- 1.4L R4 16V (80 HP);

- 1.6L R4 16V (100 HP);

- 1.6L R4 16V Duratec Ti-VCT variable valve timing (115 HP);

- 1.8 L R4 Duratec-HE 16V (125 HP);

- 2.0L R4 16V (145 HP);

- as well as Duratorq 1.8L R4 16V turbodiesel (115 HP).

Only the R4 16V Duratec Ti-VCT engine is described in this book as being installed in most of the production of cars, having much in common with the rest of the engines in the family and the most complex of them.

The R4 16V Duratec Ti-VCT engine has four overhead camshafts, five-way camshafts, and four valves per cylinder. The camshafts are driven by a reinforced toothed belt. Belt tension is provided by a tension roller spring. The valves are driven directly from the camshafts through cylindrical tappets, which simultaneously serve as adjusting elements for clearances in the drive.

cylinder head made of aluminum alloy according to the transverse cylinder purge pattern (inlet and outlet ports are located on opposite sides of the head). Seats and valve guides are pressed into the head. The intake and exhaust valves have one spring each, fixed through the plate with two crackers. The head of the block is centered on the block with two bushings and attached with ten screws. A non-shrink metal-reinforced gasket is installed between the block and the head. In the upper part of the cylinder head, there are five bearing supports for two camshafts. The function of the front supports is performed by the caliper of the dynamic variable valve timing system (see below in this subsection), which simultaneously keeps the camshafts from axial displacement. The rest of the supports are detachable. The lower parts of the supports are made in one piece with the cylinder head, and the upper (lids) – attached to the head with screws. The holes of the supports are processed complete with covers, so the covers are not interchangeable and each of them has a serial number.

Cylinder block is a single casting of special high-strength cast iron, forming cylinders, a cooling jacket, the upper part of the crankcase and five crankshaft bearings made in the form of crankcase baffles. The cylinders are bored directly into the body of the block. In the lower part of the block, five beds of main bearings are made with removable covers bolted to the block. The main bearing caps are machined complete with the block and are not interchangeable. In beds of bearings (at the top of the supports) there are outlet holes of oil channels designed for lubrication of main bearings, and through holes into which ball valves with nozzles are pressed, through which oil is sprayed onto the piston bottoms and cylinder walls. On the cylinder block, special lugs, flanges and holes for fastening parts, assemblies and assemblies, as well as channels of the main oil line are made.

Crankshaft, made of high-strength cast iron, rotates in main bearings equipped with thin-walled steel liners with an anti-friction layer. The upper liners installed in the cylinder block have a groove on the inner surface and a through slot through which oil flows from the outlet of the oil channel to the ball valve with a nozzle. The bottom liners have neither grooves nor slots. The axial movement of the crankshaft is limited by two identical thrust half rings. A flywheel is attached to the rear end of the crankshaft with six bolts. At the front end of the crankshaft, a timing gear drive pulley and an auxiliary drive pulley are installed.

Pistons with a short skirt are made of aluminum alloy. On the cylindrical surface of the piston head there are annular grooves for two compression and oil scraper rings. Six drillings in the oil scraper ring groove are designed to drain the oil removed by the ring from the cylinder walls. Two of these holes bring oil to the piston pin.

piston pins tubular sections are installed in the piston bosses with a gap and are pressed with an interference fit into the upper heads of the connecting rods, which are connected by their lower heads to the connecting rod journals of the crankshaft through thin-walled liners, the design of which is similar to the main liners.

connecting rods steel, forged, with an I-section rod. Connecting rods are processed complete with covers. In order not to confuse them during assembly, the serial number of the cylinder is applied to the side surfaces of the connecting rods and covers.

Camshafts cast, cast iron.

The gas distribution mechanism is covered with plastic cylinder head cover. It has an oil separator for the crankcase ventilation system.

Lubrication system combined (see more details. «Lubrication system»).

From below, an oil sump cast from an aluminum alloy is attached to the cylinder block. The oil sump flange is sealed with FORD WSE-M4G323-A4 gasket. The crankcase has an oil drain hole closed with a screw plug.

Oil filter full-flow, non-separable, with bypass and anti-drainage valves.

Crankcase ventilation system closed, forced, with removal of crankcase gases through the oil separator into the cavity of the air filter.

Cooling system sealed engine, with expansion tank (see more details. «Cooling system»).

The engine power system consists of an electric fuel pump installed in the fuel tank, a throttle assembly, a fine fuel filter and a fuel pressure regulator installed in the fuel pump module, a fuel pressure pulsation compensator, injectors and fuel lines, and also includes an air filter.

