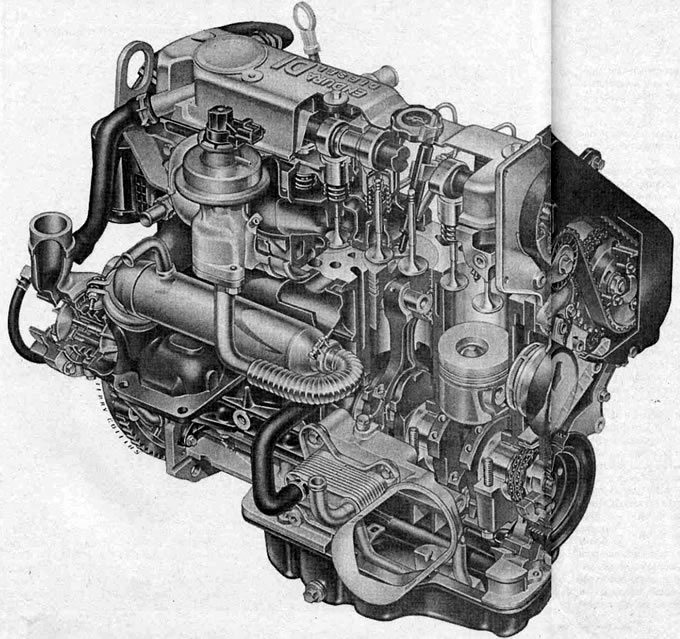

Cross section of the 1.8l TDI engine

The Focus is powered by two compact four-cylinder petrol engines in four different outputs, as well as a two-stage four-cylinder diesel engine with a displacement of 1.8 liters, both diesel engines with exhaust gas turbocharging and direct injection. All engines in the Focus are equally compliant with the EEC-96/D3/D4 exhaust gas standard and other more subjective criteria regarding fuel consumption, quiet operation, «elasticity» and power output required for modern engines.

| Focus - 2000 release | Working volume, cm3 | Power, kW / hp / rpm | Power, Nm/r/min |

| 1.4 L Zetec-SE | 1388 | 55/75/5000 | 123/3500 |

| 1.6L Zetec-SE | 1596 | 74/100/6000 | 145/4000 |

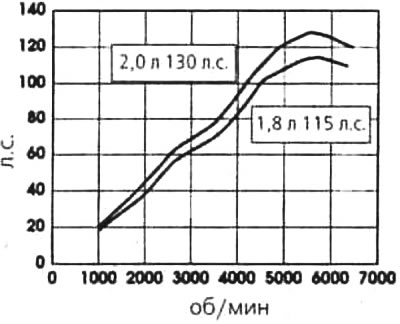

| 1.8 L Zetec-E | 1796 | 85/115/5500 | 160/4400 |

| 2.0 L Zetec-E | 1988 | 96/130/5500 | 178/4500 |

| 1.8 L Endura-Turbodiesel | 1753 | 55/75/4000 | 175/1800 |

The engines in the Focus are controlled by an electronic system (Ford EEC-V), in gasoline engines, it is assisted by a non-contact 3-D ignition system with program control, electronic fuel injection (SEF1) and knock sensors in Zetec-SE engines. Both diesel engines receive fuel directly into the combustion chambers using a single-piston distribution injection pump and double-spring multiport injectors. All petrol engines are equipped with a triple acting variable catalyst, diesel engines with an oxidizing catalytic converter equipped with exhaust gas recirculation.

