Disassembly

1. Remove the oil supply and return lines from the hydraulic booster. Seal the ends of the pipelines with plugs.

2. Disconnect the ball joints from the tie rods after loosening the locknuts.

3. Remove the casing clamps and the protective casing from the transmission housing.

4. Move the rack from stop to stop to remove oil remaining in the hydraulic booster.

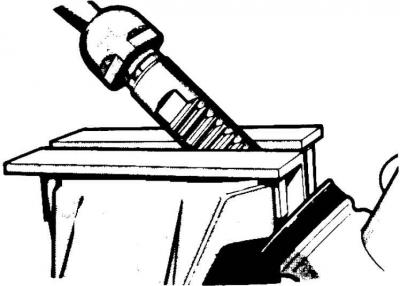

5. Move the rack to the end position and clamp the rack (for the teeth) in a vice.

6. Remove the tie rod retainers and disconnect the tie rods from the gear train.

7. Unscrew the pusher cover bolts, remove the cover, remove the shims, spring and pusher.

8. Remove the bottom plug from the steering gear housing.

9. Loosen the steering gear lock nut.

10. Mark the position of the drive gear corresponding to the forward movement, as well as the protrusion of the rack on both sides of the housing.

11. Remove the steering gear cover and bearing circlip.

12. Remove the steering gear from the housing together with the bearing.

13. Rotate the right bearing race until the retaining ring appears at the end of the housing.

14. Remove the toothed rack circlip.

15. Remove the rack, support sleeve, bearing and gasket.

Checking the rack

1. Check the condition of interacting surfaces:

- O-ring with steering gear drive shaft;

- teeth of the rack and pinion, as well as the working surface of the pusher;

- Teflon seal for the steering gear split valve.

2. Check and flush hydraulic lines and channels:

- pipeline and bypass channel (by-pass) in the gear rack housing;

- separating valve.

3. Replace worn or damaged parts and lubricate O-ring lips with Calipsol grease.

Attention! The Teflon ring of the separation valve fitting must be immersed in boiling water immediately before installation so that it can be properly positioned.

Attention! The steering gear and splitter valve come in pairs and must be replaced together.

Assembly

1. Install a new drive gear gasket in the housing, as well as a new ring (with tool 13.010). The tool hole cavity must be at the height of the upper plane of the drive gear housing.

2. Insert the nylon spacer and the rack seal using a bushing of the correct diameter.

3. Lubricate the gear rack with 40 grams of grease.

4. Install the toothed rack with bearing and support sleeve in the housing.

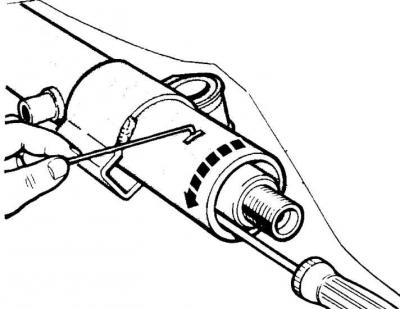

5. Install a new circlip through the hole in the housing. Fasten its hook to the support sleeve.

6. Install the gear rack in the middle position and fix it in accordance with the designations made during the disassembly of the transmission.

7. Secure the bearing and sealing ring longitudinally with a circlip.

8. Install bearing housing filled with solid lubricant.

9. Screw the locknut onto the bottom of the steering gear.

10. Position the tappet in the rack housing.

11. Position the indicator in the bracket (15.046 and 15.009) on the marking plate. Set the indicator needle to zero.

12. Install the indicator on the pusher, and its measuring tip on the body. Record maximum reading (A) indicator when moving the gear rack from one extreme position to another.

13. Thickness (E) shims, which should be installed under the pusher cover, is equal to the measured value (A) increased by the maximum structural clearance (F): E = A F, where F = 0.125 mm.

14. Install the pusher spring, gap adjusting shims, gasket and screw on the cover.

15. Move the gear rack to its end position and clamp it in a vise.

16. Connect the tie rods to the rack and install new tie rod retainers.

17. Install the rubber protective covers and fix them with new fastening clamps.

18. Connect the ends with ball joints to the steering rods and secure them against unscrewing with locknuts.

Visitor comments