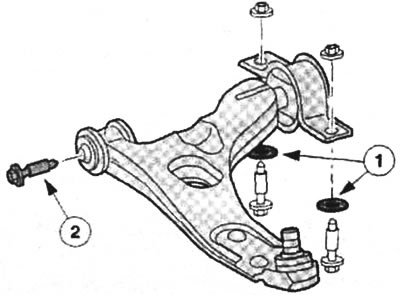

Wishbone: 1 - nested washers; 2 - captive screw.

Stages of work

Turn the steering wheel all the way.

Check the ball joints on the right and left for external damage. At the same time, attach the mounting lever and check the gap.

Check both bearings in the same way. Remember that bearings must initially have a certain elasticity. If only the mounting arm turns without resistance, the bearings are worn.

Experienced amateur mechanics, equipped with the right equipment, will want to take on the job themselves. However, we do not advise you to do this, since the work is not only to replace the bearing or ball joint: instead, you must dismantle the control arm assembly and re-measure the front axle after the repair is completed. In a specialized workshop, this will be done better.

Visitor comments