You will need: socket heads «at 13» And «at 24», screwdrivers with flat and Phillips blades, bit, soldering iron, puller for rotor bearing, hammer, tester.

1. Remove the alternator from the vehicle (see «Removal and installation of the generator»).

2. Mark the relative position of the generator parts.

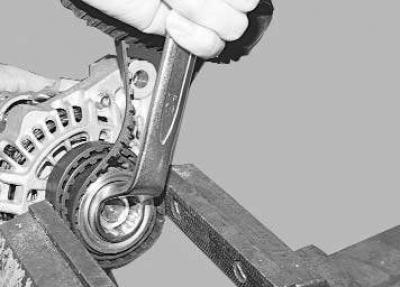

3. Clamp the alternator pulley in a vise, after placing gaskets under it or winding the old belt, unscrew the pulley fastening nut.

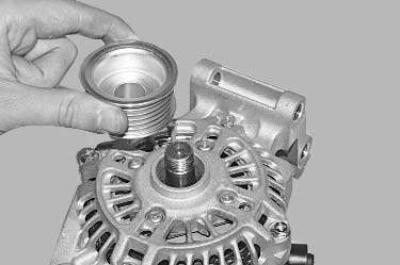

4. Remove the alternator pulley from the vise and remove the pulley from the rotor shaft.

Note. The alternator pulley is fixed from turning on the rotor shaft only due to friction forces after tightening the fastening nut to the required torque. There is no key in the connection.

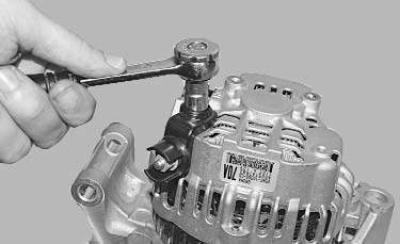

5. Loosen the nut..

6.... and, prying with a screwdriver, remove the generator terminal.

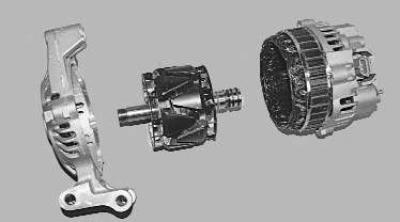

7. Remove the four pinch screws..

8.... prying with a screwdriver, remove the front cover of the generator and remove the anchor.

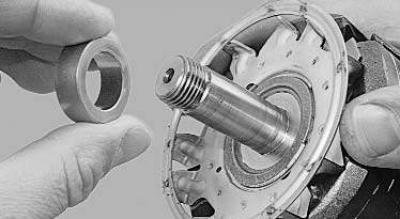

9. Remove the distance ring from the rotor shaft.

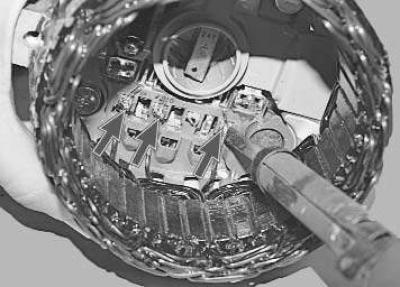

10. Unsolder the three stator winding leads from the rectifier unit and remove the stator.

Note. When desoldering, it is more convenient to use a special device for removing molten solder.

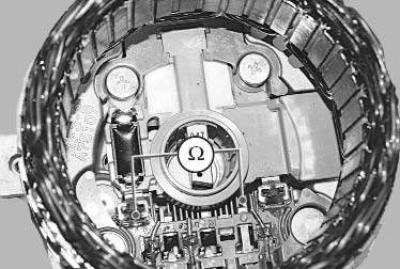

11. From the inside of the cover on the side of the slip rings, unscrew the three fastening screws and remove the brush holder assembly with the rectifier unit and voltage regulator.

Note. The stator leads must already be unsoldered from the rectifier unit during stator removal (see point 10).

12. Examine a cover of the generator from outside a drive. If, during rotation of the bearing, play is felt between the races, rolling or jamming of the inner race, protective collars are damaged or there are traces of grease leakage, replace the bearing. If cracks are found in the cover, especially at the generator mounting points, replace the cover.

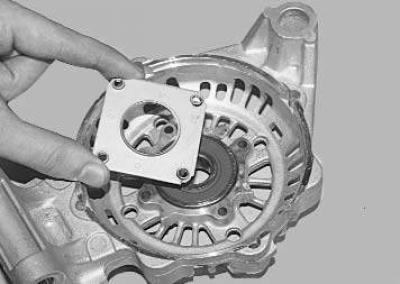

13. To replace the front rotor bearing, unscrew the four screws securing the pressure plate..

14.... and remove the plate.

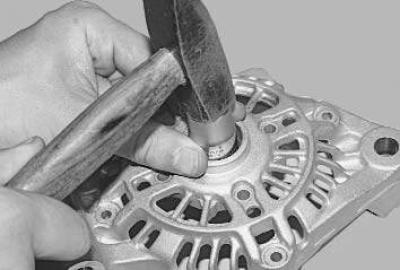

15. Press the bearing out of the cap.

16. With a mandrel of a suitable diameter, press the new bearing into the cover, applying force to the outer race of the bearing.

