FB16 (black and green), on the wiring harness side, and «weight». |

|

5 Measure the resistance between pin 4 of connector C532 of the defrost position motor, circuit 31S-FB17 (black and red), on the wiring harness side, and «weight». |

|

6 Measure the resistance between pin 6 of connector C532 of the defrost position motor, circuit 31S-FB18 (black and white), on the wiring harness side, and «weight». |

|

• Is the measured resistance greater than 10 kΩ in all cases? |

|

|

→ Yes |

|

|

CHECK the anti-freeze damper for freedom of movement and proper operation. If the de-icing flap is mechanically OK, REPLACE the de-icing flap positioning motor. CHECK the system is working properly. |

|

|

→ No |

|

|

FIND and REPAIR short circuit «mass» in the considered electrical circuit between the anti-icing flap positioning motor and the EATC module, using the wiring diagrams. CHECK the system is working properly. |

|

PINPOINT TEST M: INCORRECT FUNCTIONING OF THE AIR DISTRIBUTION DAMPER (ONLY VEHICLES WITH EATC)

|

STATES |

DETAILS/RESULTS/ACTIONS |

|

M1: INSTRUMENT PANEL SHUTTER POSITIONING/FOOTBET POSITIONING MOTOR AND EATC MODULE CHECK FOR OPEN CIRCUIT |

|

|

1 Enter the OFF position. |

|

|

2 Disconnect the C539 of the EATC module. |

|

|

3 Disconnect the C533 Dashboard/Footwell Positioning Motor. |

|

|

4 Measure the resistance between C533 pin 2 of the instrument/footwell flap position motor, circuit 15S-FB19 (green-yellow), on the wiring harness side, and pin 10 of connector C539 of the EATC module, circuit 15S-FB1 (green-yellow), from the wiring harness side. |

|

5 Measure the resistance between C533 pin 1 of the instrument/footwell flap positioning motor, circuit 31S-FB20 (black and blue), on the wiring harness side, and pin 13 of connector C539 of the EATC module, circuit 31S-FB20 (black and blue), from the wiring harness side. |

|

6 Measure the resistance between C533 pin 3 of the dash/footwell flap positioning motor, circuit 31S-FB21 (black-orange), on the wiring harness side, and pin 14 of connector C539 of the EATC module, circuit 31S-FB21 (black-orange), from the wiring harness side. |

|

7 Measure the resistance between C533 pin 4 of the instrument panel/footwell flap positioning motor, circuit 31S-FB22 (black and green), on the wiring harness side, and pin 29 of connector C539 of the EATC module, circuit 31S-FB22 (black and green), from the wiring harness side. |

|

8 Measure the resistance between pin 6 of connector C533 of the dash/footwell flap positioning motor, circuit 31S-FB23 (black and red), on the wiring harness side, and pin 30 of connector C539 of the EATC module, circuit 31S-FB23 (black and red), from the wiring harness side. |

|

• Is the measured resistance less than 2 ohms in all cases? |

|

|

→ Yes |

|

|

Navigate to M2 |

|

|

→ No |

|

|

LOCATE and REPAIR the open in the circuit in question between the dash/footwell flap position motor and the EATC module using the wiring diagrams. CHECK the system is working properly. |

|

|

M2: CHECK THE ELECTRICAL CIRCUITS BETWEEN INSTRUMENT PANEL SHUTTER POSITIONING/FOOTBET POSITIONING MOTOR AND THE EATC MODULE FOR A SHORT TO BATTERY |

|

|

1 Drive the ON position. |

|

|

2 Measure the voltage between pin 2 of connector C533 of the instrument/footwell flap position motor, circuit 15S-FB19 (green-yellow), on the wiring harness side, and «weight». |

|

3 Measure the voltage between C533 pin 1 of the dash/footwell flap positioning motor, circuit 31S-FB20 (black and blue), on the wiring harness side, and «weight». |