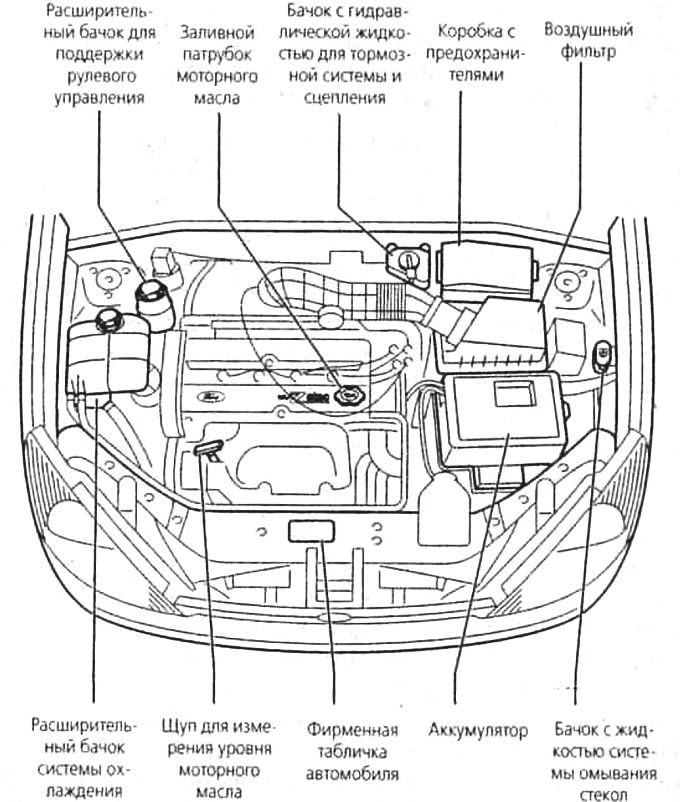

Undeniably compact DOHC engines (dou-blc-ovcrhead-camshaft) Zetec (in Zetec-SE versions engine block and cylinder head made of light metal) are currently a major technical achievement among Ford engines. However, these are the first cross-mounted Ford engines in which the injection line is located on the front side of the cylinder head. This measure significantly improves the accessibility of all elements of the air-fuel mixture preparation during any maintenance work.

At «turn» There are also technical reasons: «turn» head of the cylinder block, the exhaust gas system is no longer in the flow of a cooling headwind, but «hidden» behind the engine. This is very useful for the catalytic converter - it reaches the control temperature even faster. The rearward-sloping mounting position of the engines creates enough room to minimize heat transfer from the exhaust manifold and catalytic converter to the passenger compartment.

Technical Cooperation - Yamaha Involvement

The basic sketch of the Zetec-SE engines came about a long time ago in close collaboration with Yamaha. The first variants have been installed on the Fiesta since 1996. Ford features electronically controlled multi-port injectors in compact four-cylinder engines, sequential fuel injection, and an advanced engine control unit (EEC-V).

Thanks to this, engineers realize even more precise control of the air-fuel mixture and ignition spark.

In practice, these measures lead to reduced friction, more stable idle speed control, lower exhaust emissions and a more even combustion process under all load conditions. Another achievement, including Zetec-E engines, is a balanced filling of cylinders and a rather moderate displacement. The priorities for further development clearly relate to the characteristics of comfort and fuel consumption.

Light metal head to toe - Zetec-SE engines only

The engine block and cylinder head, as well as the housings of most Zetec-SE engine accessories, are made from a special aluminum alloy. This is not the case with Zetec-E engines, their origins are linked to the Endura family.

To reduce weight, the Zetec engine valve covers are made of magnesium and the intake piping is made of synthetic material. Two overhead camshafts rotate in the cylinder heads (DOHC), they operate four valves on each combustion chamber. A number of design measures maintain a high engine culture with low noise and vibration levels, low exhaust gas emissions, as well as pleasantly low maintenance costs. Thanks to more resistant materials, the valves only need to be checked in the workshop every 150,000 km. The valve clearance with a cold engine is 0.17-0.23 mm on all intake valves and 0.27-0.33 on the exhaust valves. Replacement of spark plugs is provided after 60,000 km. replacement of engine oil and oil filter - after 15,000 km of run.

