To control the voltage, disconnect the connector on the injection valve, connect the LED indicator to the connector (in no case a control light).

Start the engine. The indicator LEDs should flash, otherwise no voltage is applied. It is also possible that the control unit is faulty. But you can install this only in the workshop.

To measure the resistance, disconnect the connector on the injection valve, connect a multimeter to both valve contacts. At 20°C, the resistance should be within 14.5±1 ohm.

If the value is very different, replace the valve.

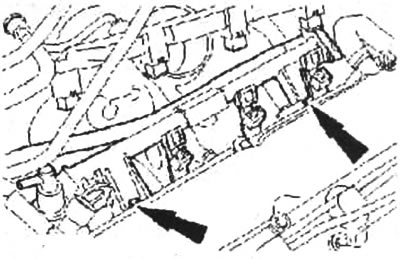

Remove the fuel distributor tube with two screws (arrows) along with injection valves.

Remove the fuel distributor pipe

Remove the connector from the injection valves. The fuel lines remain connected.

Switch the ignition on and off several times to actuate the fuel pump and the fuel system can build up pressure.

Drop test - checking each injection valve

Exactly check all injection valves in turn: only one drop should come out of each valve - if more drips, replace the valve.

If you want to check the injection jet, you must dismantle the entire fuel distribution pipe. Fuel lines remain connected at all valves. Disconnect the connectors on all valves, except for the one being tested, and substitute a container under it.

Turn on the ignition - the valve should inject fuel in a spherical shape.

Repeat the test for each valve.

Visitor comments