Ignition system microprocessor, consists of an ignition coil, high-voltage wires and spark plugs. The ignition coil is controlled by the electronic engine control unit. The ignition system during operation does not require maintenance and adjustment.

power unit (engine with gearbox, clutch and final drive) mounted on three supports with elastic rubber elements: two front ones, which take the bulk of the power unit, and a rear one, which compensates for the torque from the transmission and the load that occurs when the car starts, accelerates and brakes.

A distinctive feature of the R4 16V Duratec Ti-VCT engine is the presence of an electronically controlled variable valve timing system (VCT), dynamically adjusting the position of the camshafts. This system allows you to set the optimal valve timing for each moment of engine operation, which, in turn, achieves increased power, better fuel efficiency and lower exhaust emissions.

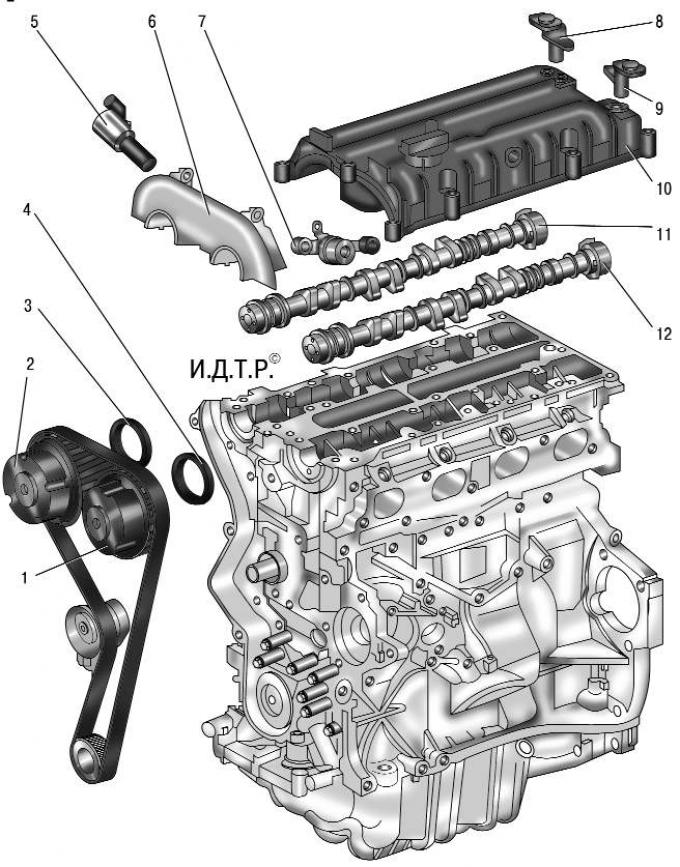

Pic. 5.1. Elements of the variable valve timing system (VCT): 1 - intake camshaft VCT mechanism; 2 – the VCT mechanism of a final camshaft; 3 – an epiploon of an inlet camshaft; 4 – an epiploon of a final camshaft; 5 - solenoid valve for adjusting the position of the exhaust camshaft; 6 - support system VCT; 7 - solenoid valve for regulating the position of the intake camshaft; 8 - exhaust camshaft position sensor; 9 - intake camshaft position sensor; 10 – a cover of a head of the block of cylinders; 11 - the master ring of the exhaust camshaft position sensor; 12 - the setting ring of the intake camshaft position sensor

The timing belt drives gears 1 and 2 (pic. 5.1) VCT of the intake and exhaust camshafts respectively. VCT mechanisms, in turn, drive the corresponding camshafts.

To determine the instantaneous position of the camshafts, sensors 8 and 9 of the camshaft position are installed at the rear end of each of them. On the necks of the camshafts are the driving rings 11 and 12 of the position sensors.

A caliper 6 of the VCT system is installed on the front of the cylinder head, which simultaneously acts as a cover for the front bearings of the camshafts and a holder for oil seals 3 and 4 of the camshafts. Two solenoid valves 5 and 7 are fixed on the caliper, which hydraulically control the VCT mechanisms. The solenoid valves, in turn, are controlled by the electronic engine control unit.

