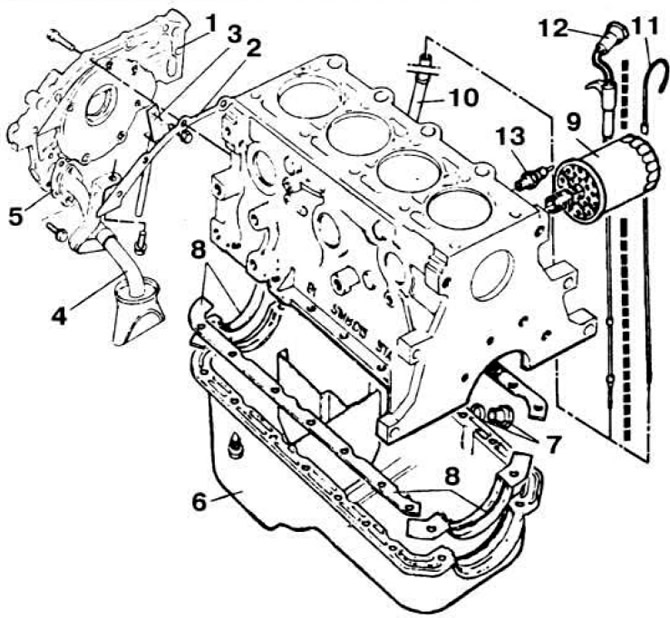

Pic. 2.70. Parts of the engine lubrication system, except for the GLA model.

Pic. 2.70. Parts of the engine lubrication system, except for the GLA model.

1 - oil pump: 2 - gasket; 3 - oil drain pipe; 4 - oil injection tube; 5 - gasket for the flange of the oil injection pipe; 6 - oil sump; 7 - drain plug with gasket; 8 - oil crankcase seal; 9 - oil filter; 10 - oil dipstick tube; 11 - oil dipstick; 12 - oil dipstick with level indicator; 13 - emergency oil pressure sensor.

The gear oil pump, with gears of internal, trochoidal engagement, is mounted on the front end of the cylinder block. The drive gear of the pump is installed on the front end of the crankshaft. Oil pressure at its temperature of 80°C: at a crankshaft speed of 750 rpm - 1.0 kgf / cm2; at a crankshaft speed of 2000 rpm - 2.8 kgf / cm2. The oil filter is replaceable, full-tray brand Motorcraft Super EFL 134. The emergency oil pressure sensor turns on a red signal lamp on the instrument panel at an oil pressure of 0.3-0.5 kgf / cm2.

On a car model XR3 of release since July 1982, the amount of oil washed down in the system has been reduced to 3.5 liters with a filter change and to 3.25 liters without a filter change. Since December 1982, the same amount of oil has been added to other models. If the engine has a green oil dipstick, then the engine is equipped with an emergency oil level sensor; if the dipstick is white, then such a sensor is not installed. For engines that do not have such dipsticks, the amount of oil in the system remains the same (tab. 1.8). Since April 1983, for engines with injection, the use of synthetic oils Mobil 1, Veedol-Huile synthetique, Castrol TXT and Castrol formule RS has been allowed with replacement every 10,000 km.

Removal and installation of an oil crankcase

Disconnect the negative cable from the battery and drain the oil from the lubrication system. Disconnect the wires from the starter and remove it. unscrewing the three fixing screws. Remove the clutch housing cover. Loosen the oil sump bolts and by sliding it to the side with a screwdriver, remove it. Before installing the oil sump, thoroughly clean its mating surfaces. Install new rubber seals in the annular grooves of the rear bearing and oil pump housing, and fix the cork gasket to the cylinder block with grease. Install the oil sump and tighten the fastening bolts in two steps to a torque of 0.8-1.1 kgf·m. Screw in the drain plug. Install the clutch housing cover. Install starter and connect electrical wires. Fill the lubrication system with oil and connect the negative cable to the battery.

Removal and installation of the oil pump

Drain the oil from the lubrication system. Remove the toothed belt guard and toothed belt. Remove the crankshaft sprocket and oil pan. Remove oil pump. Before installing, clean the oil sump and oil receiver. Install the oil pump in the reverse order of removal.

Visitor comments