|

4 Measure the voltage between pin 3 of connector C533 of the instrument/footwell flap positioning motor, circuit 31S-FB21 (black-orange), on the wiring harness side, and «weight». |

|

5 Measure the voltage between pin 4 of connector C533 of the dash/footwell flap positioning motor, circuit 31S-FB22 (black and green), on the wiring harness side, and «weight». |

|

6 Measure the voltage between pin 6 of connector C533 of the dash/footwell flap positioning motor, circuit 31S-FB23 (black and red), on the wiring harness side, and «weight». |

|

• Is voltage recorded for each of these measurements? |

|

|

→ Yes |

|

|

LOCATE and REPAIR short to battery on the circuit in question between the dash/footwell flap position motor and the EATC module using the wiring diagrams. CHECK the system is working properly. |

|

|

→ No |

|

|

Go to M3 |

|

|

M3: CHECK THE ELECTRICAL CIRCUITS BETWEEN INSTRUMENT PANEL SHUTTER POSITIONING/FOOTBET POSITIONING MOTOR AND THE EATC MODULE FOR A SHORT TO « MASS » |

|

|

1 Enter the OFF position. |

|

|

2 Measure the resistance between C533 pin 2 of the instrument/footwell flap positioning motor, circuit 15S-FB19 (green-yellow), on the wiring harness side, and «weight». |

|

3 Measure the resistance between C533 pin 1 of the dash/footwell flap positioning motor, circuit 31S-FB20 (black and blue), on the wiring harness side, and «weight». |

|

4 Measure the resistance between C533 pin 3 of the instrument/footwell flap positioning motor, circuit 31S-FB21 (black-orange), on the wiring harness side, and «weight». |

|

5 Measure the resistance between pin 4 of connector C533 of the dash/footwell flap positioning motor, circuit 31S-FB22 (black and green), on the wiring harness side, and «weight». |

|

6 Measure the resistance between pin 6 of connector C533 of the dash/footwell flap positioning motor, circuit 31S-FB23 (black and red), on the wiring harness side, and «weight». |

|

• Is the measured resistance greater than 10 kΩ in all cases? |

|

|

→ Yes |

|

|

CHECK the distribution flap for freedom of movement and correct operation. If the air distribution flap is mechanically OK, REPLACE the instrument panel/footwell flap positioning motor. CHECK the system is working properly. |

|

|

→ No |

|

|

FIND and REPAIR short circuit «mass» in the electrical circuit in question between the instrument panel flap/footwell positioning motor and the EATC module, using the wiring diagrams. CHECK the system is working properly. |

|

PINPOINT TEST N: INCORRECT FUNCTIONING OF THE AIR TEMPERATURE SHUTTER (ONLY VEHICLES WITH EATC)

|

STATES |

DETAILS/RESULTS/ACTIONS |

|

N1: CHECK THE ELECTRICAL CIRCUIT BETWEEN THE AIR TEMP POSITIONING MOTOR AND THE EATC MODULE FOR AN OPEN |

|

|

1 Enter the OFF position. |

|

|

2 Disconnect the C539 of the EATC module. |

|

|

3 Disconnect the C534 air temperature damper position motor. |

|

|

4 Measure the resistance between pin 2 of connector C534 of air temperature damper position motor, circuit 15S-FB9 (green-red), on the wiring harness side, and pin 10 of connector C539 of the EATC module, circuit 15S-FB1 (green-yellow), from the wiring harness side. |

|

5 Measure the resistance between C534 pin 1 of the air temperature damper position motor, circuit 31S-FB10 (black and green), on the wiring harness side, and pin 15 of connector C539 of the EATC module, circuit 31S-FB10 (black and green), from the wiring harness side. |

|

6 Measure the resistance between pin 3 of connector C534 of the air temperature damper position motor, circuit 31S-FB11 (BK/RD), on the wiring harness side, and pin 16 of connector C539 of the EATC module, circuit 31S-FB11 (black and red), from the wiring harness side. |

