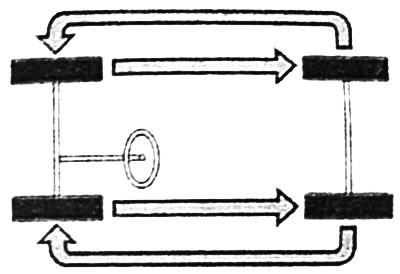

In case of clearly pronounced strong wear of the front tires, it is recommended to swap the front wheels with the rear ones. As a result, all 4 wheels will have approximately the same service life.

Safety note: Do not change tires individually, in extreme cases, replace both tires of one axle at the same time. Tires with a deeper tread pattern should always be fitted to the front axle. Only use tires of the same size and the same design on the front and rear axles, and if possible from the same manufacturer and with the same tread pattern.

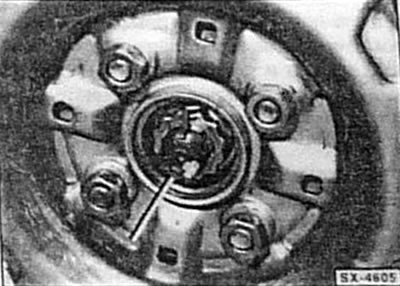

Before removing the wheel, mark its position on the hub with chalk or a felt-tip pen. This will allow you to install the wheel in its original position during installation.

Loosen the wheel nuts only when the vehicle is on wheels. Before loosening the nuts, apply the handbrake or engage 1st gear so that the vehicle cannot move.

Attention: Light alloy rims are protected against corrosion by clear varnish. When changing wheels, take care not to damage the protective layer, otherwise the protective coating must be restored.

To protect against deep corrosion, the landing site of the disk wheel, both front and rear, must be lightly treated with grease for rolling bearings each time the corresponding wheel is removed.

Clean dirty wheel nuts and threads. Do not lubricate the nut threads.

Tighten the wheel nuts in a crosswise manner in several steps. A torque wrench must always be used to tighten the wheel nuts. This ensures that the wheel nuts are evenly and firmly tightened. The tightening torque for all wheel nuts is 100 Nm.

Attention: If the wheel nuts are tightened one-sidedly or unevenly, increased stresses can occur in the wheel and/or wheel hub.

Wheel balancing

Commercial wheels are balanced at the factory Balancing is necessary to compensate for uneven weight distribution and wheel material inaccuracies.

In operation, the imbalance becomes noticeable due to the occurrence of vibrations and angular oscillations of the vehicle axle in the transverse plane. At the same time, the steering wheel begins to tremble at high speeds.

As a rule, the vibration appears in a certain range of driving speed and stops again at a lower or higher vehicle speed. Such unbalance phenomena over time can lead to damage to the suspension joints, steering gear and shock absorbers.

The wheels must be balanced after each repair of tires, since as a result of wear and after repair, the distribution of masses and material changes, which causes a division of the unbalance.

Visitor comments