knock sensor: works on the basis of piezoceramics, i.e. material that has long replaced flint in lighters. Piezoceramics convert mechanical energy, such as tension or pressure, into electrical voltage. The slightest disharmony is enough, for example, uncontrolled vibration of the engine block during «detonation combustion», to activate the sensor. He feels the vibrations and reports them to the on-board computer. As a result, the ignition timing of the corresponding cylinder is immediately corrected (about -5'). The remaining cylinders continue to operate as before until the sensor detects and reports failures in their environment. Immediately after this, the ignition timing is changed based on the nominal ignition timing and within one operating cycle until in the retarded direction, until the combustion process is normalized. The maximum offset range is -15°.

With proper combustion, after a short time, the ignition timing in the cylinder gradually returns to the advanced position.

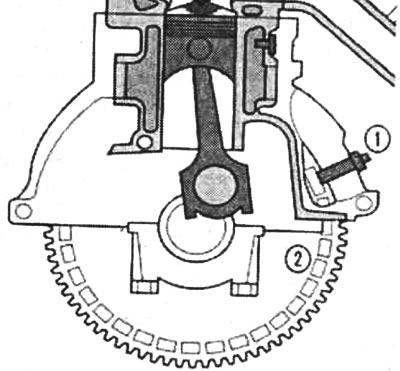

Speed sensor: an induction sensor that, by means of a control unit, turns on and off the current to both ignition coils. The sensor has an integrated magnet and coil. The control is taken over by special impulse jumpers on the engine flywheel: whenever the jumper passes the sensor, the electromagnetic field in the permanent magnets changes - then the coil generates voltage. In order to determine the position of the crankshaft as an acceptable TDC signal, the flywheel for the first and last cylinders, before each of their TDC, omissions of two impulse jumpers are made as a base mark. The control unit processes these voltage signals as a source of information about the engine speed.

Crankshaft position sensor: 1 - sensor; 2 - section fields.

Visitor comments