Engines produced before May 1998

Disconnect the battery;

- Establish a forward part of the car on support;

- remove the mudguard under the car (nine screws);

- Remove the right forward wheel;

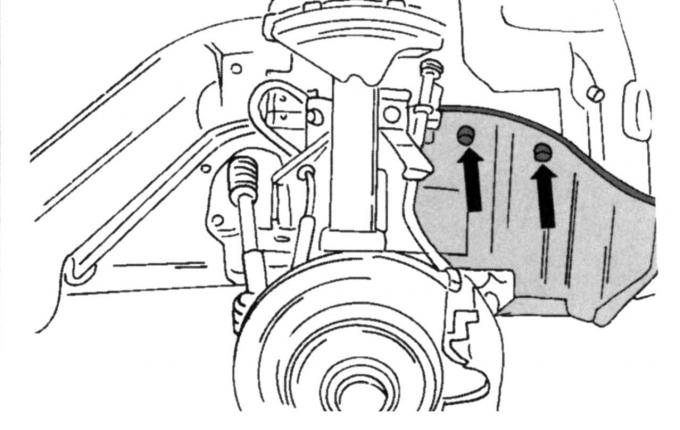

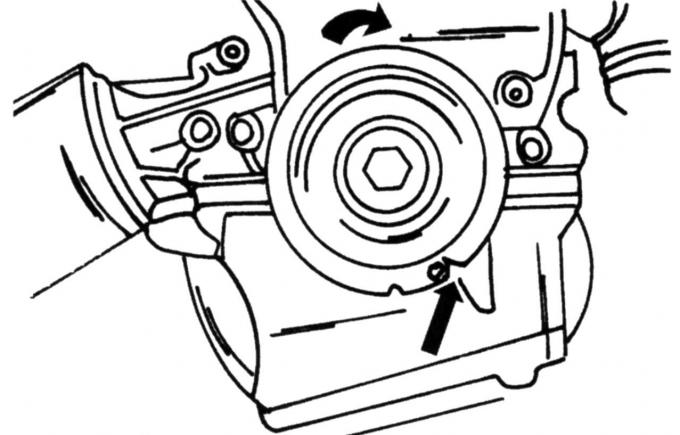

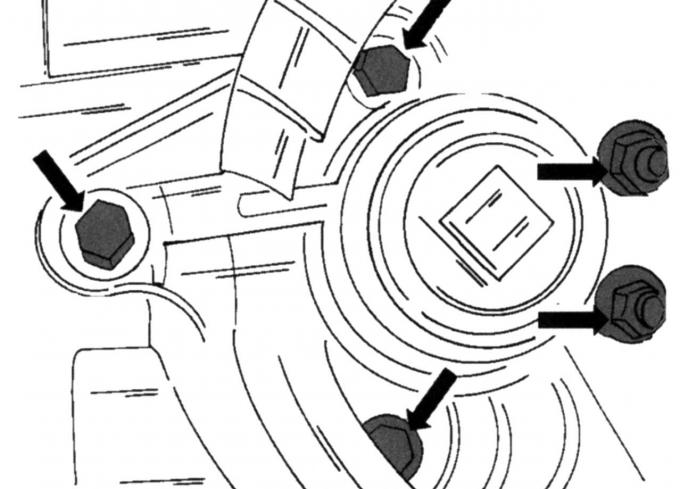

Pic. 96. Cover attachment points on the inside of the wheel arch

- on the inside of the wheel arch, unscrew the cover. It is fixed in the places shown in Fig. 96;

- Remove the V-ribbed belt, as described in the relevant subsection;

