- install the engine and drive on a car jack, ask an assistant to support the engine and drive well and drive them into the required position in the engine compartment;

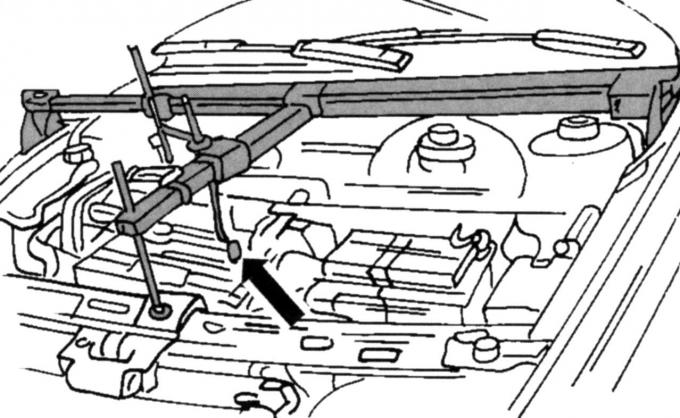

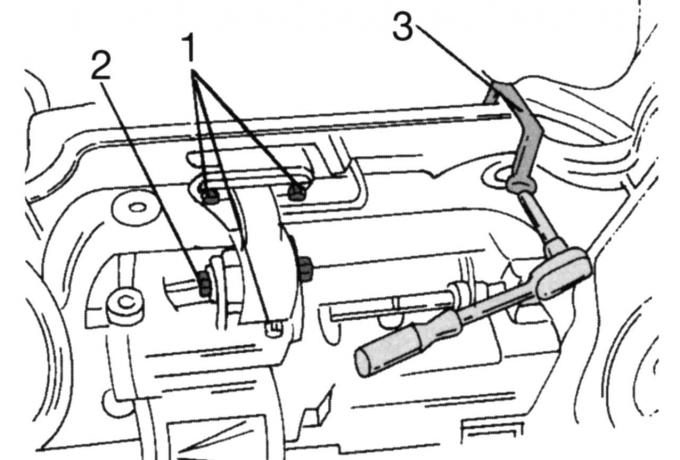

Pic. 34. Device for lifting the engine and drive when hanging the engine

- install the lifting device as shown in fig. 34. In its absence, you can use a lifting mechanism with a cable in the eye. It is important that the engine can be lifted until it is connected to the suspension mounts;

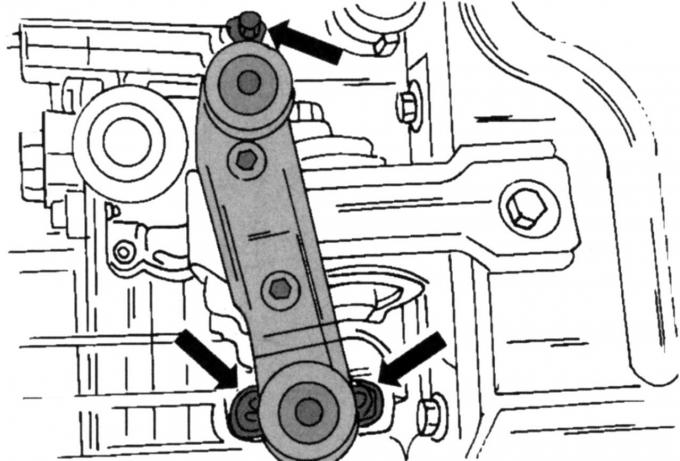

Pic. 33. Attachment points of the left suspension on the drive

- fix the left engine mount (see fig. 33) on the gearbox without tightening the nuts. Always replace nuts with new ones;

