The following description assumes that the drive shafts have already been removed.

Removing the protective collar of the internal drive joint

Tighten the drive shaft into a vise (use protective cheeks).

Disconnect the tension straps with a side cutter and discard. Move the cuff.

Extend the tripod hinge.

Open the sprocket safety ring; remove the sprocket with a claw puller.

Remove cuff; dispose of the lubricant.

Mounting the protective collar of the internal drive joint

Pull on the cuff; insert the tension band into the annular groove and tighten.

Push the tripod sprocket onto the drive shaft until it stops with a suitable punch or special tool (do not damage the timing rollers).

Secure the tripod sprocket with a new retaining ring.

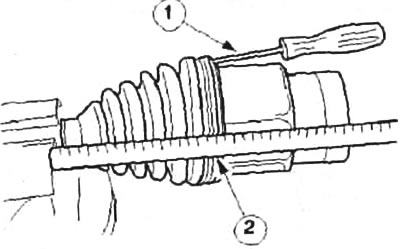

Fill the joint with grease (for quantity of grease, see section «Checking the cuffs of the drive shafts»). Insert a small screwdriver 1 under the cuff to remove air.

«Adjustment» hinge

Push the tripod hinge in until it stops, then pull out 2 x 20mm.

Take out the screwdriver.

Insert the tension band into the annular groove and tighten.

Removing the protective collar of the external drive joint

Disconnect the tension straps with a side cutter and discard.

Remove the cuff from the side of the gearbox.

Dispose of the lubricant filler.

Mounting the protective collar of the external drive joint

Always use new safety rings and tension collars.

Slide on the cuff from the side of the gearbox.

Secure the end of the cuff on the side of the wheel with a tension band.

Fill the drive joint with grease (for quantity of grease, see section «Checking the cuffs of the drive shafts»).

Press the cuff into the annular groove of the drive joint. To allow air to escape, insert a small screwdriver under the cuff.

Insert the tension tape into the annular groove of the cuff and tighten.

Fine «rinse» lubricant

Before you finally fix the tension collars, flush out the new grease well. To do this, rinse the folded roller and carefully turn the hinge at the same time: then the lubricant is evenly distributed in the cuff and in the hinge. Make sure that the cuff sits on the drive shaft without squeezing folds.

Visitor comments