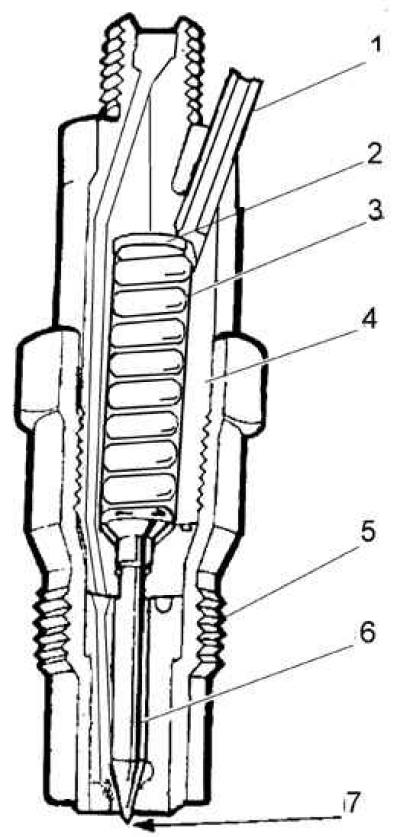

Nozzle

1 – fuel outlet channel; 2 - adjusting washer; 3 - spring; 4 - nozzle body; 5 – atomizer housing; 6 - needle; 7 - nozzle

Check on the engine

To determine a faulty injector, you must:

- make sure that the engine is working and the compression level is the same in all cylinders;

- start the engine and warm it up to operating temperature;

- Loosen the fuel line fitting nut on the injector to be checked. Note if the engine speed has changed. Carry out the same check at fast idle;

- with a working nozzle, there will be a clear decrease in engine speed, accompanied by its uneven operation. If the injector being checked is faulty, the change in engine speed will be insignificant and, if present earlier, an extraneous knock will disappear.

Withdrawal

Attention! Protect the generator from diesel fuel.

1. Disconnect ground wire from battery.

2. Clean the high pressure fuel lines, unscrew the union nuts on the fuel pump and protect them from contamination.

3. Carefully disconnect the injection line connections from the fuel pump.

4. Carefully detach the injection line connections from the injectors.

5. Disconnect fuel return lines from injectors.

6. Unscrew the nozzles and install protective caps on the nozzles.

7. Remove the thermal insulation washers and wipe them off.

8. Clamp the body of the atomizer in a vice with soft jaws, disassemble the nozzle and, using a wooden tool, clean all parts of the nozzle.

9. The nozzle needle under its own weight must slide tightly into the nozzle seat.

Installation

1. Install new thermal insulation washers with the convex side towards the cylinder head.

2. Insert the injectors into the holes in the cylinder head and tighten them to the required torque. It is allowed to use nozzles if, after their disassembly, cleaning and subsequent assembly, they restore their functionality and withstand all tests.

3. Screw the injection pipe connections to the injectors. Make sure that the pipe clamps are (anti-vibration) are in the required places.

4. Screw the injection pipe connections to the fuel pump.

5. Install fuel return lines to injectors.

6. Connect the battery, start the engine and check the connections for leaks (see subsection 3.2.4.3).

Visitor comments