|

7 Measure the resistance between pin 4 of connector C534 of the air temperature damper position motor, circuit 31S-FB12 (black and white), on the wiring harness side, and pin 31 of connector C539 of the EATC module, circuit 31S-FB12 (black and white), from the wiring harness side. |

|

8 Measure the resistance between pin 6 of connector C534 of air temperature damper position motor, circuit 31S-FB13 (black and yellow), on the wiring harness side, and pin 32 of connector C539 of the EATC module, circuit 31S-FB13 (black and yellow), from the wiring harness side. |

|

• Is the measured resistance less than 2 ohms in all cases? |

|

|

→ Yes |

|

|

Go to N2 |

|

|

→ No |

|

|

LOCATE and REPAIR the open circuit in question between the air temperature damper position motor and the EATC module using the wiring diagrams. CHECK the system is working properly. |

|

|

N2: CHECK THE ELECTRICAL CIRCUIT BETWEEN THE AIR TEMPERATURE POSITIONING MOTOR AND THE EATC MODULE FOR A SHORT TO + OF THE BATTERY |

|

|

1 Drive the ON position. |

|

|

2 Measure the voltage between pin 2 of connector C534 of the air temperature damper position motor, circuit 15S-FB9 (green-red), on the wiring harness side, and «weight». |

|

3 Measure the voltage between C534 pin 1 of the air temperature damper position motor, circuit 31S-FB10 (black and green), on the wiring harness side, and «weight». |

|

4 Measure the voltage between pin 3 of connector C534 of the air temperature damper position motor, circuit 31S-FB11 (black and red), on the wiring harness side, and «weight». |

|

5 Measure the voltage between pin 4 of connector C534 of the air temperature damper position motor, circuit 31S-FB12 (black and white), on the wiring harness side, and «weight». |

|

6 Measure the voltage between pin 6 of connector C534 of air temperature damper position motor, circuit 31S-FB13 (black and yellow), on the wiring harness side, and «weight». |

|

• Is voltage recorded for each of these measurements? |

|

|

→ Yes |

|

|

LOCATE and REPAIR short to battery on the circuit in question between the air temperature damper position motor and the EATC module using the wiring diagrams. CHECK the system is working properly. |

|

|

→ No |

|

|

Go to N3 |

|

|

N3: CHECK THE ELECTRICAL CIRCUIT BETWEEN THE AIR TEMPERATURE POSITIONING MOTOR AND THE EATC MODULE FOR A SHORT TO « MASS » |

|

|

1 Enter the OFF position. |

|

|

2 Measure the resistance between pin 2 of connector C534 of the air temperature damper position motor, circuit 15S-FB9 (green-red), on the wiring harness side, and «weight». |

|

3 Measure the resistance between pin 1 of connector C534 of air temperature damper position motor, circuit 31S-FB10 (black and green), on the wiring harness side, and «weight». |

|

4 Measure the resistance between pin 3 of connector C534 of the air temperature damper position motor, circuit 31S-FB11 (black and red), on the wiring harness side, and «weight». |

|

5 Measure the resistance between pin 4 of connector C534 of the air temperature damper position motor, circuit 31S-FB12 (black and white), on the wiring harness side, and «weight». |

|

6 Measure the resistance between pin 6 of connector C534 of air temperature damper position motor, circuit 31S-FB13 (black and yellow), on the wiring harness side, and «weight». |

|

• Is the measured resistance greater than 10 kΩ in all cases? |

|

|

→ Yes |

|

|

CHECK the air temperature damper for freedom of movement and correct operation. If the air temperature damper is mechanically OK, REPLACE the air temperature damper positioning motor. CHECK the system is working properly. |

|

|

→ No |

|

|

FIND and REPAIR short circuit «mass» in the considered electrical circuit between the air temperature damper positioning motor and the EATC module, using the wiring diagrams. CHECK the system is working properly. |

