| Name | Specification |

| Rear side panel | |

| Seal mounting panel |

Withdrawal

1. General notes:

- Sectional replacement of the rear side panel is also possible depending on the nature of the damage (see operation no. 44 512 0).

- Remove the following items: bumper, tail light, tailgate seal, vent holder, filler cap, fuel filler, door window, interior trim panels, inner fender, seat cushion, rear seatback, seat belt, roof lining, roof beam protective trim, bottom trim panel trim and lock counterpart.

- Move flooring and electrical wiring away from work area.

- Notice the replacement rear side panel cutout in conjunction with the bottom trim panel.

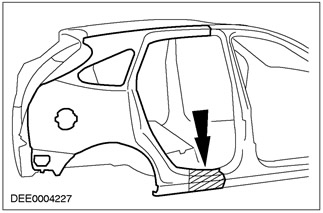

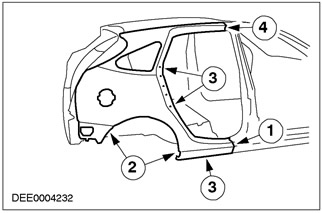

2. Rear side panel

- cutting zone.

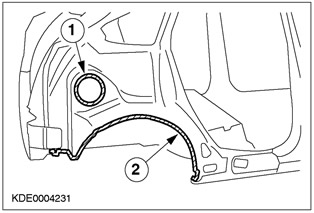

3.

CAUTION: For reasons of welding technology (2-layer panels) ensure the cut size is accurate.

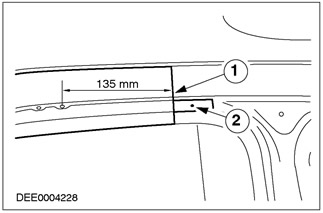

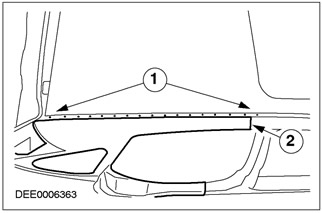

Rack "IN" - roof beam

- 1. Res (base for size - hole center).

- 2. Mill out the spot welds, remove the seal mounting panel.

4.

CAUTION: Roof panel: Only cut to a depth equal to twice the thickness of the panel. To remove the remaining flange, make a cut along the roof panel (better access).

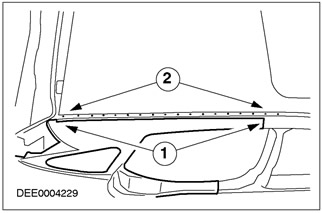

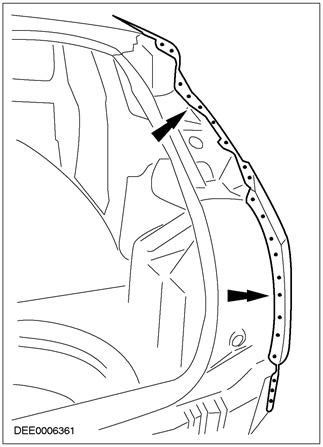

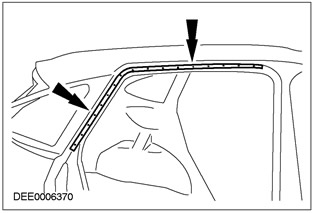

Rear side panel/roof connection

- 1. Cut.

- 2. Mill out the spot welds. Use a spot weld cutter with a diameter of 7 mm. In the area where the roof beam/rear side panel joins, cut out two more spot welds. Be careful not to damage the reinforcement panels below.

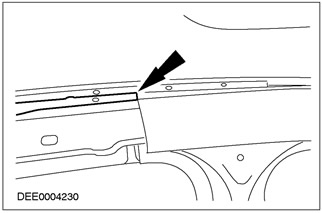

5. Rear side panel/roof connection

- Place of cut

- Raise the roof panel slightly using the plastic wedge.

- Saw the remaining joint in the roof joist.

- Remove the remaining flange.

Installation

1.

NOTE: Apply flange protector and two-component metal adhesive immediately before installing a new replacement part.

Sealing

- 1. Apply flange sealant.

- 2. Apply two component metal adhesive.

2. Rear side panel

- 1. Using spot welding, weld the backing strip along the cut edge and make a continuous MIG weld.

- 2. Crimp the connection of the wheel arch sections and spot weld.

- 3. Perform a puddling weld.

- 4. Make a continuous MIG weld.

3. Rear Side Panel - Rack "D"

- Perform a puddling weld.

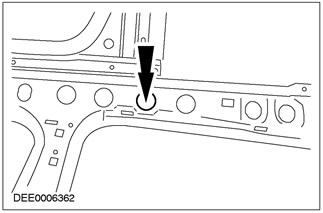

4. Rear side panel - roof beam

- The welding area of the rear side panel connection flange is on the inside. Run a continuous MIG weld through the hole in the roof joist.

5. Rear side panel/roof connection

- To connect the roof beam, drill out the weld flange in the rear side panel/roof connection only to a diameter of 5 mm. Use existing holes.

- 1. Perform a puddling weld.

- 2. Make a continuous MIG weld.

6. Seal mounting panel

- Install the mounting plate in the same position as "old" panel and puddling.

7. Sealing - corrosion protection

- Apply flange sealant to the roof/rear side panel joint to a thickness that allows the protective strip to remain at its original height and fit accurately.

Visitor comments