Engine crankshaft position sensor installed at the rear of the engine block opposite the flywheel.

If a malfunction occurs in the crankshaft position sensor circuit, the engine stops working, the controller stores the malfunction code in memory and turns on the signal lamp in the instrument cluster. In this case, check that the sensor is working properly.

You will need: socket head «for 8», tester.

1. Disconnect the wire from the terminal «minus» battery.

2. Squeeze the latch..

3.... and disconnect the crankshaft position sensor wiring harness connector.

4. Turn out a bolt of fastening of the gauge …

5.... and remove the sensor from the hole in the cylinder block.

6. Measure the resistance between the sensor leads with a tester. The nominal value of the resistance should be in the range of 0.5–0.6 kOhm. If the resistance is not within the specified limits, replace the sensor.

7. Install the engine crankshaft position sensor in the reverse order of removal.

Camshaft Position Sensors mounted on top of the cylinder head. In the event of a malfunction in the circuit of any sensor, the controller memorizes the malfunction code and uses a bypass engine control program (without changing the valve timing).

You will need a key «on 10».

1. Disconnect the wire from the terminal «minus» battery.

2. Squeeze the latch and disconnect the sensor harness connector.

3. Turn out a bolt of fastening and take out the gauge from an aperture in a head of the block of cylinders.

4. Install the camshaft position sensor in the reverse order of removal.

coolant temperature sensor installed in the outlet pipe of the engine water jacket under the ignition coil.

Check the resistance at the sensor terminals at various temperature conditions.

You will need: key «at 19», tester, thermometer.

1. Disconnect the wire from the terminal «minus» battery.

2. Drain the liquid from the engine cooling system (cm. «Coolant replacement»).

USEFUL ADVICE: When replacing the sensor, the coolant can not be drained: after removing the sensor, plug the hole with your finger or a plug - the loss of coolant will be minimal.

3. Pressing the latch, disconnect the wiring harness block from the sensor, loosen the tightening wrench and unscrew the coolant temperature sensor by hand.

4. Connect the tester to the sensor terminals and measure the resistance, and measure the current temperature with a thermometer.

5. To measure the resistance at the sensor terminals under various temperature conditions, lower the sensor into hot water and check the change in its resistance as the water cools, controlling the water temperature with a thermometer. The nominal resistance of a good sensor is indicated in Table. 10.4.

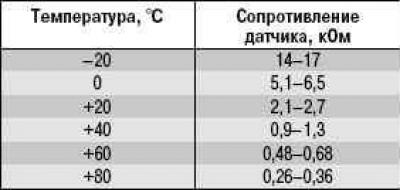

Table 10.4 Data for checking the coolant temperature sensor

6. If the resistance deviates from the norm, replace the sensor.

7. Screw in the coolant temperature sensor and tighten it to 12 Nm.

8. Connect the wiring harness block to the sensor.

9. Fill in coolant.

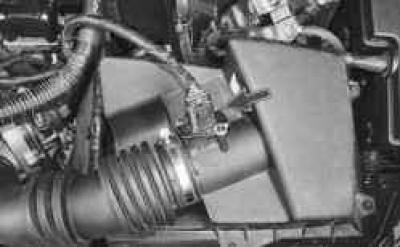

Combined mass flow and intake air temperature sensor mounted on the cover of the air filter housing.

You will need: T20 TORX wrench, flat blade screwdriver, tester, thermometer.

1. Disconnect the wire from the terminal «minus» battery.

2. Use a screwdriver to pry up the sensor harness connector retainer.

3. Squeeze the latch..

4.... and disconnect the wiring harness block from the sensor.

5. Turn out two screws of fastening..

6.... and remove the mass flow and intake air temperature sensor.

7. Connect the tester in ohmmeter mode to the sensor terminals and measure its resistance. Measure the current air temperature with a thermometer and compare the obtained values \u200b\u200bwith the table. 10.5.

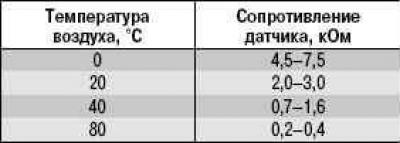

Table 10.5 Mass flow sensor test data and intake air temperature

8. If the resistance deviates from the norm, replace the sensor.

9. Install the combined mass flow and intake air temperature sensor in the reverse order of removal.

NOTE: Install the sensor in such a way that the arrow on the housing matches the direction of air flow.

Throttle position sensoris a variable resistor that is installed on the throttle axis. The rotation of the damper axis causes a change in the voltage of the sensor signal, by which the controller determines the degree of throttle opening. The sensor is built into the throttle assembly cover, so if the sensor fails, replace the throttle assembly assembly (cm. «Removal and installation of the throttle assembly»).

Vehicle speed sensor mounted on the gearbox near the right front wheel drive.

You will need a flat blade screwdriver.

1. Disconnect the wire from the terminal «minus» battery.

2. Lift up the speed sensor harness heat shield.

3. Squeeze the latch and disconnect the wiring harness block from the speed sensor.

NOTE: For clarity, the following operations are shown with the gearbox removed.

4. Using a screwdriver, remove the tab of the locking pin from the recess in the gearbox housing..

5.... and remove the locking pin.

6. Remove the speed sensor from the hole in the gearbox housing.

7. Inspect the sensor o-ring. In case of any damage, as well as if there are traces of oil on the gearbox housing around the sensor, it is necessary to replace the ring with a new one.

8. Install the speed sensor in the reverse order of removal.

Oxygen concentration sensors installed on the collector before and after the converters.

Oxygen concentration sensors at the inlet to the converters - control..

... at the outlet of the neutralizers - diagnostic.

All four sensors have the same parameters and differ only in the length of the wires. If at least one of the oxygen concentration sensors is faulty, the toxicity of the exhaust gases can increase dramatically, and fuel consumption will increase.

For ease of replacement, the sensors differ in the color of the wires and their pads. The left converter sensors have blue wires and the right converter sensors have white wires. Blocks of wiring harnesses of sensors at the inlet to the converters (managers) green, and at the outlet of the neutralizers (diagnostic) - blue.

You will need a key «at 22».

1. Disconnect the wire from the terminal «minus» battery.

2. Squeeze the latch..

3.... and disconnect the wiring harness block of the sensor being replaced.

4. At the diagnostic sensor, remove the wiring harness from the holder on the thermal screen.

5. Turn out the control..

6.... or diagnostic sensor..

7.... and remove it from the opening of the collector.

8. Install the oxygen concentration sensor in the reverse order of removal.

NOTE: A failed oxygen sensor can be replaced with a sensor with a longer wiring harness. In this case, it is necessary to fix the harness in such a way as to avoid its contact with hot parts of the exhaust system.

knock sensors screwed into the wall of the cylinder block in its upper part, under the intake manifold in the areas between the 1st and 2nd, as well as between the 3rd and 4th cylinders.

You will need a key «at 13».

1. Disconnect the wire from the terminal «minus» battery.

2. Disconnect the wiring harness connector of the sensor being replaced.

3. Turn out a bolt of fastening of the gauge of a detonation and remove the gauge.

4. Install the sensor in the reverse order of removal.

Visitor comments