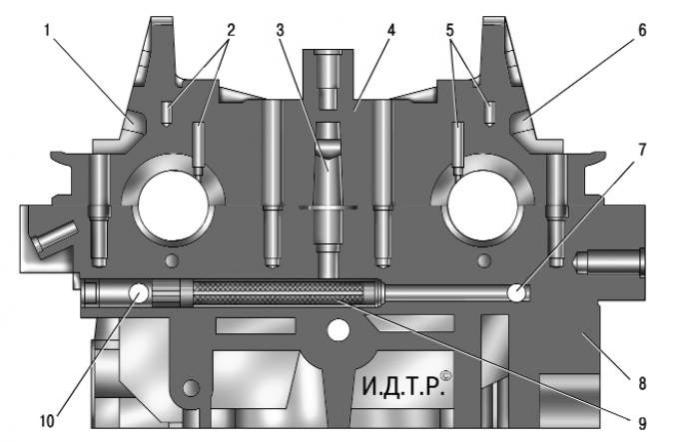

Pic. 5.2. Scheme of the hydraulic system VCT: 1 - socket for installing the solenoid valve for adjusting the position of the exhaust camshaft; 2 - channels connecting the solenoid valve and the exhaust camshaft VCT mechanism; 3 - channel for supplying oil to electromagnetic valves from the main oil line of the engine; 4 – support VCT; 5 - channels connecting the solenoid valve and the intake camshaft VCT mechanism; 6 - socket for installing the solenoid valve for adjusting the position of the intake camshaft; 7 - channel for supplying oil from the main oil line of the engine to the intake camshaft; 8 – a head of the block of cylinders; 9 - oil filter of the VCT system; 10 - channel for supplying oil from the main oil line of the engine to the exhaust camshaft

The oil supplied to the VCT hydraulic system from the main engine oil line, in addition to the main oil filter of the lubrication system, is cleaned in an additional filter 9 (pic. 5.2) hydraulic systems VCT. Additional oil cleaning is required because the solenoid valve bores are very small and contaminant particles as small as 0.2 mm can already lead to failure of the VCT system. At the same time, the filter acts as a safety valve to ensure an uninterrupted supply of oil to the VCT hydraulic system under all circumstances. The filter is non-removable and cannot be replaced.

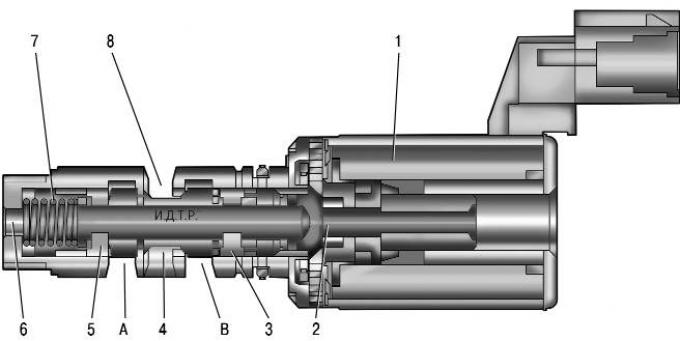

Pic. 5.3. Solenoid valve VCT: A - a cavity connected by a channel in the caliper with the first working chamber of the VCT mechanism; B - cavity connected by a channel in the caliper with the second working chamber of the VCT mechanism; 1 - electromagnet; 2 - valve spool; 3 – annular groove connected by a channel in the caliper to the second working chamber of the VCT mechanism; 4 - an annular groove for draining oil; 5 - an annular groove connected by a channel in the caliper with the first working chamber of the VCT mechanism; 6 - hole for supplying oil from the main line; 7 - valve spring; 8 - oil drain hole

Solenoid valve VCT consisting of solenoid 1 (pic. 5.3) and the valve, which includes the spool 2 and the spring 7, according to the signals of the electronic engine control unit, supplies oil under pressure from the main line of the lubrication system to the working cavities of the VCT mechanisms or drains the oil from these cavities, which leads to the mutual movement of the elements of the mechanisms and, as a result, to a dynamic change in the position of the camshafts.

While the engine is idling, the electronic engine control unit repeatedly activates the electromagnetic valves for short periods of time in order to clean their elements and channels from contaminants that accidentally get into them.

When the power supply to the VCT solenoid valves is turned off, the oil supply holes 6 from the main line and drain 8 are completely open and the VCT mechanisms are set to their original position. In this case, the engine runs without changing the valve timing.

Elements of the VCT system (solenoid valves and mechanisms for dynamically changing the position of camshafts) are precision-manufactured units. In this regard, when performing maintenance or repair of the variable valve timing system, only the replacement of the complete system elements is allowed.

NOTE: This section describes engine repair work available to a novice master: replacing seals, power unit suspension mounts, checking compression, adjusting and lapping valves, etc. For the overhaul of the engine with its complete disassembly, special equipment and tools are required, as well as the appropriate technical training of the performer. Therefore, if such repairs are necessary, contact an authorized service station.

Visitor comments