Safety instructions: When working under the vehicle, it must, if it is not on a lift, stand on secure jack stands. Under no circumstances should work be carried out under the vehicle if the stands are not sufficiently secure or if the vehicle is only supported by a jack. Life threatening!

The car should only be lifted empty.

Wheels that remain on their buttocks when the vehicle is lifted must always be secured against rolling back and forth with wedges.

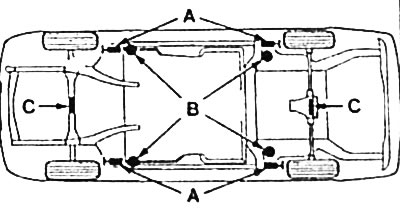

Lifting points

A: lifting points with side jack

B: lifting points with a lifting platform or for cradles

C: lifting points with a garage jack

Lifting with a garage jack

Attention: Be sure to use suitable rubber or wooden spacers to avoid deformation of the body when lifting the vehicle.

Front end

Raise the car from the front by the central part of the front axle beam.

Support the vehicle with jack stands.

Rear end

Raise the car from behind by the central part of the cross member.

Support the vehicle with jack stands.

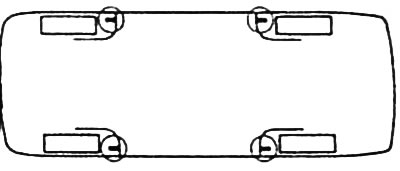

Supporting the car with jack stands

Attention: Before working under the vehicle, always support it with jack stands. The use of suitable rubber or wooden spacers will prevent damage to the bodywork when supported by jack stands.

Front end

Support the car on both sides of the frame.

Rear end

Support the car on both sides of the frame.

Lifting points with onboard jack

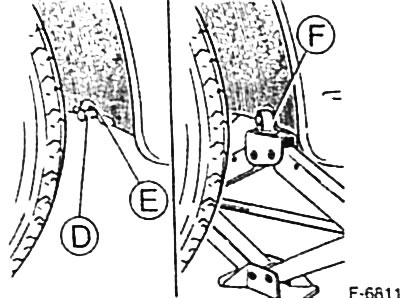

The guide pins for the board jack are located in the wheel arches.

Clean the guide pins from dirt.

Vehicles up to 1/92: Push jack head -F- fully onto corresponding guide pin -D-. Attach the jack as shown in the figure, while the corbel -E- on the channel must coincide with the groove of the jack.

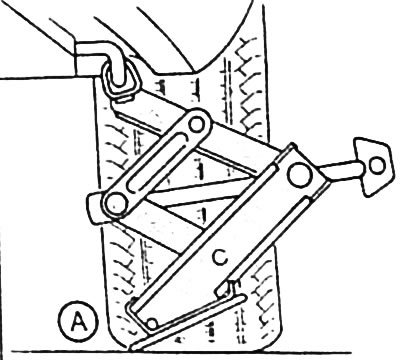

Vehicles from 2/92: Position the jack so that its bearing surface -A- is at an angle as shown in the illustration. Push the head of the jack all the way onto the appropriate guide pin. Attach the crank and, rotating it, raise the car. In this case, the jack is straightened, and its supporting surface comes into contact with the floor over the entire area.

Attention: In no case should the car be lifted by the ends of the guide pins, because. they may bend and the vehicle may slip off the jack. Therefore, it is always necessary to ensure that the head of the jack is pulled over the trunnion to failure.

Lock wheels that remain on the floor when the vehicle is lifted against rolling forwards and backwards using wedges. Do not rely on the parking brake, which must be released for some repairs.

Raise the vehicle only on level, firm ground.

Caution: If the vehicle is to be lifted high on soft ground, wide boards must be placed under the jack and jack stands to spread the weight over the increased area.

Support the car with jack stands so that one leg on the side is turned outward as needed.

Caution: Never lift or support the vehicle through the engine or gearbox. Never start the engine with a raised vehicle and do not shift into gear while at least one drive wheel is touching the base plate.

Visitor comments