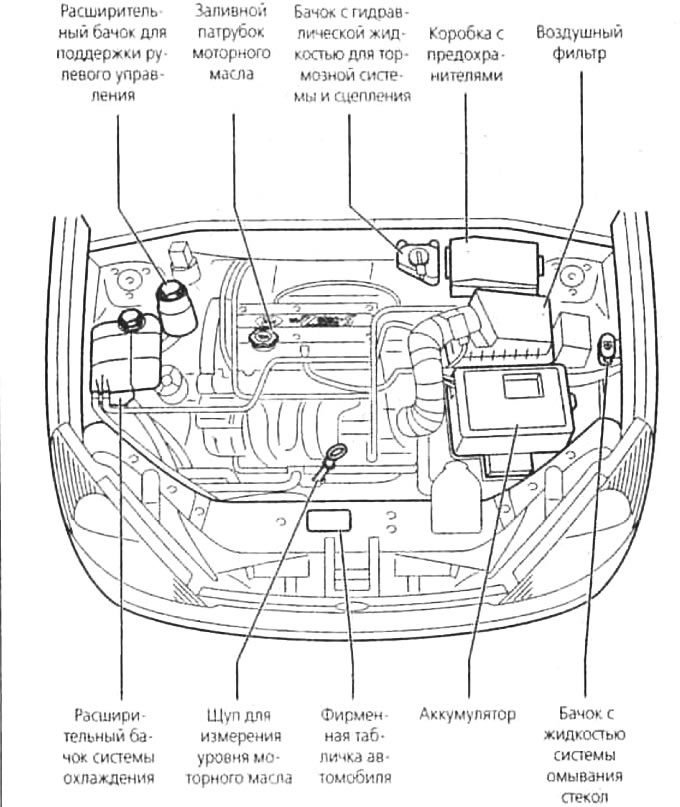

Engine compartment Zetec-SE 16V with a working volume of 1.4 / 1, b l

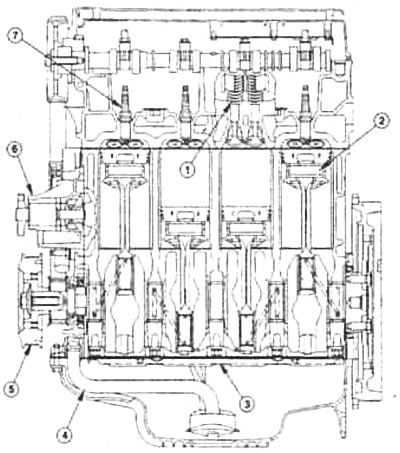

Side view of the Zetec-SE engine: 1 - valve mechanism; 2 - pistons; 3 - oil deflector; 4 - suction oil pipeline; 5 - vibration damper; 6 - water pump; 7 - spark plug.

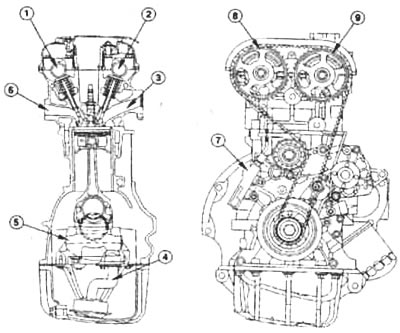

Vertical projection of the Zetec-SE engine: 1 - final camshaft; 2 - intake camshaft; 3 - inlet channel; 4 - suction oil pipeline; 5 - crankshaft; 6 - outlet channel; 7 - hydraulic tensioner of the toothed belt; 8 - exhaust camshaft pulley, 9 - intake camshaft pulley.

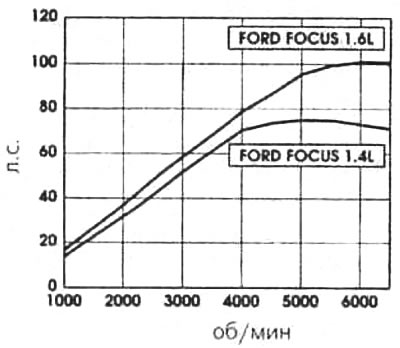

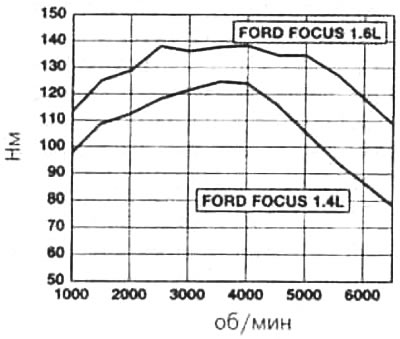

Zetec-SE - operational, «elastic» and moderate fuel consumption engine

Both engines are equally efficient and «elastic» DOHC power plants. The 1.6-liter engine differs from the 1.4-liter model by a modified stroke-to-bore ratio, a camshaft with modified valve timing, and larger valves. In terms of consistently optimizing friction and high performance standards, both engines feature finely drilled gray cast iron cylinder liners cast into a light metal engine block with specially coated lightweight pistons including friction-reduced piston rings. In addition, the accessory drive belt, which is particularly quiet, reduces engine noise and vibration. The oil pump is driven directly by a 5-pin crankshaft: in contrast, the water pump and servo pump, alternator and air conditioner compressor are driven by a maintenance-free drive belt.