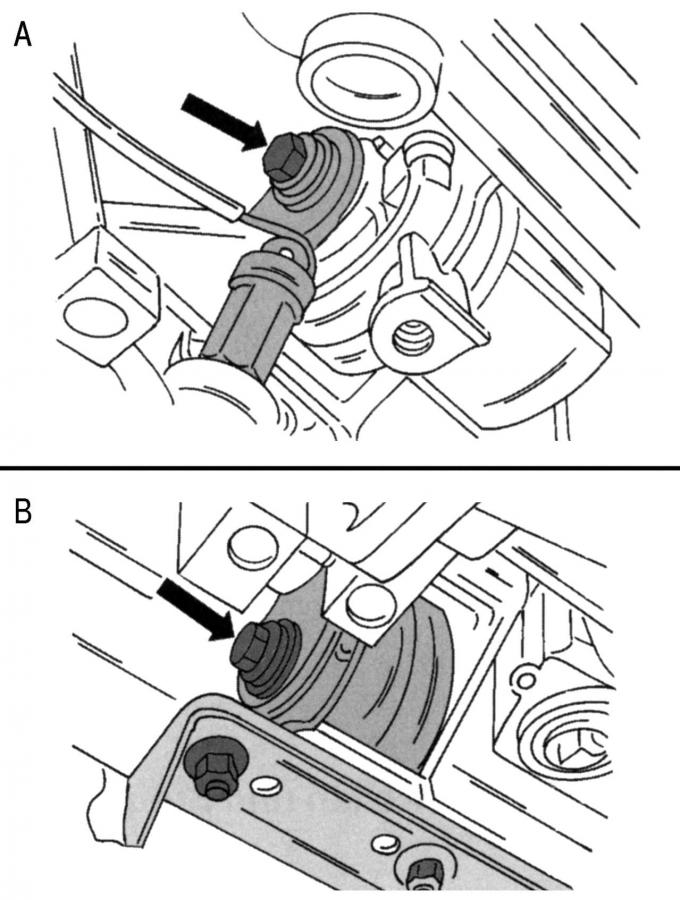

Pic. 97. Loosening the screws of the stops from turning (on vehicles with automatic transmission): A - on the right side, B - on the left side

- on vehicles with a manual transmission, loosen the horizontally inserted screw of the right anti-rotation stop (similar to that shown in Fig. 97, V);

- on vehicles with automatic transmission, loosen the screws (pic. 97) left stop from turning;

- Turn away screws of a pulley of the liquid pump and remove a pulley;

- lock the crankshaft from turning, unscrew the pulley screw and remove the pulley. If necessary, press out with two tire mounting levers;

- unscrew the lower protective cover of the toothed drive belt (three attachment points);

- lower the car on wheels;

- Remove the air intake hose as described when removing the cylinder head;

- unscrew the expansion tank (two screws) and put it aside;

- place a jack under the oil pan (with wooden spacer between oil pan and car jack head) and raise the power unit until the engine mount on the front side is unloaded;

Pic. 32. Attachment points of the right engine mount

- Unscrew the suspension bracket of the engine, shown in fig. 32;

- release the plug of the lambda probe from the spring clip and remove it;

- unscrew the middle and upper protective covers of the toothed drive belt by removing the running roller of the poly-V-belt;

- Remove the spark plug tips and cylinder head cover (ten screws);

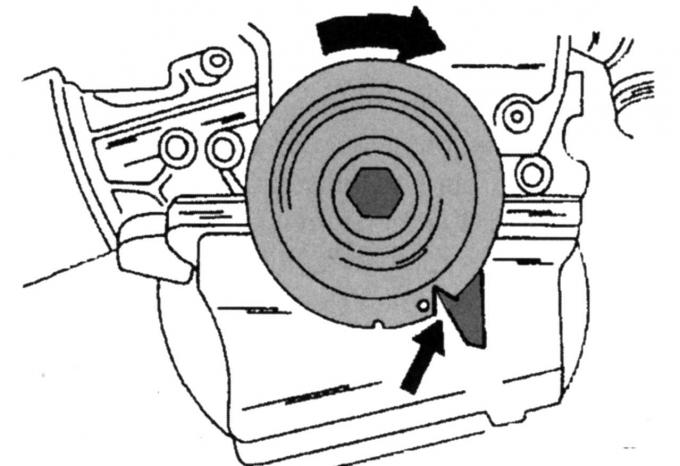

Pic. 64. Setting the crankshaft to top dead center (TDC)

- Turn a cranked shaft so that cut in a pulley was against marking, as it is shown in fig. 64;

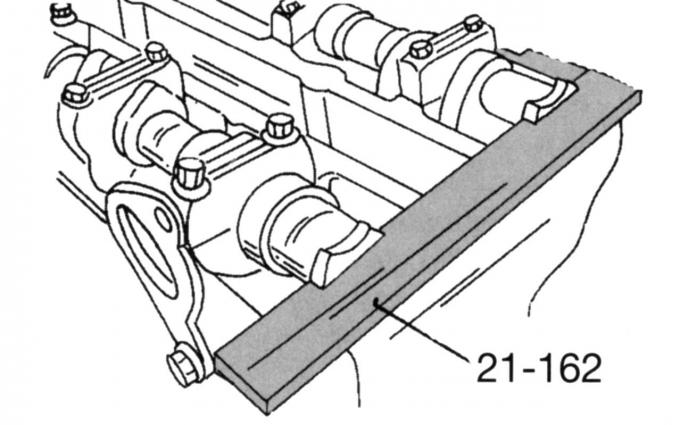

Pic. 63. Caliber for adjusting the valve timing

- fix both camshafts in this position (see fig. 63);