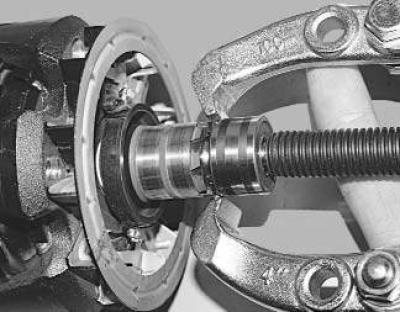

17. Check up ease of rotation of the bearing from slip rings. If, during rotation of the bearing, play is felt between the races, the race is rolled or jammed, the protective cuffs are damaged, or there are traces of grease leakage, replace the bearing. If cracks are found in the cap, replace the cap with a new one.

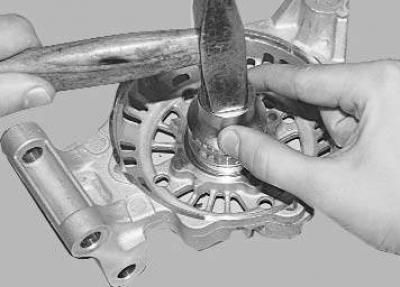

18. Press the bearing off the rotor shaft and install a new one by applying force to the inner race of the bearing with a mandrel of suitable diameter.

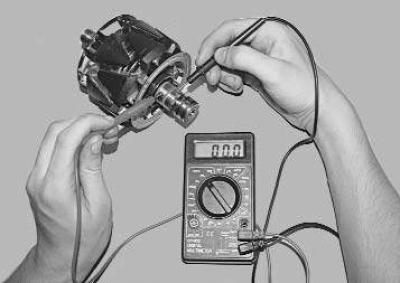

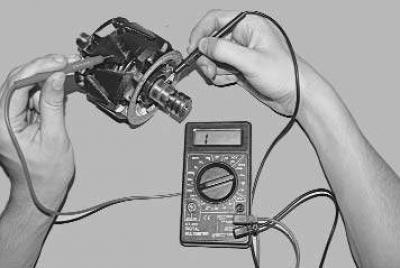

19. Check the resistance of the rotor winding with a tester by connecting it to slip rings. The resistance should be about 3-5 ohms. If the tester shows infinity, then there is a break in the windings and the rotor needs to be replaced.

20. Check the short circuit of the rotor winding for «mass». To do this, connect one probe of the tester to the pole piece of the rotor, and the other in turn to the slip rings. The measured resistance must be infinite, otherwise replace the rotor.

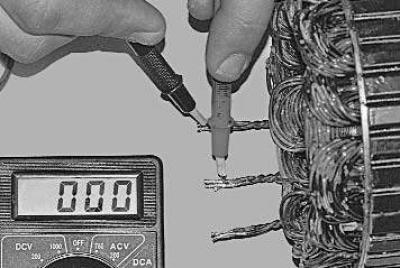

21. Check the stator windings for an open circuit, alternately measuring the resistance between all winding leads with a tester. If the measured resistance tends to infinity, the stator must be replaced.

22. Connect the tester probes to the stator housing and, in turn, to each winding output. The measured resistance must be very large (strive for infinity). Otherwise, replace the stator.

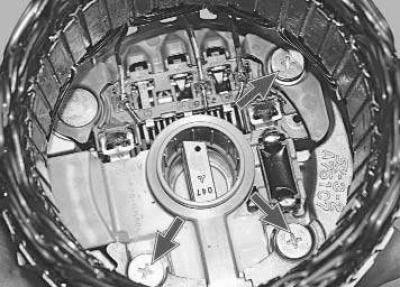

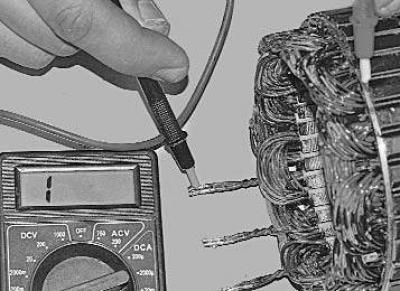

23. Check the rectifier unit. To do this, connect one tester probe to the output of the stator phase winding, and the second probe to the air cooler of positive diodes. Swapping the probes of the tester in places, measure the resistance. If the tester readings are the same in both cases, the rectifier unit is faulty and needs to be replaced.

24. Similarly, check the negative diodes.

25. Check up protrusion of brushes in a free condition. If the measurement is less than 3 mm, replace the brushes or brush holder assembly.

Note. To replace the brushes, you will need to unsolder their wires from the brush holder leads.

26. Assemble the generator in the reverse order of removal, orienting the covers of the generator and the stator housing according to the previously made marks.

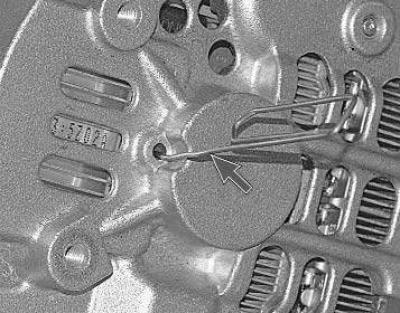

Note. Before installing the cover on the side of the slip rings of the rotor, sink the brushes and fix them in this position by inserting a pin into the hole in the cover (e.g. an unfolded paper clip). After assembly, remove the pin.

Visitor comments