Two camshafts rotate in the light metal cylinder head of the Zetec-SE engines. On each cylinder, they operate two intake and two exhaust valves, located at an angle of 42' to each other, with mechanical valve clearance compensation.

The drive provides a reinforced toothed belt with an automatic spring tensioner and mechanical vibration damping.

The owner feels constructive measures not only by ear and visually, but also at the gas station: with an average fuel consumption of 6.4 l / 100 km, Zetec-SE 1.4 l, according to the NEFC standard, burns its super gasoline very moderately. It reaches a top speed of 171 km/h and accelerates in 14.1 seconds from Odo 100 km/h. With a displacement of approximately 200 cm3, the 1.6 liter engine requires 6.8 l/100 km. top speed of 185 km/h and acceleration in 10.9 seconds from 0 to 100 km/h.

Power Chart: Zetec-SE 1.4L/1.6L |

«Elasticity»: Zetec-SE torque curve 1.4L/1.6L |

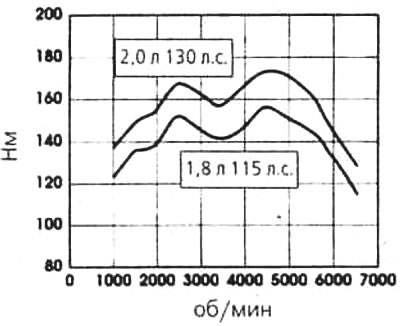

Zetec-E - small differences in detail with big effect

Although the basic design of the Zetec-E engines largely corresponds with its smaller sisters «SE», according to its crank mechanism, it clearly belongs to the Endura family. However, regarding noise «elasticity» and your own friction, you certainly shouldn't be wary of the SE options. Against. Ford only certifies the emissions of E versions in the engine sound area as 5 dB less, «certain» the difference in comfort lies mainly in the invisible details. For example, in a crank mechanism: to minimize the forces of the mass of the second order, the pistons and connecting rods are made in a lightweight design. The engine block is stiffened by reinforced support points and a ladder-type aluminum frame that, as in the 1.4/1.6L engines, is bolted between the engine block and the oil pan.

The 1.8L Zetec-E engine spurs from 0 to 100 km/h in 10.2 seconds, reaching top speed at 198 km/h. In terms of fuel economy, the 1.8L Zetec-E does its job at 7.5L of superpetrol per 100km.

In any case, about a liter less than its brother with a displacement of 2.0 liters. But that «rushes» with a top speed of 201 km/h and accelerates from 0 to 100 km/h in 9.2 seconds.

Engine compartment Zetec-E 16V with a displacement of 1.8 / 2.0 liters

Dual Peak: Zetec-E 1.8/2.0L Engine Torque Curve |

Power Chart: Zetec-E 1.8/2.0L |

Turbocharged diesel engine with direct injection, 55 kW/75 hp. and 66 kW/90 hp

Engine block and crank mechanism in a 1.8L turbocharged diesel engine. Focus replicates key features of 1.8L Endura-DE (44 kW/60 hp) from Fiesta. But the pistons, cylinder head and injection system of the new versions follow the principle of direct fuel injection for the first time at Ford. Ford's first direct-injection diesel engines were already in operation in the early 1980s, powering fast, light-duty vehicles called the Ford Transit.

