Injector defects can also be found by loosening the high pressure fuel line union nuts while the engine is idling at high engine speeds. If, after releasing the union nut, the crankshaft speed does not change, this indicates a defect in the corresponding injector. The injectors can be checked with a pressure gauge (service station work).

The first signs of injector malfunction are as follows:

- No flashes.

- Knocking in one or more cylinders.

- Engine overheating.

- Loss of engine power.

- Excessively strong black smoke from the exhaust.

- High fuel consumption.

Withdrawal

Disconnect ground wire (-) battery.

Caution: Disconnecting the battery will erase the contents of the electronic memories, such as engine trouble codes or radio codes. Before switching off, also read the instructions in chapter "Removing and installing the battery".

Clean the high pressure fuel lines with a cleaning agent or diesel fuel.

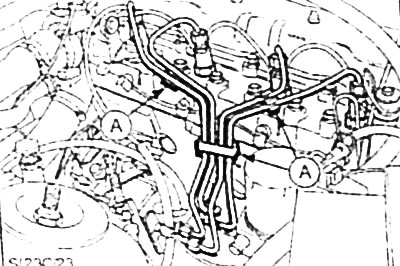

Remove the high-pressure fuel lines as a whole set, for which the union nuts at the high-pressure fuel pump and injectors are loosened with an open ring wrench. To protect the joints from dirt, close the caps.

Attention: Do not change the shape of the pipe bends. A - high pressure fuel line holders.

Disconnect fuel return lines from injectors. To protect the joints from dirt, close the caps.

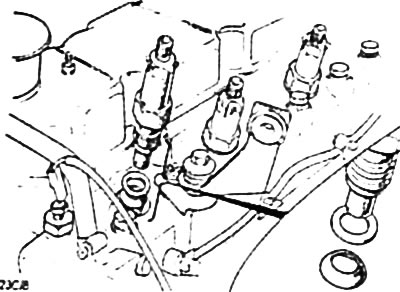

Unscrew the nozzles using a standard socket sprocket, eg HAZET 4555, and install in the same order in which they were installed. Remove the copper O-rings and thermal compensating washers from the holes for the injectors in the cylinder head.

Attention: For models from 9/93 on the injector of cylinder 1 (from the injection pump side) has an electrical connector (for needle lift sensor). Disconnect the electrical cable and unscrew the injector with an asterisk. If necessary, pre-cut the sprocket for the wire. Insert the wire into the end sprocket.

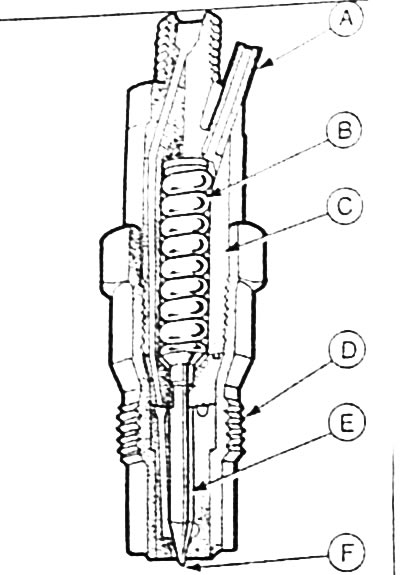

A - fuel outlet

B - pressure spring

C - nozzle body

D - plinth

E - spray needle

F - spray needle pin

Clamp the nozzle base in a vice equipped with soft metal jaws. Disassemble the nozzle.

Check the needle and needle seat of the atomizer for wear, roughness and damage. Use a wooden spatula to clean the nozzle spray from carbon deposits.

Attention. Never clean the atomizer or needle with wire, file or emery. The individual parts of the injectors are not interchangeable.

The atomizer needle must slide in the atomizer body under its own weight. She must move freely.

Installation

Insert 4 new thermal compensation washers, and then 4 new copper sealing rings, with the convex side up, into the nozzle holes in the cylinder head.

Insert the injectors and tighten to 90 Nm, for models with 9/93 to 70 Nm.

Attention: Tightening the base with a higher torque may cause the nozzle to be deformed, which will cause the atomizer needle to hang or some other malfunction.

Attach the high pressure fuel lines to the injectors and injection pump and tighten the cap nuts to 25 Nm.

Connect fuel return lines to injectors.

Slightly loosen the union nuts of the high pressure fuel lines on all injectors.

Turn the crankshaft of the engine with the starter until until fuel comes out at the union nuts. Tighten the union nuts of the high pressure fuel lines to the specified torque.

Connect ground wire (-) battery.

If available, set the clock and enter the radio's anti-theft code.

Visitor comments