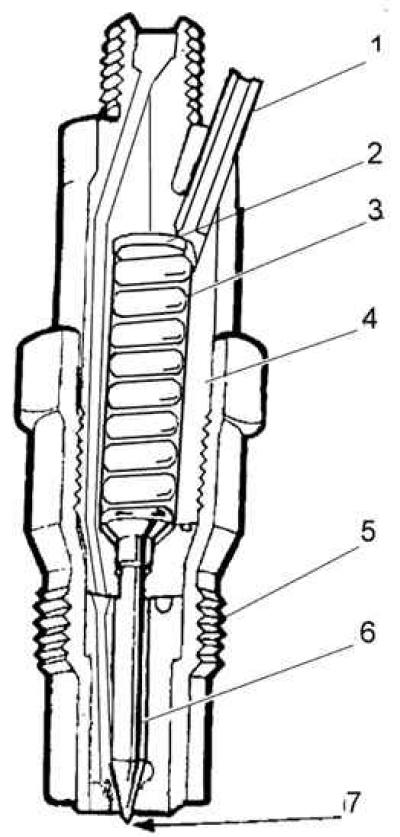

Nozzle

1 - fuel outlet channel, 2 - adjusting washer, 3 - spring, 4 - injector body, 5 - atomizer body, 6 - needle, 7 - nozzle

To identify a faulty injector, follow these steps:

1. Make sure that the engine is working properly and the compression level is the same in all cylinders.

2. Start the engine and warm it up to operating temperature.

3. Loosen the fuel line union nut on the injector to be checked. Note if the engine speed has changed. Carry out the same test at fast idle.

4. With a working nozzle, there will be a clear decrease in engine speed, accompanied by its uneven operation. If the injector being checked is faulty, the change in engine speed will be insignificant and, if present earlier, an extraneous knock will disappear.

Withdrawal

1. Remove air filter.

2. Clean the high pressure fuel lines, unscrew the union nuts on the fuel pump and protect them from contamination.

3. Unscrew the fuel lines from the injectors and close them.

4. Unscrew the nozzles with a socket wrench and remove the copper sealing rings and heat-insulating washers from the holes.

5. Clamp the atomizer body in a vice with soft jaws, disassemble the nozzle and use a wooden tool to clean all parts of the nozzle.

6. The nozzle needle under its own weight must slide tightly into the nozzle seat.

Installation

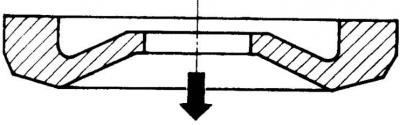

Heat insulating washer

1. Install new heat insulating washers with the bulge upwards into the cylinder head, and then new copper sealing rings.

2. Further installation is carried out in the reverse order of removal.

It is allowed to use nozzles if, after their disassembly, cleaning and subsequent assembly, they restore their functionality and withstand all tests.

Checking the tightness of the atomizer nozzle

Produced on a sprayer tester.

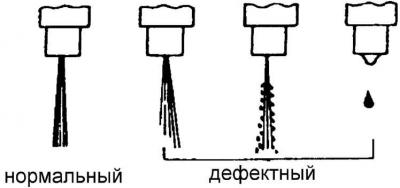

Checking injectors for leaks

Install the nozzle on the device and create a pressure of 2.0 MPa below the opening pressure of the nozzle. If within 10 seconds fuel in the form of a falling drop does not appear on the protruding part of the atomizer around the needle, the atomizer seat is sealed. With a slightly worn atomizer, its protrusion is slightly moistened, without the formation of a drop.

Adjustment of the initial injection pressure

The initial injection pressure is adjusted by installing a gasket under the spring. Increasing the thickness of the gasket increases the injection start pressure, decreasing it reduces it. Changing the gasket thickness by 0.01 mm approximately changes the injection start pressure by 1kg/cm2.

Fuel spray

A prerequisite for the operation of the nozzle is the quality of the spray. The spray pattern must be uniform across the entire cross-section of the spray cone and the spray must be misty. The start and end of the injection must be clear. For new injectors, the injection is accompanied by a sharp sound, for working injectors, the absence of this sound is not a sign of a malfunction.

Visitor comments