- Equal velocity joints are installed at both ends of the front driving semi-axes, which ensure smooth running.

- Tripod joints are installed on the gearbox side ("tripods") (consisting of a tripod element, work rollers and a hinge body).

- The wheel-side joints are ball joints (they include a star-shaped ball cage, a cage and an outer race).

- Left "tripod" is fixed on the differential with a split locking ring.

- intermediate shaft (Right side) mounted on the differential by means of an intermediate support of the intermediate shaft.

- Frame "tripod" the right front drive axle and the intermediate shaft are installed as a single element.

- CV joints on the side of the wheels are attached to the wheel hubs.

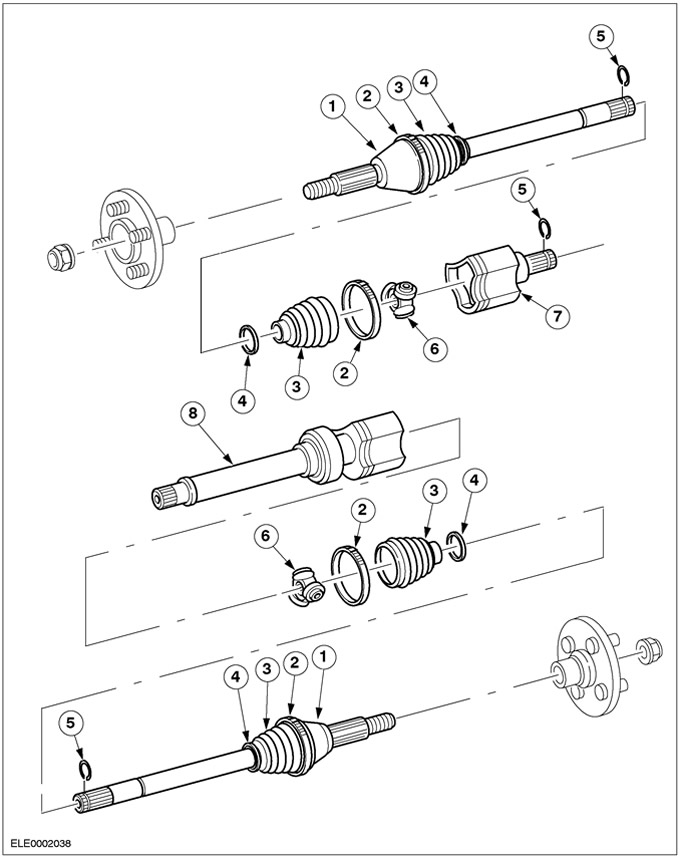

Element-by-element drawing of the front drive axle

| Pos. | Spare Part No | Name |

| 1 | - | Fixed ball joint with front drive shaft |

| 2 | - | Case clamp (big) |

| 3 | - | Case |

| 4 | - | Case clamp (small) |

| 5 | - | CV joint lock ring on the gearbox side |

| 6 | - | star clip "tripod" with rollers of equal angular speeds |

| 7 | - | Hinge housing |

| 8 | - | Intermediate shaft with intermediate support |

The principle of operation of the front drive axles

- The front drive shafts transmit engine torque to the wheels.

- To allow vertical movement of the wheels and the engine, the front drive axles can be operated at different lengths and at different angles.

- Tripod joints ("tripods") provide a change in the length of the semi-axis during axial movements.

Rules for handling the front drive axle shafts

NOTE: Do not apply tensile force to the tripod joints.

When removing / installing and assembling / disassembling the front drive axle shafts, be especially careful. Observe the following rules:

- The inner tripod joint must not be deflected more than 18°.

- Check polished surfaces and splines for damage.

- Do not allow covers to come into contact with sharp edges, a warm engine and exhaust system components.

- Do not allow the front drive axle to fall as this may cause internal damage to the boots without causing any visible external damage.

- Do not use the front drive axles as an alignment aid when installing other items. The front drive axles must always be freely suspended.

- The tripod joint may be damaged by impacts from outside the joint body.

Front wheel balancing

CAUTION: Using a portable wheel balancer with the vehicle fully off the ground will damage the tripod pivots and boots as the pivot swings too far and overheats.

To use the portable balancer, place a rolling jack under the suspension arm opposite the wheel to be balanced. This will prevent excessive deflection of the tripod joint when the vehicle is raised.

If possible, wheels should be removed for balancing and balanced on a stationary wheel balancer.

Vehicle lifting

WARNING: Do not use hinges or front drive axles as vehicle jacking points.

Car towing

WARNING: Do not attach the tow rope to the front drive axle.

Underbody protection and anti-corrosion treatment

NOTE: When applying a protective coating on the bottom and anti-corrosion treatment, the covers must be closed.

The presence of foreign material on the covers can lead to premature aging of the material. Foreign material on the front drive axles can cause imbalance.

Visitor comments