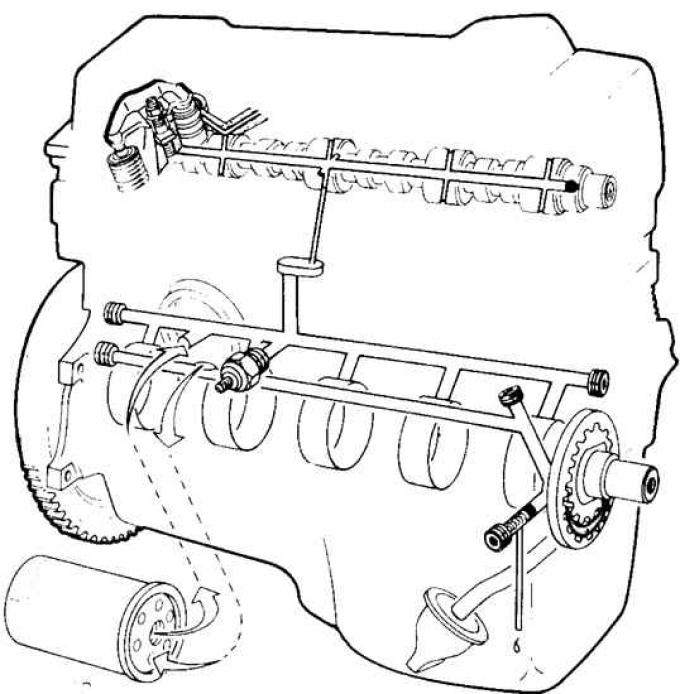

CVH engines

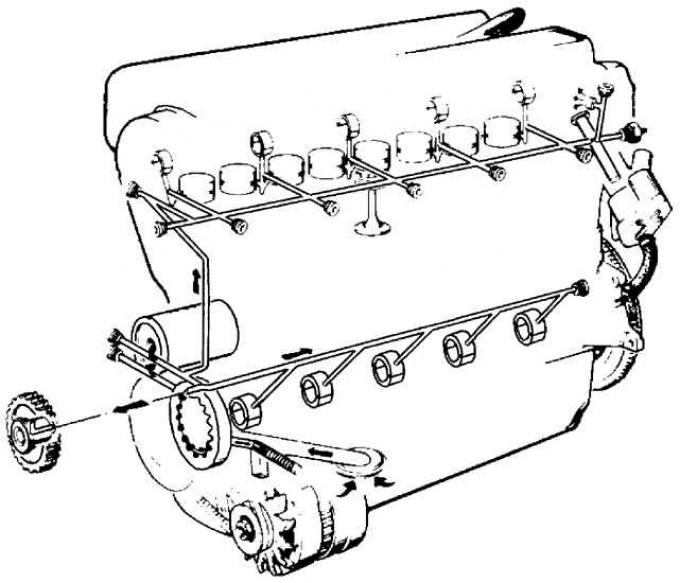

OHV engines

Diesel engines

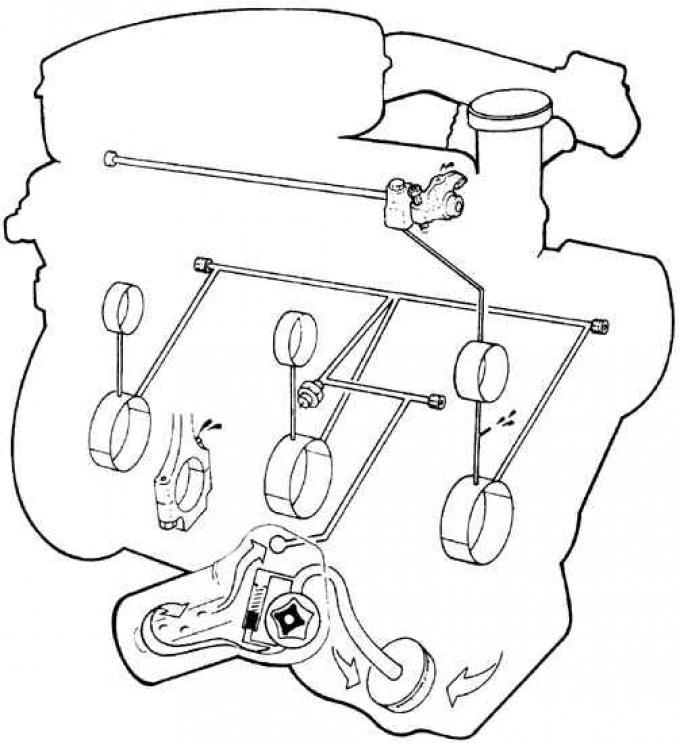

The oil pump pumps engine oil from the oil sump through the oil receiver and supplies it under pressure to the oil filter, and then to the main channel. A pressure reducing valve is located behind the filter, which opens at high oil pressure in the system and the oil flows back into the oil sump. When the oil filter element becomes clogged, the bypass valve opens and allows unfiltered oil to lubricate the engine.

In the CVH engine, oil is supplied from the main channel through five channels to lubricate the crankshaft bearings. Through inclined channels in the crankshaft, oil is supplied to the connecting rod bearings and, being forced out through the gaps in the connecting rod bearings, is sprayed onto the piston pins and cylinder walls.

In OHV engines, the drive chain and gears are lubricated through the sprayer hole in the front inclined tube.

At the same time, through a system of channels, oil is supplied to the cylinder head from the crankshaft main bearings to the camshaft bearing journal and further, through the holes, oil is supplied to the rest of the camshaft bearings.

In the CVH engine, from the camshaft, through the channels, oil enters the hydraulic valve lifters, while the rocker arms and ends of the valve stems are also lubricated through the hole in the pusher piston.

On a diesel engine with a displacement of 1.6 dm3, a non-separable bypass valve is fixed in the supply pipe, which can only be replaced with a pipe.

Visitor comments