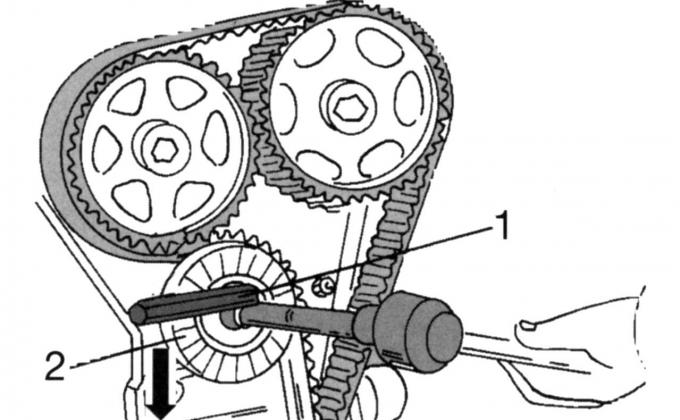

Pic. 98. The weakening of the tension of the toothed drive belt: 1 - nut; 2 - roller

- Loosen the toothed drive belt. To do this, loosen screw 1 (pic. 98) and insert a suitable Allen key in the location shown in the illustration. Turn the tensioner in the direction of the arrow and tighten the tensioner again in the new position. Remove the toothed drive belt;

Note: If you do not have a camshaft adjustment gauge, mark the pulleys and camshafts.

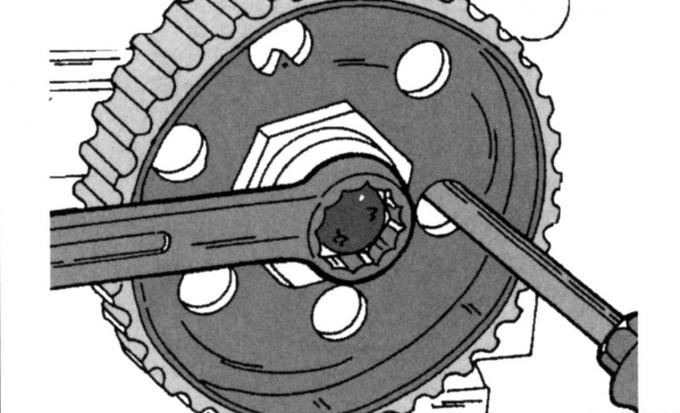

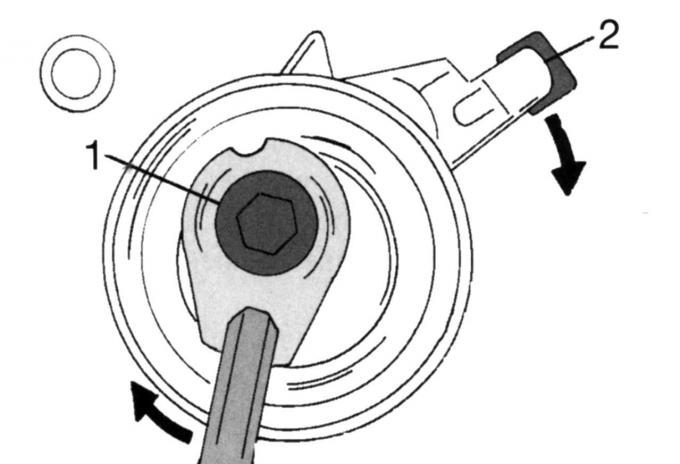

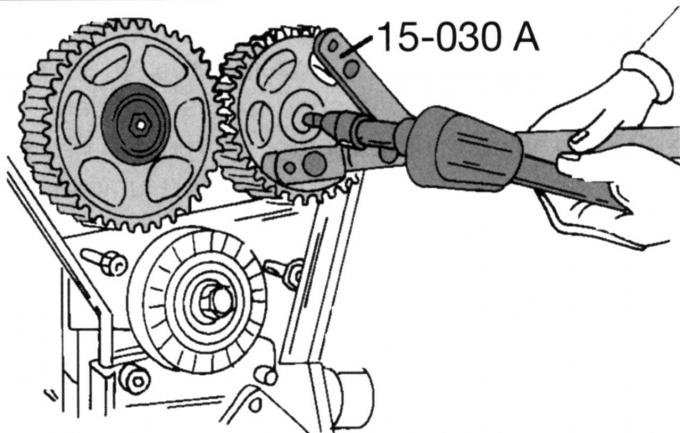

Pic. 99. Holding the camshaft drive gear from turning

- loosen the fixing screws of both camshaft pulleys, securing the shafts from turning. Insert the mandrel into one of the holes as shown in fig. 99 and carefully support it against the cylinder head. The pulleys must turn freely on the shafts.

If it is necessary to install the same toothed drive belt again, protect it from contamination with liquid or grease. In no case do not clean the belt, you can wipe it with a dry cloth. After a very long run, check the camshaft pulleys for tooth wear. There should be no detachments on the belt.