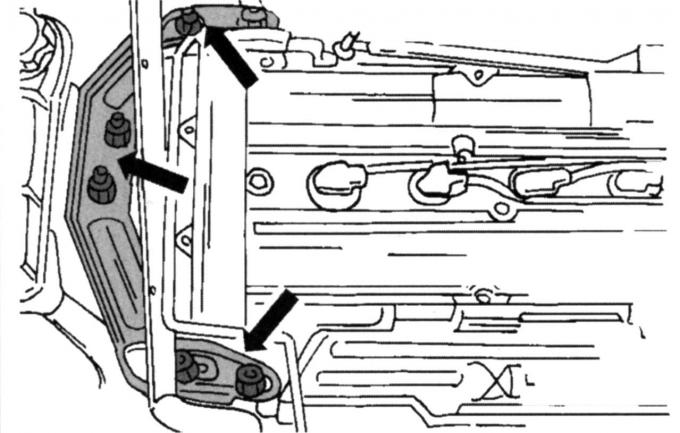

Pic. 32. Attachment points of the right engine mount

- install the right engine mount (see fig. 32). Do not tighten the nuts;

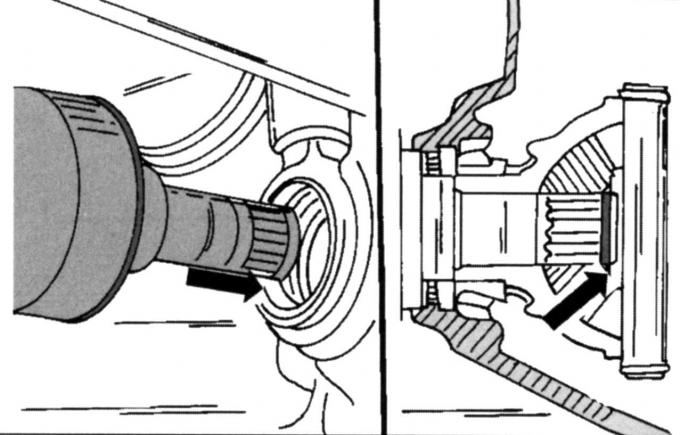

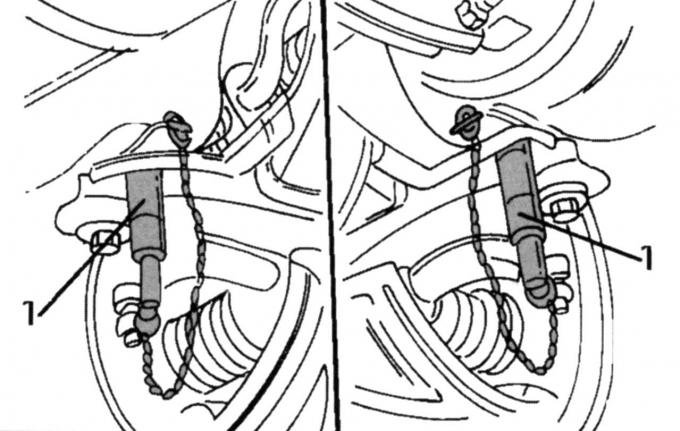

Pic. 35. Installation of the left drive shaft. Safety ring location

- Establish the left drive shaft in a transmission. Properly install the new circlip into the groove of the shaft before the end of the shaft is inserted into the gearbox (pic. 35);

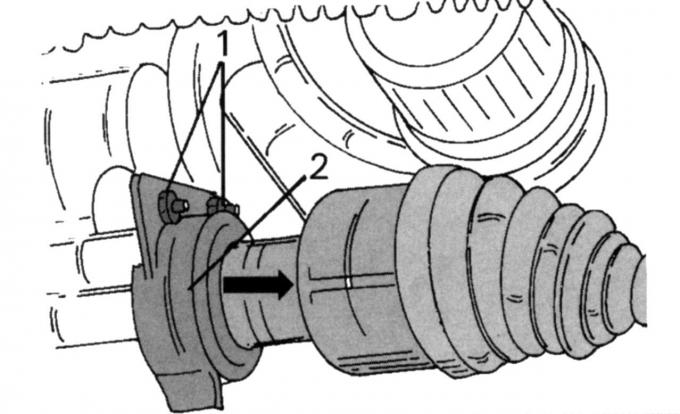

Pic. 30. Removing the right wheel drive shaft: 1 - thrust ball bearing screw; 2 - thermal shield

