| PROCEDURE | ||

|

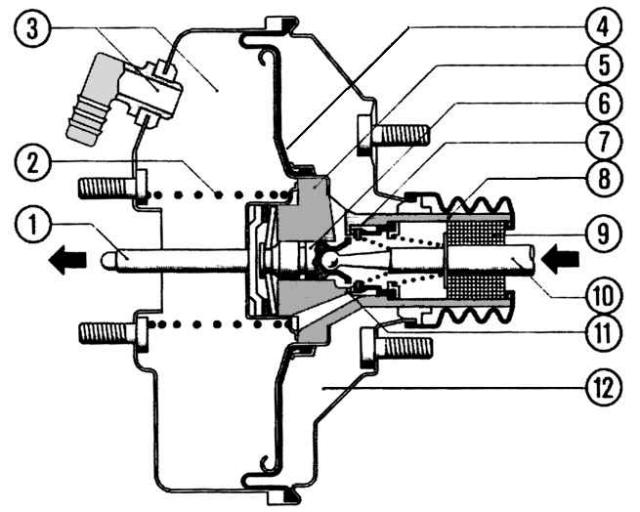

Checking the brake booster

This article is available at russian, bulgarian, belarusian, ukrainian, serbian, croatian, romanian, polish, slovak, hungarian

Next articles »

Functional check of the brakes

Measuring Disc Brake Pad Wear

Checking Disc Brake Wear

Bleeding the brake system

Brake Fluid Replacement

Dismantling the compensation tank of the main brake cylinder

Dismantling and installation of the main brake cylinder

Dismantling and installation of the brake booster

Dismantling and installation of brake hoses

Replacing disc brake pads

Functional check of the brakes

Measuring Disc Brake Pad Wear

Checking Disc Brake Wear

Bleeding the brake system

Brake Fluid Replacement

Dismantling the compensation tank of the main brake cylinder

Dismantling and installation of the main brake cylinder

Dismantling and installation of the brake booster

Dismantling and installation of brake hoses

Replacing disc brake pads

See other similar articles for Ford cars:

• Checking the operation of the vacuum brake booster Ford Focus 2 (2004-2010)

• Checking the brake fluid level Ford Escort 5 (1990-1997)

• Checking the vacuum brake booster Ford Fiesta 4 (1996-1999)

• Brake booster — removal, installation and adjustment Ford Taurus 1 and 2 (1986-1994)

• Checking the operation of the vacuum brake booster Ford Fusion (2002-2012)

• Checking the operation of the vacuum brake booster Ford Focus 2 (2004-2010)

• Checking the brake fluid level Ford Escort 5 (1990-1997)

• Checking the vacuum brake booster Ford Fiesta 4 (1996-1999)

• Brake booster — removal, installation and adjustment Ford Taurus 1 and 2 (1986-1994)

• Checking the operation of the vacuum brake booster Ford Fusion (2002-2012)

Link to this page in different formats

HTMLTextBB Code

No comments yet

Mondeo 4

Mondeo 3

Mondeo 2

Mondeo 1 and 2

Mondeo 1

- General information

- User guide

- Power unit

- Engine repair

- Lubrication system

- Cooling system

- Exhaust system

- Supply system

- Fuel vapor recovery

- Transmission

- Clutch

- Car gearbox

- Wheel drives

- Chassis

- Front suspension

- Rear suspension

- Steering

- Brake system

- Body

- Exterior

- Interior

- Doors, locks and windows

- Heating and ventilation

- Security systems

- Electrical equipment

- Electrical appliances

- Headlights and lighting

- Battery and alternator

Mondeo 3

- General information

- Introduction to the guide

- Workplace equipment

- Car care

- Help with malfunctions

- Power unit

- Engine repair

- Lubrication system

- Cooling system

- Fuel injection system

- Ignition system

- Fuel system

- Transmission

- Chassis

- Chassis

- Brake system

- Body

- Interior

- Exterior

- Electrical equipment

- Light and appliances

- Battery and alternator

- Schematic diagrams

Mondeo 2

- General information

- User guide

- Maintenance and care

- Wheels and rims

- Power unit

- V16 engine

- Duratec VE

- Lubrication system

- Cooling system

- Power systems

- Ignition system

- Exhaust system

- Transmission

- Clutch

- Mechanical gearbox

- Automatic gearbox

- Wheel drives

- Chassis

- Front suspension

- Rear suspension (sedan)

- Rear suspension

- Steering

- Brake system

- Brake service

- Electrical equipment

- Battery and alternator

- Light and appliances

Mondeo 1 and 2

- General information

- User guide

- Vehicle data

- Repair on the road

- Weekly checks

- Periodic maintenance

- Troubleshooting

- Engine

- 4 cylinder engines

- 6 cylinder engines

- Removal and repair

- Cooling system

- Fuel/exhaust systems

- Emission management

- Starting and charging systems

- Ignition system

- Transmission

- Clutch

- Mechanical gearbox

- Automatic gearbox

- Drive shafts

- Chassis

- Brake system

- Suspension

- Steering

- Body

- Exterior

- Interior

- Electrical equipment

Mondeo 1

- General information

- Car care

- Maintenance

- Troubleshooting

- Power unit

- Engine repair

- Cooling and lubrication system

- Ignition system

- Fuel/exhaust systems

- Fuel injection (gasoline)

- Fuel injection (diesel)

- Transmission

- Clutch and drive shafts

- Car gearbox

- Chassis

- Suspension

- Steering

- Brake system

- Wheels and tires

- Body

- Exterior

- Interior

- Doors, locks and windows

- Heating system

- Electrical equipment

- Equipment and devices

- Power devices

- Lighting and signaling

- Windshield wipers and washers

- Electrical circuits

FordBook.ru © 2014-2024 • Mobile version • Interesting to read • Sitemap: EN BG BY UA RS HR RO PL SK HU • Site search • Contact with administration

Focus 1 • Focus Turnier 1 • Focus 2 • Mondeo 1 • Mondeo 1 and 2 • Mondeo 2 • Mondeo 3 • Mondeo 4 • Escort 3 • Escort 4 • Escort 5 • Fiesta 2 • Fiesta 4 • Taurus 1 and 2 • Fusion • Scorpio 1 • Scorpio 2 • Sierra •

Focus 1 • Focus Turnier 1 • Focus 2 • Mondeo 1 • Mondeo 1 and 2 • Mondeo 2 • Mondeo 3 • Mondeo 4 • Escort 3 • Escort 4 • Escort 5 • Fiesta 2 • Fiesta 4 • Taurus 1 and 2 • Fusion • Scorpio 1 • Scorpio 2 • Sierra •

Visitor comments