When installing the toothed drive belt, proceed as follows:

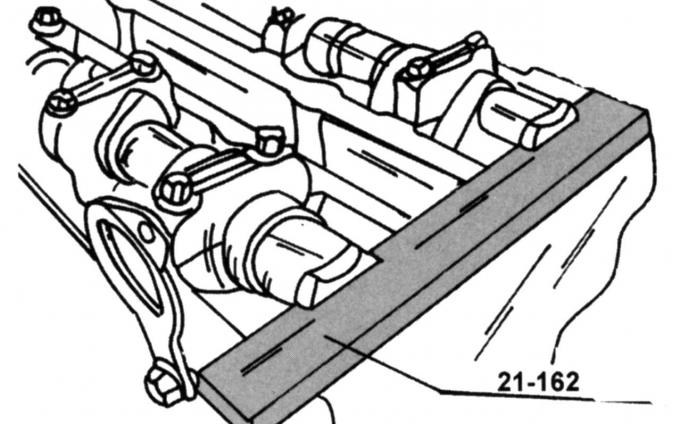

Pic. 100. Caliber (21-162) for variable valve timing, mounted on camshafts

- insert the gauge for adjusting the valve timing, as shown in fig. 100;

Pic. 101. Crankshaft at TDC

- Turn the crankshaft until the notch on the pulley is in the position shown in fig. 101. It corresponds to TDC. With the toothed drive belt removed, turn the shaft very slowly so that the valves do not hit the pistons;

Pic. 102. Pre-tensioning device for tensioning the belt: 1 - support bolt; 2 - tension spring; 3 - screw

- if the belt tensioner spring has been removed, it must be reattached. To do this, screw in the support bolt 1 (pic. 102) and tighten it with a torque of 10 Nm, hang the spring 2 between the bolt and the belt tensioner. Install the Allen key as shown in the illustration and turn in the direction of the arrow. Then tighten the tension roller with screw 3 in the new position;

