Variable Catalytic Converter Gasoline Engines

The combination of an electronically controlled injection system and an oxygen sensor makes it possible to precisely dose the amount of fuel for combustion so that the catalytic converter can reduce the emission of harmful substances. The oxygen sensor is located in the exhaust pipe before the catalytic converter and is flushed by the exhaust gas flow. An oxygen sensor is an electrical sensor that indicates the residual oxygen content in the exhaust gas through fluctuations in electrical voltage and allows conclusions to be drawn about the composition of the air-fuel mixture. In a fraction of a second, the oxygen sensor can transmit a corresponding signal to the injection system control unit and thereby constantly change the quality of the mixture. Firstly, it is necessary, as operating conditions are constantly changing (idle, full load), secondly, optimal afterburning in the catalytic converter occurs only when there is still a sufficient proportion of gasoline in the exhaust gases.

So, in order for afterburning to occur in a catalytic converter at temperatures from +300 to +800°C, the air-fuel mixture must contain more fuel than would be necessary for complete combustion.

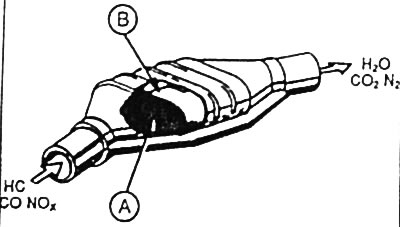

The adjustable catalytic converter in question is a three-way one. This means that in this catalytic converter, thanks to the regulation of the excess air ratio, the oxidation of carbon monoxide is simultaneously carried out (SO) and hydrocarbons (CH), as well as a decrease in nitrogen oxides (NOx).

A - ceramic honeycomb body

B - insulating protective cushion

The catalytic converter consists of a ceramic honeycomb body which is covered with a carrier layer. On the carrier layer are salts of noble metals, which affect the processes of chemical transformations. In the housing, the catalytic converter is fixed with an elastic insulating protective cushion, which, in addition, compensates for thermal expansion. The insulating protective pad is an extremely heat-resistant weave of ceramic fibers.

Catalytic converter for diesel engines

A diesel engine may also have a catalytic converter. No regulation of the composition of the mixture is possible here. The catalytic converter for diesel engines is an oxidizing and non-adjustable type. The oxidation catalytic converter reduces emissions of harmful carbon monoxide and hydrocarbons to levels that are significantly lower than gasoline engines with a variable catalyst. In addition, it reduces the exhaust smoke typical of a diesel engine.

Exhaust gas recirculation system (EGR system) for diesel and DOHC engines

The EGR system keeps the proportion of nitrogen oxides at an insignificant level already before the catalytic converter. Depending on the engine load conditions, the recirculation system directs a certain part of the exhaust gas to the engine intake through an adjustable valve.

This makes it possible to reduce the temperature of the combustion process and, as a result, the proportion of harmful nitrogen oxides in the exhaust gas.

Visitor comments