Visual inspection of the elements of the fuel injection system

From time to time check the condition and fastening of the following hoses.

1. Vacuum hose connected to the absolute pressure sensor.

2. Vacuum hose connected to the vacuum brake booster.

3. Condition of crankcase ventilation hoses. Make sure the hoses are not clogged, dirty or swollen.

4. Reliability of fastening of fuel lines.

5. Reliability of the connection of the pressure regulator.

6. Fuel return line from the pressure regulator.

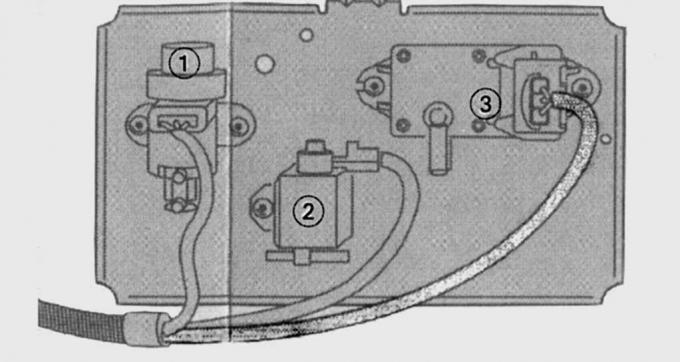

Pic. 8.9. Places for checking the reliability of connecting the contacts of the EVR valve connectors (1), EVAP valve (2) and DPFE sensor (3)

7. When working in the engine compartment, it is necessary to disconnect various connectors, as a result of which the connection of the contacts may be loosened. If this happens, spray the contacts with special contact spray and, if this does not help, be careful to bend the contacts (pic. 8.9).

Determination of the place of depressurization in the air intake system

A leak in the air intake system causes additional air to enter the engine. This interferes with the operation of the control unit and provokes erroneous results, for example, when preparing the fuel mixture: the injectors supply less fuel to the engine, which leads to a lean fuel mixture. This is most clearly determined by the change in the engine speed at idle.

SEQUENCE OF WORK

1. Check vacuum hose for cracks and secure fit. Check the condition and tightness of all hoses that are connected to the throttle assembly and intake manifold (absolute pressure sensor, vacuum brake booster, fuel mixture preparation system, etc.).

2. Start the engine and let it run at idle speed. Open the hood and disconnect the connector from the oxygen sensor.

3. Spray the injection system, all hose connections and gaskets one by one with a standard cold start spray. The place where the engine speed increases when spraying the aerosol is leaking.

Checking the idle speed

The idling speed is constantly adjusted by the control unit and the idling actuator depending on the switched on consumer, for example, headlights, air conditioning or power steering (when turning the steering wheel). The idle speed of the Fiesta gasoline engines is 900 min-1, the diesel engine is 850 min-1. An accurate tachometer or engine tester must be used to check the idle speed. If the idle speed does not meet the required values, it cannot be adjusted separately, it is necessary to determine the violation in the engine. For example, if the wires were disconnected from the battery terminals, the engine control unit needs to spend some time on the road to restore engine control modes.

Visitor comments