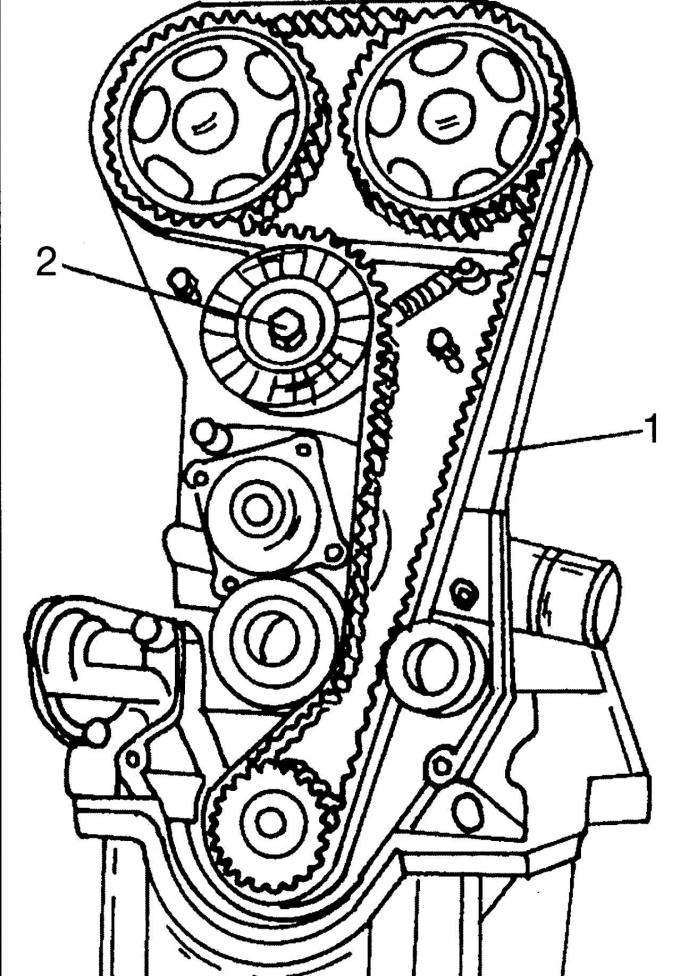

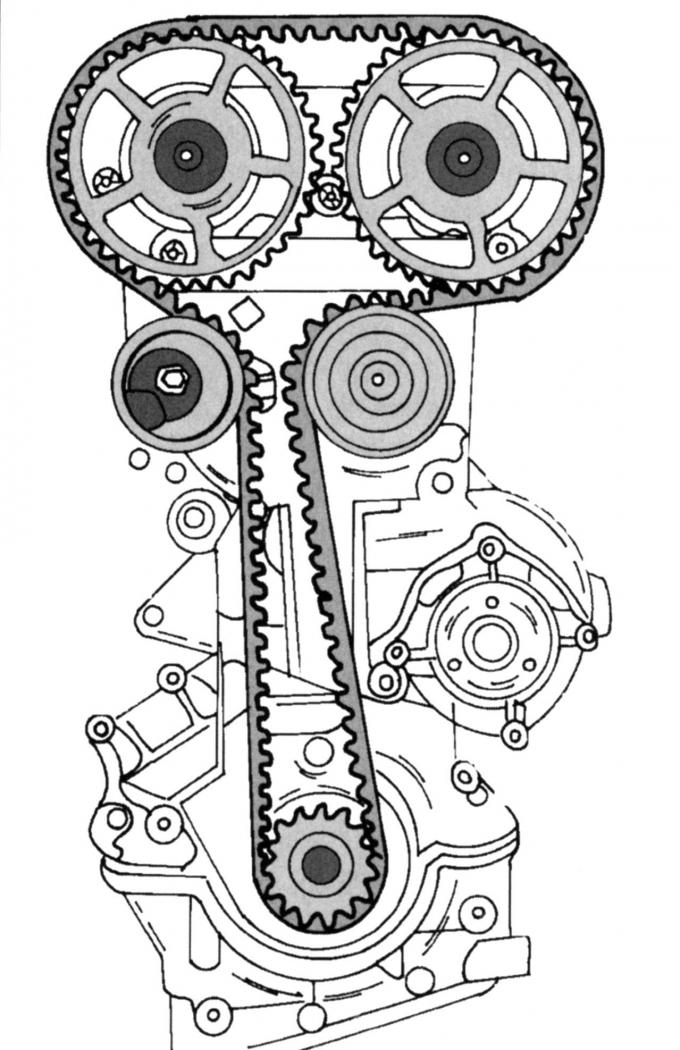

Pic. 66. Placement of the toothed drive belt: 1 - belt, 2 - screw

- Lay the toothed drive belt on the three pulleys and the tensioner in a counterclockwise direction. First, lay the belt on the crankshaft timing gear. Keeping the teeth engaged, route the belt on the left around the lower idler pulley and idler pulley and loop around the left camshaft pulley. While holding the belt firmly in engagement with the teeth of the camshaft pulley, route the belt over the right pulley and finally around the inside of the right idler pulley. Make sure all teeth are engaged. Loosen nut 2 (see fig. 66), after which the device will provide the required belt tension. Tighten the nut to 38 Nm;

- lock the camshaft pulleys from turning and tighten both screws to 68 Nm. In this case, the crankshaft must not rotate. After tightening the screws, turn the crankshaft two turns until the piston is again at TDC;

- check that the gauge is still aligned according to fig. 63 when the crankshaft is at TDC. Otherwise, loosen the corresponding camshaft pulley and move it slightly. Tighten the screw again to 68 Nm;

- Establish a cover of a head of the block of cylinders with a new sealing lining. Tighten the screws evenly around the circumference, first to 2 Nm and then to 7 Nm;

- screw in the spark plugs (15 Nm) and put the high voltage wires on the candles in accordance with the order of operation of the cylinders;

- Install the middle protective cover of the toothed drive belt and then the top cover. The middle cover should freely engage with the bottom cover. Screw on the left side of the running roller of the V-ribbed belt (48 Nm);

- Fix a time of the engine with new self-locking nuts. The center punch mark must be aligned with the mark on the hanger bracket. Tighten four nuts on the engine and one nut on the engine mount to 83 Nm;

- lower the car on wheels;

- Establish a broad tank of system of cooling and an inlet pipe. After that, put the car on supports again;

- on vehicles with automatic transmission, tighten the middle screw of the right anti-rotation stop to 120 Nm (see fig. 97, A), on vehicles with a manual transmission, tighten the screws of the left and right stops with the same torque;

