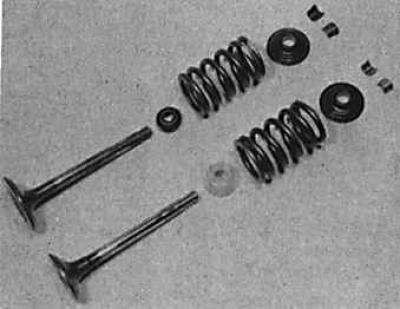

Intake kit (up) and exhaust valves

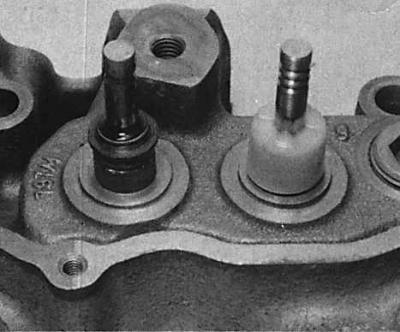

Intake seal (left) and exhaust valves

1. Remove oil and dirt from cylinder heads. Remove carbon deposits from combustion chambers and valve heads with a scraper or a rotating wire brush.

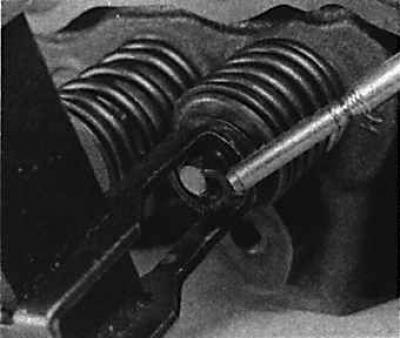

2. Compress the valve springs with a suitable valve spring compressor and remove the valve cotters. Remove the valve spring compressor and remove the valve spring cup, spring and valve. Mark each valve so that you can reinstall it later.

3. After removing the valves, remove carbon deposits from the walls of the channels.

4. Check valve discs and seats for chipping and burning. Slight chipping on the valve and valve seat can be removed by lapping first with a coarse grinding paste and then with a fine grinding paste. For deep chipping, the valves must be ground on a valve grinding machine and the seats on a valve seat milling machine. For the last two types of work, you need to contact specialists.

5. Check the valve guides for wear: insert the valve into the guide, the valve in the guide should move easily, without side play. To replace worn guides with new ones, special tools are required, so you need to contact specialists.

6. The valves should be lapped using only fine-grained polishing paste.

7. Lubricate the surface of the valve seat with a small amount of paste and install the valve in the appropriate seat. Firmly press the rubber suction cup against the valve plate and rotate the valve in one direction or the other.

8. After the end of the lapping process, thoroughly clean all parts from dirt and paste and check the valve seat and disc. A solid opaque ring should be visible on both parts, which indicates the width of the valve chamfer.

9. Check valve springs for compression force and unloaded spring length.

10. Lubricate the valve stem with engine oil and install in the valve guide. Install new seal.

11. Install the valve spring and valve spring cap.

12. Using an appropriate valve spring compressor, compress the spring so that the cotters are seated in the grooves in the valve stem. Remove fixture.

13. After installing all the parts in place, lightly tap with a plastic-faced hammer on top of the valve springs to make sure that the cotters are in place.

Visitor comments