- slide the right drive shaft into the gearbox, install the thrust bearing and tighten both screws 1 shown in fig. 30, torque 27 Nm. Then install the heat shield 2;

- insert and secure the low pressure hose of the power brake booster into the quick-release fastener. By pulling out the hose, make sure that it is firmly fixed;

- install the air conditioning compressor, if installed (tighten the four screws to 25 Nm) and insert the electromagnetic clutch plug;

- connect the heating hose to the heating pipe, and the lower radiator hose to the branch pipe and fasten it to the heating pipe with a clamp;

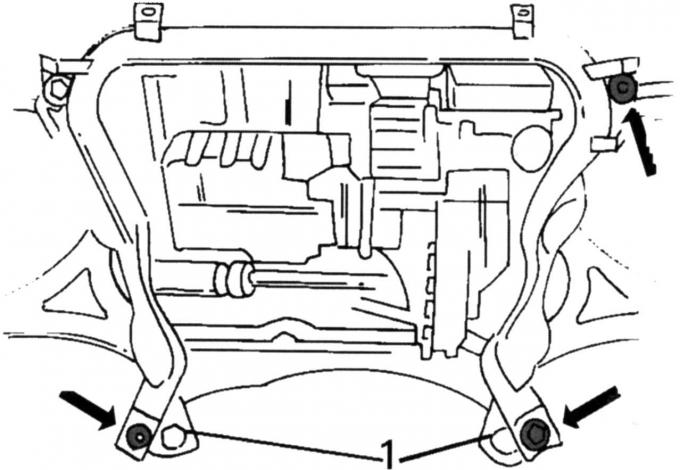

Pic. 36. Using the guide pins to center the subframe

- hang out the subframe, but first unscrew the radiator fasteners and the front stop from turning from the subframe. Now install both guide pins 1 (pic. 36), to the indicated locations and align the subframe so that the guide pins are in the middle of the holes in the body. Also set the steering to the desired position. On fig. 37 shows the bottom where the inserted pins are. If you do not have pins at your disposal, you need to mount the subframe according to the marking made earlier. Tighten the screws shown in fig. 37 to a torque of 130 Nm and unscrew both guide pins 1 again, if used;

Pic. 37. Location of screws (indicated by arrows) subframe: 1 - guide pins

- insert the middle screw of the front anti-rotation stop without tightening the nut firmly;

- tighten the three nuts shown in fig. 33, torque 83 Nm. The engine mount must not twist;

- tighten nuts (see fig. 32). Tighten the four nuts on the engine first. Tighten both suspension bracket nuts after the engine weight has loaded the suspensions, i.e. the lifting device used must first be removed. The tightening torque of all nuts is 83 Nm;

Pic. 29. Location of the console fixing screws

- install the console of the rear stop against rotation on the gearbox and tighten with a torque of 84 Nm (see fig. 29);

Pic. 38. Mounting the rear stop against turning and steering (tightening torques: 1 - 48 Nm; 2 - 120 Nm; 3 - 130 Nm)

- Fasten the back stop against turning and the steering to the subframe, as shown in fig. 38. The figure also shows a special wrench for tightening the steering screws. Tighten the front stop with 120 Nm.