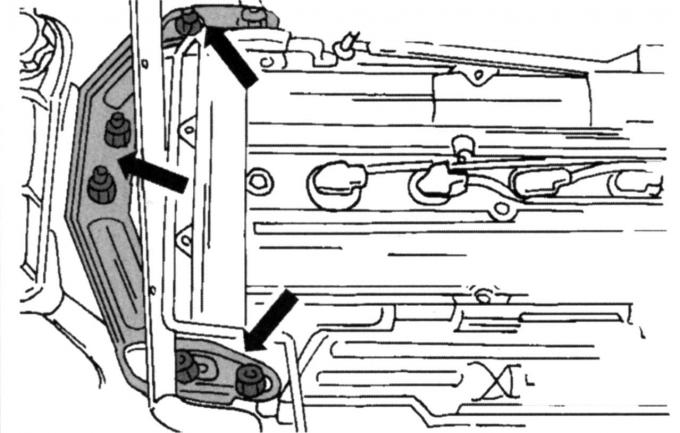

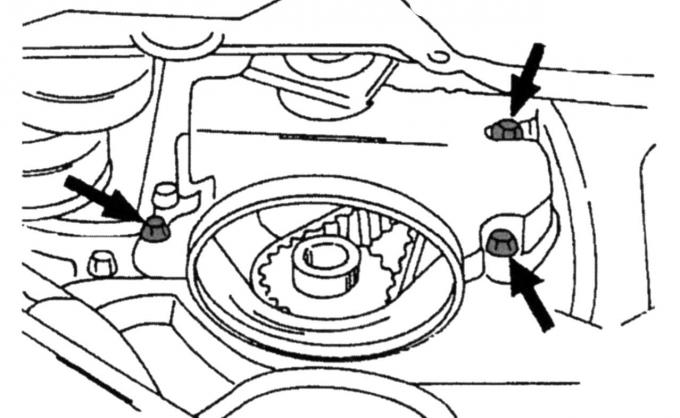

Pic. 103. Attachment points of the lower cover of the toothed drive belt (on engines manufactured since May 1998, one screw is used, respectively, on the left and right)

- screw the lower protective cover of the toothed drive belt (pic. 103);

- screw the belt pulley of the liquid pump;

- fit the crankshaft pulley (vibration damper) and lock the crankshaft from turning (turn on the transmission). Tighten the screw to 115 Nm;

- Install the V-ribbed belt and tighten it as described in the relevant subsection;

- carry out all other works in the reverse order of removal. Make sure that any plugs, high-voltage spark plug leads, hoses, etc. rejoined in their original positions. Do not forget that the coolant is drained;

- tighten the wheel nuts (130 Nm), if the front wheel was unscrewed;

Release engines from May 1998

- disconnect the storage battery;

- Establish a forward part of the car on support;

- unscrew the mudguard under the car (nine screws);

- Remove the right forward wheel;

- on the inside of the wheel arch, unscrew the cover. It is fixed in the places shown in Fig. 96;

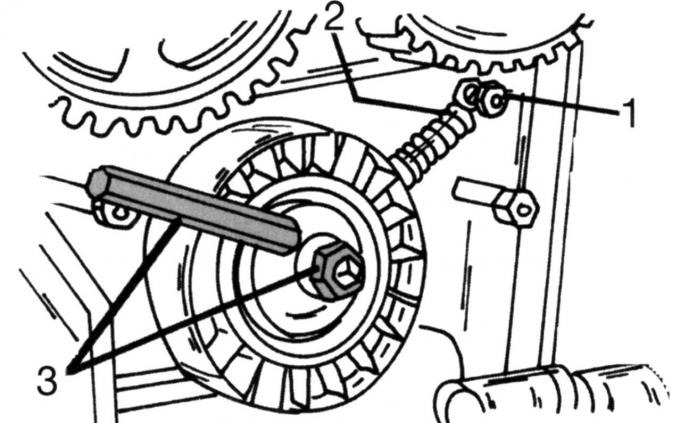

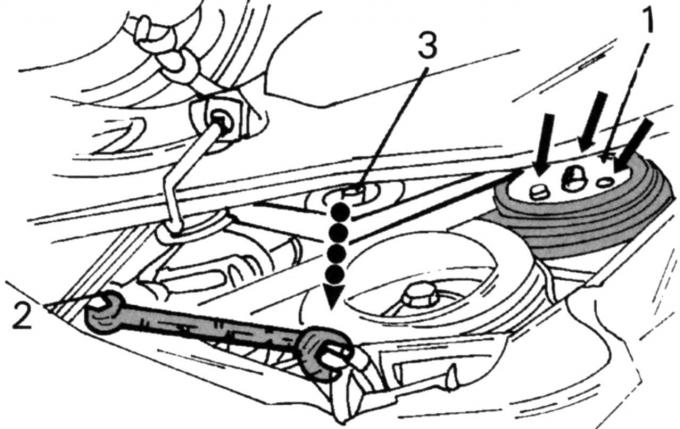

Pic. 104. Removing the V-ribbed belt on the engines of release from May 1998: 1 - screws; 2 - key; 3 - tension roller

- remove poly V-belt (pic. 104);

- lock the crankshaft from turning, unscrew the pulley screw and remove the pulley. If necessary, press out with two tire mounting levers;

- unscrew the lower protective cover of the toothed drive belt (two attachment points - left and right);

- Remove the expansion tank;

- place a jack under the oil pan (with wooden spacer between oil pan and car jack head) and raise the power unit until the engine mount on the front side is unloaded;

Pic. 70. Attachment points of the front engine mount

- Turn away the suspension bracket of the engine shown on fig. 70. Pre-mark the exact position for installing the suspension;

- unscrew the top protective cover of the toothed drive belt (two screws left and right), but do not remove it;

