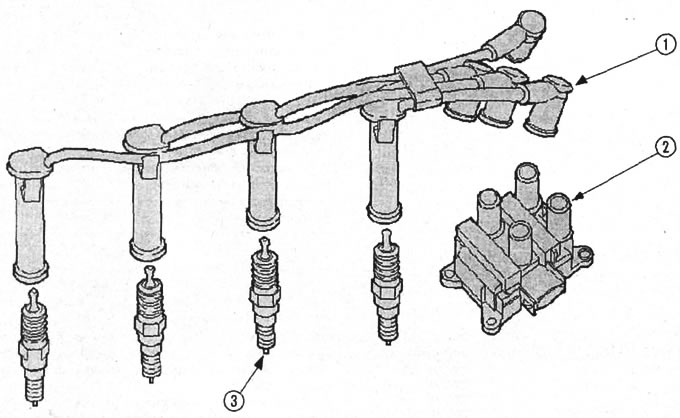

Elements of the ignition system: 1 - ignition wire; 2 - ignition coil; 3 - spark plugs

Touch control: The ignition system in the Focus is a high-performance electronic module that converts the 12V on-board voltage into an ignition voltage in excess of 30,000V. The ignition voltage is supplied to the spark plugs with angular degree accuracy. Work on electronic ignition systems must be carried out with extreme care - high voltage peaks can be life-threatening.

Traditional coil ignition systems, consisting of an ignition coil, ignition distributor, capacitor, ignition distributor pin, breaker contacts and high-voltage ignition wires, ensured, with their relatively limited flexibility, the operation of older gasoline engines: the ignition coil supplied a reversible voltage, a mechanical ignition distributor sparked the spark plugs. In the upper rev range, this occurred with a modest repositioning of the ignition timing, but usually before the piston, which was currently on the compression stroke, reached top dead center. In other words: the peripheral components of the engine, primarily the components for preparing the air-fuel mixture and the valve mechanism, were more or less dependent on the static performance of the ignition system. Coil ignition systems distributed sparks with the flexibility of a matchbox.

In the era of electronically controlled engines, this has changed: behind the scenes, completely invisible to the untrained eye, electronic components create connections that provide ignition and flexibility.

Amateur work and modern ignition systems

For do-it-yourselfers and ambitious amateur mechanics, that means ignition systems. rigidly integrated into the engine management, without special equipment give almost no application points «rational activity amateur». Under the hood of Focus also «run the show» «black boxes» - to penetrate into their inner life is possible only with the knowledge of an expert and highly sensitive test programs.

In all Focus gasoline engines, the ignition timing is calculated separately for each cylinder, based on the characteristics stored in the memory of the transmission control unit (RSM), as well as depending on the operating state of the engine at the moment.

Always in «double packing» - ignition spark

By design, the two ignition coils always supply sparks to the spark plugs in «double packing»: one spark ignites the fresh air-fuel mixture in the cylinder on the compression stroke, the other spark jumps in the opposite cylinder during the exhaust stroke. In other words: cylinders 1 and 4 and cylinders 3 and 4 always receive their spark at the same time.

TFR sensor supplies key parameters for each ignition spark

The signal of the crankshaft angle sensor serves as the calculation base (TFR). Its signal, previously digitized in PCM, controls the primary winding of the ignition coil. To do this, the PCM interrupts the voltage supply to the primary winding of the ignition coil for a short time. This creates high voltage (ignition voltage), which is discharged through the ignition wire at the spark plugs.

Transmission control unit (RSM) with different characteristics ensures the timely appearance of the ignition spark

The correct coordination of the ignition spark is provided by the PCM. In his memory, among other things, the theoretical basic parameters of various ignition points are stored. In order to adapt the dead theory to practice with maximum efficiency, the control unit evaluates the current information of the peripheral units of the engine. For example, it analyzes the signals of the TFR sensor and - in Zetec-SE engines - additional information from the knock sensor (KS). This current information must be constantly compared with the theoretical information on the hard disk at each crankshaft rotation. The black box before each individual change in the composition of the working mixture is associated with the injection system, lambda probe, speed sensor, as well as various temperature sensors and an air mass meter under the hood of the Focus.

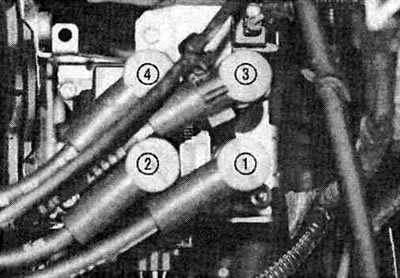

Touch Control: The ignition system in the Focus is a high performance electronic module that converts the 12V onboard voltage to an ignition voltage of over 30,000V. spark plug connector.

Optimum ignition timing depending on the load

The air-fuel mixture burns in the combustion chambers at different rates depending on the load condition (idle, part load, full load) and fresh air quality. In order to still maximize the energy of the fuel, the black box changes the ignition timing according to the load condition for each individual cylinder. The best option is when the fresh gas is ignited at the moment of maximum compression. In a four-stroke engine, this is the point at which the piston wants to go from raising the compression stroke to the reverse stroke of the power stroke.

Time shift - ignition and combustion

However, the ignition timing is not exactly at top dead center (TDC), since it takes about three thousandths of a second to ignite the mixture. In this regard, the ignition spark receives a green light while the piston is moving up. On the contrary, the maximum compression pressure occurs when the piston just steps over TDC. Since it always takes the same time to ignite the air-fuel mixture, the ignition timing shifts more and more from TDC to the advance side as the engine speed increases.

Visitor comments