The rest of the work is carried out in the reverse order of removal:

- attach the gearbox mechanism with a torque of 44 Nm to the bottom of the body;

- tighten the clamping screw of the roller bar to 23 Nm, and the fixing screw of the support rod to 55 Nm. The gearbox must be installed in «neutral». Align the clamp according to the marking and tighten the clamping screw with a torque of 16 Nm. Check later if the gear shifts freely. Fill the gearbox with oil;

- install the front wheel suspension (see relevant chapter);

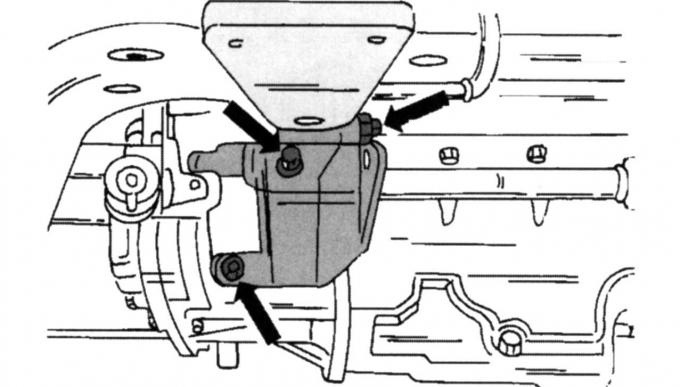

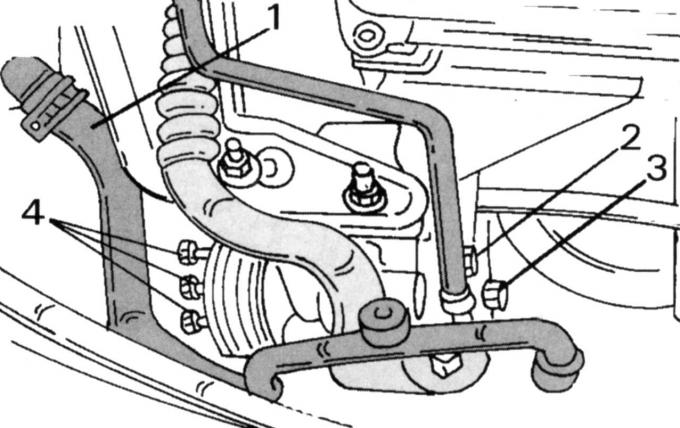

Pic. 28. Attachment of the auxiliary steering pump: 1 - hose; 2 - mounting clamps; 3, 4 - fixing screws

- as shown in fig. 28, tighten screws 3 and 4 to 47 Nm. Reinstall the clamp and attach the hose to the expansion tank of the cooling system;

- tighten the cable fastening «masses» between the gearbox and the body torque 47 Nm;

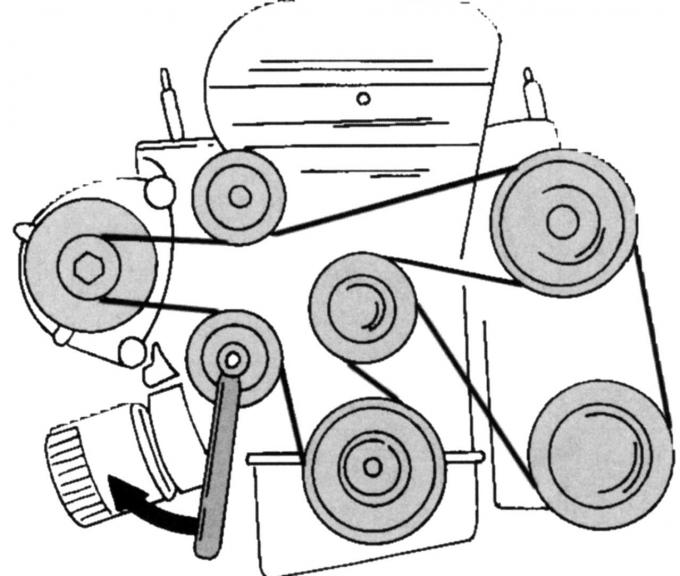

Pic. 39. The direction of rotation of the tension roller when installing the belt

- put on a driving belt according to fig. 39 and adjust the tension with the tensioner in the direction of the arrow;

- Install the exhaust system on the rubber rings and tighten the connection on the exhaust manifold to 40 Nm;

- Connect the fuel lines with quick-acting locks. Wiring is color coded;

- after lowering the vehicle onto the wheels, tighten the wheel nuts to 85 Nm.

Visitor comments