Pilot injection provides a gentle rise in combustion pressure as it functions somewhat as a wick for the main injection, which occurs at about 1100 bar. Now the nozzle needle is fully raised in the seat and passes the main amount of fuel through the five nozzle holes from the injection system into the recess of the piston crown. The pre-combustion intensified air vortex captures fresh fuel particles and forms a nearly homogeneous and highly flammable diesel fuel/air mixture.

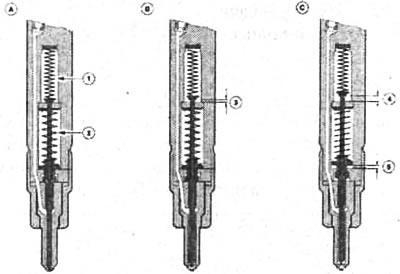

Double injection process: A - the nozzle is closed; B - preliminary injection; C - main injection; 1 - 1st spring; 2 - 2nd spring; 3 - 1st lift; 4 - 1st lift + 2nd lift; 5 - 2nd lift.

The high elasticity of the springs acting on the needles of the injectors does not allow the combustion pressure to kick back into the fuel system. Since all the fuel is never injected, excess fuel is returned - as mentioned at the beginning - through the fuel recirculation line to the fuel tank. The nominal time between the start of injection and the moment of ignition is 0.002 s. It is clear that even the slightest malfunction, such as a scuffed nozzle needle, unbalances a physically balanced combustion process. Unmistakable and audible signs of an out-of-balance diesel engine are loss of power, black smoke or a loud thump (even with warm engines).

Visitor comments