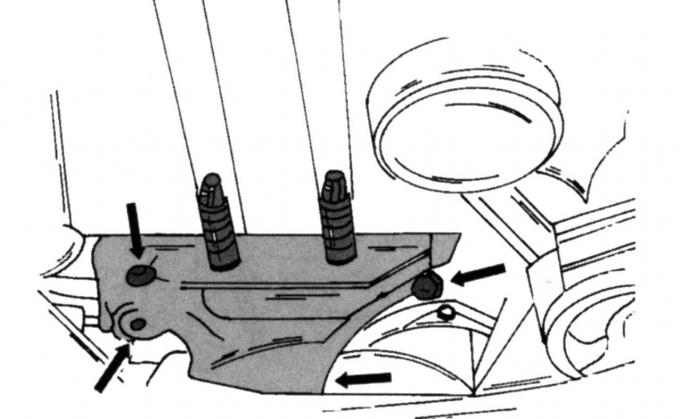

Pic. 105. Attachment points of the middle protective cover of the toothed belt

- remove the middle protective cover of the toothed drive belt together with the engine mount bracket (pic. 105). Now you can remove the top cover;

- remove the high voltage wires from the spark plugs one by one (pull the tips straight and up). Remove the cylinder head cover (ten screws) and remove the gasket;

- Turn out spark plugs;

- check that the piston is at TDC (see fig. 64);

Pic. 71. Loosening the toothed drive belt: 1, 2 - screws

- loosen the toothed drive belt tension (see fig. 71). To do this, unscrew nut 1 and install a suitable hexagon socket wrench in the place shown in the figure. Turn the belt tensioner in the direction of the arrow. Loosen screw 2 four turns and disengage the belt tension roller. Remove the toothed drive belt, do not oil it or break it if you use it again;

Pic. 45. Camshaft gear holding tool

- Loosen the fixing screws of both camshaft pulleys, keeping the shafts from turning. The clamp shown in fig. 45 is best suited for this purpose. Otherwise, insert a drift into one of the holes and carefully lock it against the cylinder head. Remove both pulleys, marking their location for later installation.

Note: If you do not have a camshaft adjustment gauge, mark the pulleys and camshafts.

If it is necessary to install the same toothed drive belt again, take care not to contaminate it with liquid or grease. In no case do not clean the belt, you can wipe it with a dry cloth. After a very long run, check the camshaft gears for tooth wear. The belt must not have material delaminations.

When installing the toothed drive belt, proceed as follows:

- to fix the crankshaft at the service station, a special caliber is used, which is screwed into the cylinder block; you will need the camshaft setting gauge already mentioned on pre-May 1998 engines. Insert this gauge as shown in fig. 100;

- turn the crankshaft until the notch on the pulley is set to the TDC position shown in fig. 101. With the toothed drive belt removed, turn the shaft very slowly so that the valves do not hit the pistons;

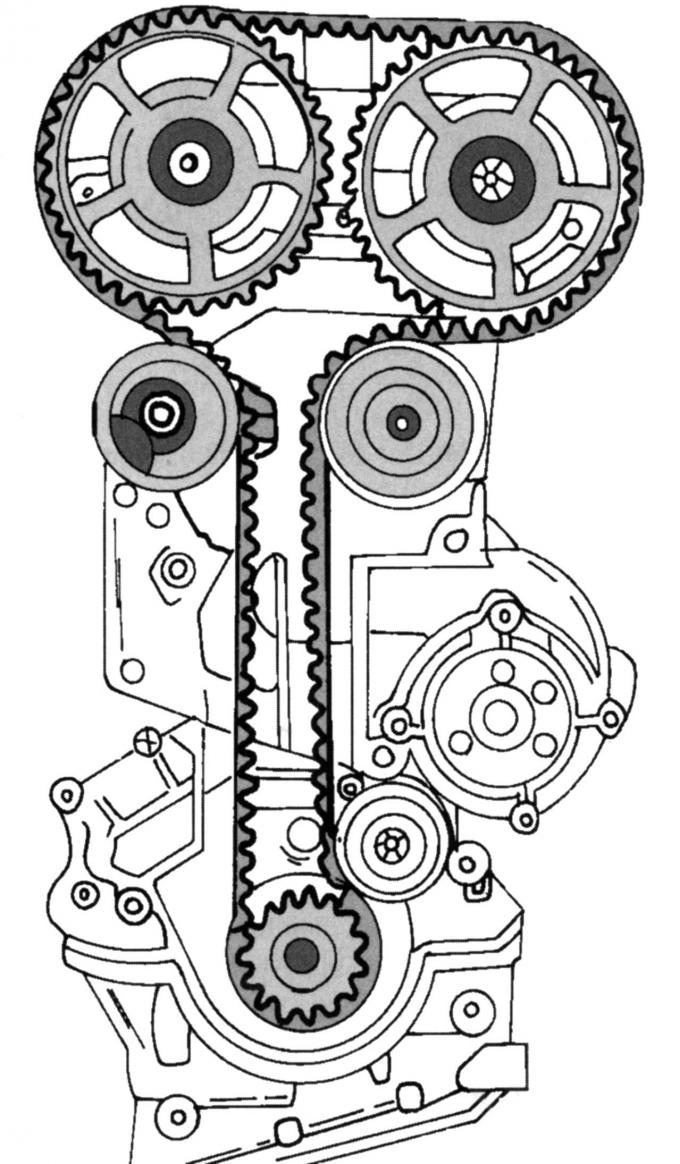

Pic. 106. Placement of a toothed drive belt on engines manufactured before January 1999

