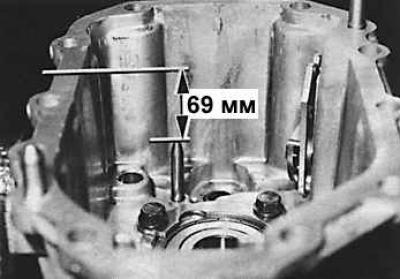

The control dimension of the position of the end face of the selector

1. Using an inertial puller, remove the bearing (3) (see fig. Shafts and gears of a mechanical gearbox type MT 75) output shaft from the gearbox housing.

2. Remove the output shaft bearing mounting plate from the gearbox housing.

3. Using a bushing of the appropriate diameter, knock out the ball bearing of the secondary shaft into the gearbox housing.

4. Remove the 1st-2nd gear fork shaft from the gearbox housing.

5. Remove the O-ring from the selector shaft.

6. Using a bushing of the appropriate diameter, remove the selector shaft needle bearing from the gearbox housing.

Attention! In case of replacement of the gearbox housing, the selector should be positioned so that the distance between its end face and the plane of the housing is 69 mm (see fig. The control dimension of the position of the end face of the selector).

7. Using a rod of the appropriate diameter, install a new needle bearing on the selector main shaft from inside the gearbox housing.

8. Install a new O-ring on the main selector shaft in the gearbox housing.

9. Position the selector shaft in the gearbox housing so that its rolled part is directed towards the crankcase sealing plane.

10. Using a suitable pin, press the intermediate shaft needle bearing into the gearbox housing as far as it will go.

11. Using a suitable pin, press the ball bearing of the output shaft into the gearbox housing as far as it will go.

12. In the gearbox housing, install the output shaft bearing mounting plate and tighten the bolts to the appropriate torque.

13. Using a bushing of the appropriate size, remove the ball bearing from the input shaft towards the front of the clutch housing.

14. Remove the needle bearing retaining ring.

15. Using a bushing and a wooden mallet, drive the bearing off the intermediate shaft towards the rear of the clutch housing.

16. Using a puller, remove the selector shaft needle bearing from the clutch housing.

17. Insert the intermediate shaft bearing into the clutch housing using a rod. The bearing should not be installed all the way, it is necessary to leave a distance of 2 mm from the plane of the clutch housing flange.

18. Install a new ball bearing retaining ring.

19. Using a bushing, install a new input shaft bearing into the clutch housing.

Visitor comments