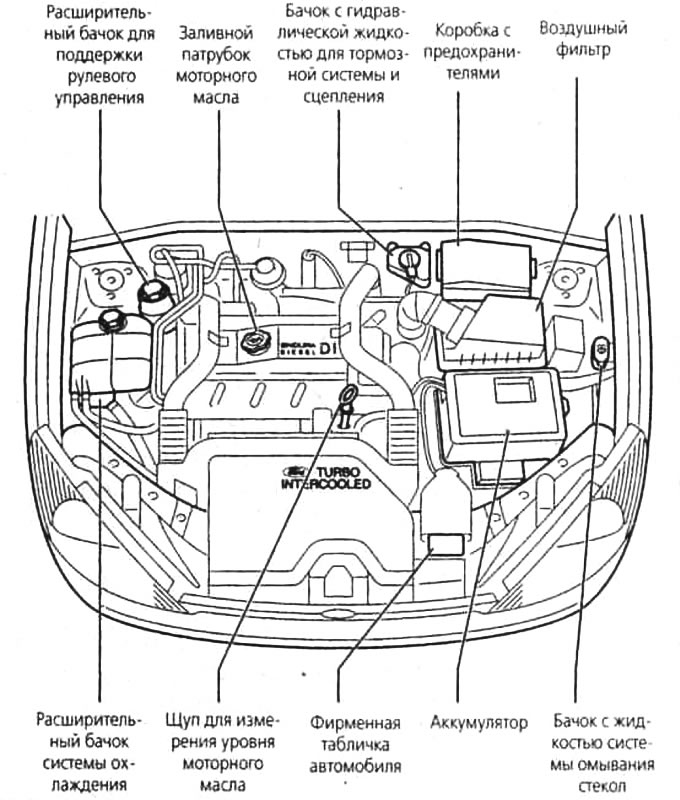

Thanks to exhaust gas recirculation and electronic engine management, the new direct injection diesels are not only among the most economical, but equally among the cleanest members of their guild: they do not even reach the exhaust gas limits planned for new cars since 2001. Both diesel engines are united by a harmonious power characteristic with pronounced efficiency. Technical modifications in the direction of direct injection are largely limited to the cylinder head, a recalibrated and controlled by the Ford EEC-V module single plunger injection pump, dual spring injectors, an oxidation catalytic converter mounted near the engine, a turbocharger integrated in the exhaust manifold and charge air cooler. Exactly «workplace» turbocharger contributes to a spontaneous increase in boost pressure, it almost makes you forget about the often rightfully criticized «turbo failure» in Focus.

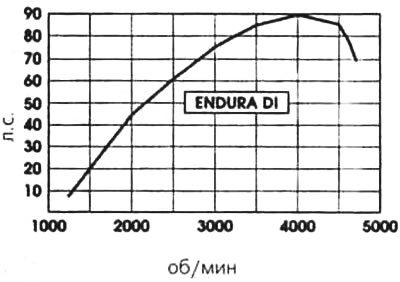

Power chart: Endura DI 66 kW/90 hp |

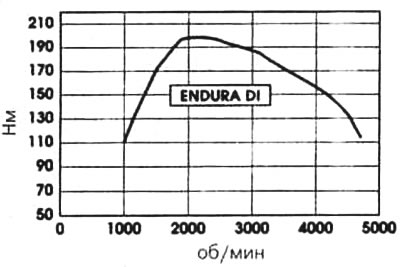

Sustained: Endura DI 66kW/90hp torque curve |

1.8L Endura DI Turbo Diesel Engine Compartment

Expensive measures to reduce vibration and noise make direct injection engines almost «exemplary diesels»

Particular attention has been paid by Ford designers to the characteristics of a comfortable level of vibration of the diesel engine - both in combination with all moving parts of the engine, and with the characteristics of its transmission to the drive and body. Features of the new Endura turbo diesel include, for example, a mechanically decoupled throttle control «Drive-by-wire» (electronic gas pedal).

In addition, high-quality engine mounts, an aluminum ladder frame between the engine block and oil pan, and a high-strength steel crankshaft also help to reduce drive vibration. The sum of the design measures elevates the Endura turbodiesel engine almost to the comfort level of Zetec gasoline engines.

With a displacement of 1753cc3, the Endura turbodiesel has the technical base for adequate power in the upper rev range and power transmission in the midrange. Diesel engine torque curves look nice «flat»: 66 kW/90 hp variant. already slightly above the idle speed, it transmits 110 Nm to the flywheel, a maximum of 200 Nm occurs at about 1000 rpm and drops later after 2000 rpm. 55 kW/75 hp version has a maximum of 175 Nm at 1800 rpm.

In any case, enough for urban traffic and to fly forward quite early in fifth gear on a country road or to move at a maximum speed of 184 km/h (66 kW/90 hp) or 168 km/h (55 kW/75 hp). Turbocharged diesel at 55 kW/75 hp accelerates a sedan with a stepped rear end from 0 to 100 km / h in 14.7 seconds (12.5 s at 66 kW/90 hp). Very attractive driving performance, and with an average fuel consumption of both engines hardly more than 5 liters per 100 km.

Visitor comments