- Check up a condition of a spring of a conducted disk;

- Check up a condition of frictional overlays of a conducted disk. If the distance from the lining surface to the top side of the rivet heads is less than 0.20 mm, replace the disk;

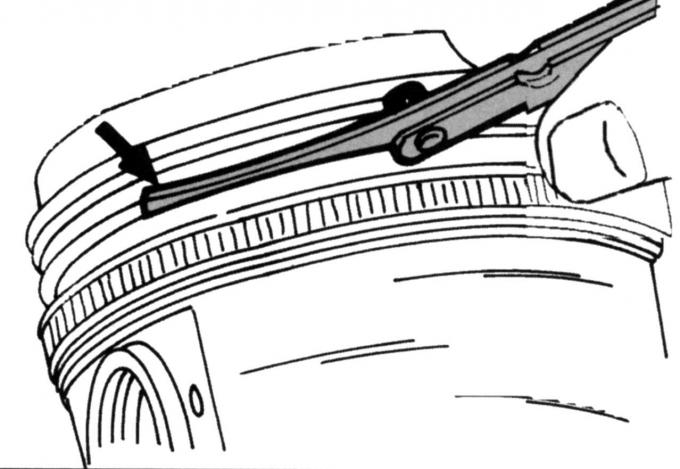

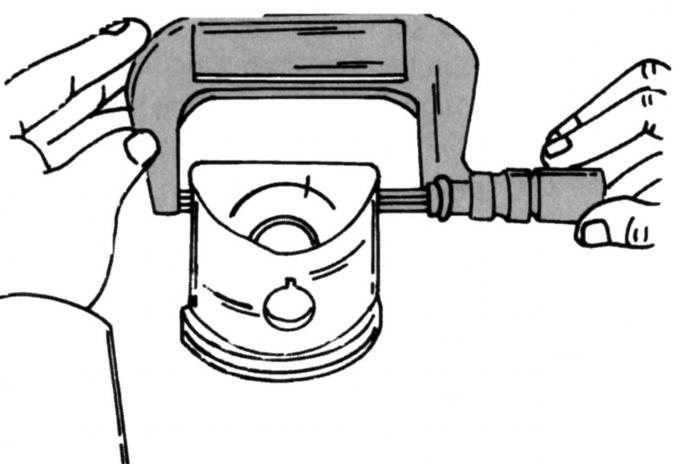

Pic. 144. Measuring the runout of the clutch disc

- Check up a conducted disk on palpation. To do this, install it in a special mandrel in the lathe chuck. Install a dial indicator with a special bracket next to the disc so that the measuring rod rests on the outside of the disc (pic. 144). Slowly scroll the disc and read the indication on the dial indicator. If the runout is more than 0.8 mm, replace the disc;

- check landing of a nave of a conducted disk on splines of a primary shaft of a transmission. To do this, put on the disk and grasp it along the outer edge between the thumb and forefinger. Move the disc in the direction of rotation back and forth. If the play is more than 0.4 mm, then there is wear in the wedge engagements;

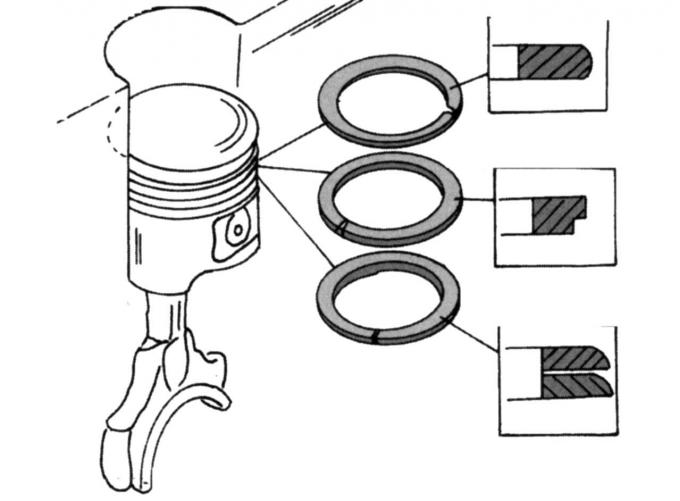

Pic. 145. Places of increased wear of the petals of the clutch diaphragm spring

- check the wear of the ends of the petals of the diaphragm spring (pic. 145);

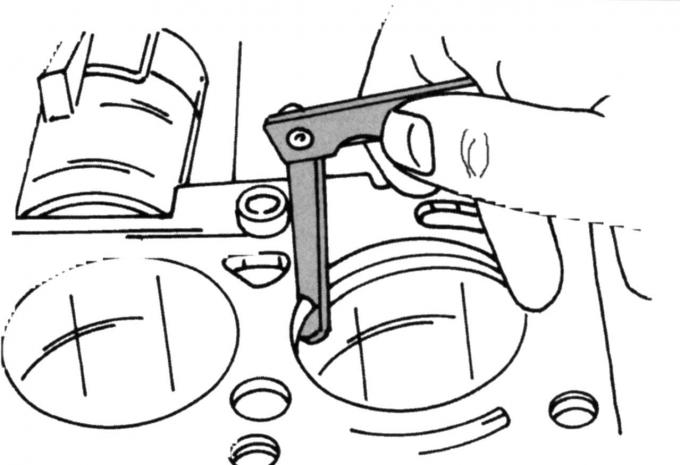

Pic. 146. Checking for wear or misalignment of the clutch pressure plate

- Check the clutch pressure plate. The rubbing surfaces and ends of the petals of the diaphragm spring are most subject to wear. Wear at the ends of the petals of the clutch diaphragm spring should not exceed 0.3 mm. Place the measuring ruler on the surface and measure with a feeler gauge at the location shown in fig. 146, and elsewhere throughout the surface. If the gap in these places is more than 0.08 mm, the pressure plate must be replaced;

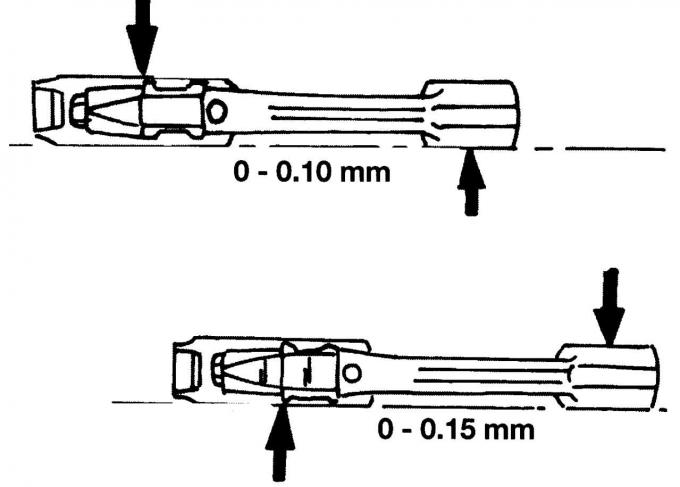

Pic. 147. Checking the flywheel for runout (only when changing the flywheel)

- Check up a rubbing surface of a flywheel on presence of deep dredging. The flywheel can be checked with a dial gauge, either with the engine installed or removed. To do this, install a dial indicator on the cylinder block (pic. 147). Install the measuring rod on the rubbing surface. Set the dial indicator to zero, turn the flywheel to the right several times and observe the deflection of the arrow. The flywheel runout should be no more than 0.10 mm.

Visitor comments