|

PINPOINT TEST O: FAULT IN THE AIR TEMPERATURE SENSOR OUTLET OF THE FOOTBALL (ONLY VEHICLES WITH EATC)

|

STATES |

DETAILS/RESULTS/ACTIONS |

|

O1: CHECK THE ELECTRICAL CIRCUIT BETWEEN THE FOOTBALL OUTLET AIR TEMPERATURE SENSOR AND THE EATC MODULE FOR OPEN |

|

|

1 Enter the OFF position. |

|

|

2 Disconnect the C539 of the EATC module. |

|

|

3 Disconnect the C536 footwell outlet air temperature sensor. |

|

|

4 Measure the resistance between pin 1 of connector C536, footwell outlet air temperature sensor, circuit 8-FA51 (white and black), on the wiring harness side, and pin 8 of connector C539 of the EATC module, circuit 8-FA51 (white and black), from the wiring harness side. |

|

5 Measure the resistance between pin 2 of connector C536, footwell outlet air temperature sensor, circuit 9-FA51 (brown yellow), on the wiring harness side, and pin 7 of connector C539 of the EATC module, circuit 9-FA3 (brown red), from the wiring harness side. |

|

• Is the measured resistance less than 2 ohms in both cases? |

|

|

→ Yes |

|

|

Go to O2 |

|

|

→ No |

|

|

LOCATE and REPAIR the open circuit in question between the footwell outlet air temperature sensor and the EATC module using the wiring diagrams. CHECK the system is working properly. |

|

|

O2: CHECK THE ELECTRICAL CIRCUIT BETWEEN THE FOOTBALL OUTLET AIR TEMPERATURE SENSOR AND THE EATC MODULE FOR A SHORT TO + OF THE BATTERY |

|

|

1 Drive the ON position. |

|

|

2 Measure the voltage between pin 1 of connector C536, footwell outlet air temperature sensor, circuit 8-FA51 (white and black), on the wiring harness side, and «weight». |

|

3 Measure the voltage between pin 2 of connector C536, footwell outlet air temperature sensor, circuit 9-FA51 (brown yellow), on the wiring harness side, and «weight». |

|

|

• Is voltage recorded for each of these measurements? |

|

|

→ Yes |

|

|

LOCATE and REPAIR short to battery on the circuit in question between the footwell outlet air temperature sensor and the EATC module using the wiring diagrams. CHECK the system is working properly. |

|

|

→ No |

|

|

Go to O3 |

|

|

O3: CHECK THE ELECTRICAL CIRCUIT BETWEEN THE FEET OUTLET AIR TEMPERATURE SENSOR AND THE EATC MODULE FOR A SHORT TO « MASS » |

|

|

1 Enter the OFF position. |

|

|

2 Measure the resistance between pin 1 of connector C536, footwell outlet air temperature sensor, circuit 8-FA51 (white and black), on the wiring harness side, and «weight». |

|

3 Measure the resistance between pin 2 of connector C536, footwell outlet air temperature sensor, circuit 9-FA51 (brown yellow), on the wiring harness side, and «weight». |

|

|

• Is the measured resistance greater than 10 kΩ in both cases? |

|

|

→ Yes |

|

|

REPLACE the footwell outlet air temperature sensor. CHECK the system is working properly. |

|

|

→ No |

|

|

FIND and REPAIR short circuit «mass» in the electrical circuit in question between the footwell outlet air temperature sensor and the EATC module, using the wiring diagrams. CHECK the system is working properly. |

|

PINPOINT TEST P: FAULT IN INSTRUMENT PANEL OUTLET AIR TEMPERATURE SENSOR CIRCUIT (ONLY VEHICLES WITH EATC)

|

STATES |

DETAILS/RESULTS/ACTIONS |

|

P1: CHECK THE ELECTRICAL CIRCUIT BETWEEN THE INSTRUMENT PANEL OUTLET AIR TEMPERATURE SENSOR AND THE EATC MODULE FOR OPEN |