- until January 1999, the toothed drive belt was laid in the manner shown in fig. 106 when there is an additional tension roller at the bottom. Lay the toothed drive belt in a counterclockwise direction over the three pulleys and the belt tensioner. First, place the belt on the crankshaft pulley, keeping the teeth engaged, loop the belt around the top left of the idler pulley and both camshaft pulleys, and then pull the belt as shown around the inside of the right and lower pulleys. Make sure that all teeth are engaged;

Pic. 107. Placement of a toothed drive belt on exhaust engines from January 1999

- starting from January 1999, the lower roller was not used, the belt began to be laid, as shown in fig. 107. The toothed drive belt is laid in the manner described above;

Note: There is a tongue on the timing belt tensioner. When laying the belt, it must not be caught on the metal cover.

- in accordance with fig. 71 hook the belt tensioner onto the metal cover and hand-tighten the screw;

- tighten the toothed drive belt by turning the tension roller to the left (in the direction of the arrow) until the marked arrow and the line match. In this position, tighten the screw in the middle of the belt tensioner to 25 Nm;

- lock the camshaft pulleys from turning and tighten both screws to 68 Nm. In this case, the crankshaft must not rotate. After tightening the screws, turn the crankshaft two turns until it is at TDC again;

- check that the gauge is still aligned according to fig. 63 when the crankshaft is at TDC. Otherwise, loosen the corresponding camshaft pulley and move it slightly. Tighten the screw again (screws) torque 68 Nm;

- Establish a cover of a head of the block of cylinders with a new sealing lining. Tighten the screws evenly around the circumference, first to 2 Nm and then to 7 Nm;

- screw in the spark plugs (15 Nm) and put the high voltage wires on the candles in accordance with the order of operation of the cylinders;

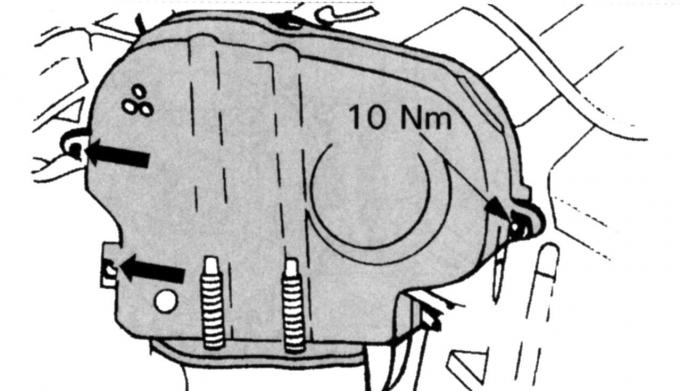

Pic. 108. Attachment points for the upper protective cover of the toothed drive belt on engines manufactured since May 1998

- Establish the top protective cover of a gear driving belt together with an average cover. Tighten the middle cover fastening with the engine mount support bracket to 50 Nm. Check that the top cover seal is tight and that the screws (pic. 108) were tightened with a torque of 10 Nm;

- Establish a forward support of the engine. Tighten the screws and nuts to 83 Nm. After that, you can remove the jack;

- Install the expansion tank;

- install the lower protective cover of the toothed drive belt and tighten both screws with a torque of 7 Nm;

- fit the crankshaft pulley (vibration damper) and lock the crankshaft from turning, turn on the gear. Tighten the screw to 115 Nm;

- Install the V-ribbed belt and tighten it as described in the relevant subsection;

- carry out all other works in the reverse order of removal. Make sure that any plugs, high-voltage spark plug leads, hoses, etc. joined again in their former places;

- tighten the wheel nuts (130 Nm), if the front wheel was removed.

Checking the technical condition of the camshafts

If scratches and cracks are found, replace the camshaft (shafts) or cylinder heads.

To check the diameter and ovality, measure the camshaft bearing journals with a micrometer. Compare the found values with the inner diameters of the bearing holes in the cylinder head and with the technical data (see Attachment), to determine the status of the parts.

The play of the camshaft bearings can be measured in the same way as the play of the crankshaft main bearings - with a plastic rod «Plastigage». Screw on the bearing caps to flatten the rod and then unscrew them again. Measure the flattened rod width and compare with the required value, which is 0.020-0.070 mm.

If there is too much play, replace the camshaft and (or) cylinder head.

Visitor comments