|

|

1 Enter the OFF position. |

|

|

2 Disconnect the C539 of the EATC module. |

|

|

3 Disconnect the C535 downstream air temperature sensor. |

|

|

4 Measure the resistance between pin 1 of connector C535, instrument panel outlet air temperature sensor, circuit 8-FA47 (white-green), on the wiring harness side, and pin 9 of connector C539 of the EATC module, circuit 8-FA47 (white-green), from the wiring harness side. |

|

5 Measure the resistance between pin 2 of connector C535, instrument panel outlet air temperature sensor, circuit 9-FA47 (brown-green), on the wiring harness side, and pin 7 of connector C539 of the EATC module, circuit 9-FA3 (brown red), from the wiring harness side. |

|

• Is the measured resistance less than 2 ohms in both cases? |

|

|

→ Yes |

|

|

Go to P2 |

|

|

→ No |

|

|

LOCATE and REPAIR the open circuit in question between the instrument panel outlet air temperature sensor and the EATC module using the wiring diagrams. CHECK the system is working properly. |

|

|

P2: CHECK THE ELECTRICAL CIRCUIT BETWEEN THE INSTRUMENT PANEL OUTLET AIR TEMPERATURE SENSOR AND THE EATC MODULE FOR A SHORT TO BATTERY |

|

|

1 Drive the ON position. |

|

|

2 Measure the voltage between pin 1 of connector C535, instrument panel outlet air temperature sensor, circuit 8-FA47 (white-green), on the wiring harness side, and «weight». |

|

3 Measure the voltage between pin 2 of connector C535, instrument panel outlet air temperature sensor circuit 9-FA47 (brown-green), on the wiring harness side, and «weight». |

|

|

• Is voltage recorded for each of these measurements? |

|

|

→ Yes |

|

|

LOCATE and REPAIR short to battery on the circuit in question between the instrument panel outlet air temperature sensor and the EATC module using the wiring diagrams. CHECK the system is working properly. |

|

|

→ No |

|

|

Go to P3 |

|

|

P3: CHECK THE ELECTRICAL CIRCUIT BETWEEN THE INSTRUMENT PANEL OUTLET AIR TEMPERATURE SENSOR AND THE EATC MODULE FOR A SHORT TO « MASS » |

|

|

1 Enter the OFF position. |

|

|

2 Measure the resistance between pin 1 of connector C535, instrument panel outlet air temperature sensor, circuit 8-FA47 (white-green), on the wiring harness side, and «weight». |

|

3 Measure the resistance between pin 2 of connector C535, instrument panel outlet air temperature sensor, circuit 9-FA47 (brown-green), on the wiring harness side, and «weight». |

|

|

• Is the measured resistance greater than 10 kΩ in both cases? |

|

|

→ Yes |

|

|

REPLACE the instrument panel outlet air temperature sensor. CHECK the system is working properly. |

|

|

→ No |

|

|

FIND and REPAIR short circuit «mass» in the electrical circuit in question between the instrument panel outlet air temperature sensor and the EATC module, using the wiring diagrams. CHECK the system is working properly. |

|

PINPOINT TEST Q: FAULT IN SOLAR SENSOR CIRCUIT (ONLY VEHICLES WITH EATC)

|

STATES |

DETAILS/RESULTS/ACTIONS |

|

Q1: CHECK THE ELECTRICAL CIRCUIT BETWEEN SOLAR SENSOR AND EATC MODULE FOR OPEN |

|

|

1 Enter the OFF position. |

|

|

2 Disconnect the C539 of the EATC module. |

|

|

3 Disconnect the trip computer module C467. |

|

|

4 Disconnect the C531 solar sensor. |

|

|

5 Measure the resistance between pin 1 of connector C531 of the sun sensor, circuit 8-FA53 (white-blue), on the wiring harness side, and pin 24 of connector C539 of the EATC module, circuit 8-FA53 (white-blue), from the wiring harness side. |

|