Withdrawal

Attention: if it is necessary to replace only the cuffs, then the removal of the cardan shaft assembly is not required, see resp. chapter.

Loosen the axle nut with the vehicle on wheels, see point 11.6.

Mark the position of the wheels on the hub with paint in order to install them in their original place during assembly. Loosen the wheel nuts with the vehicle lowered. Raise the front of the car and remove the front wheels.

Remove the brake caliper see point 15.2.

Hang the brake caliper with a wire from the inner mudguard, taking care not to twist or strain the brake hose. The brake hose remains connected, otherwise you will have to bleed the air from the brake system after installation.

Where necessary, disconnect the multi-pin connector of the brake pad wear indicator.

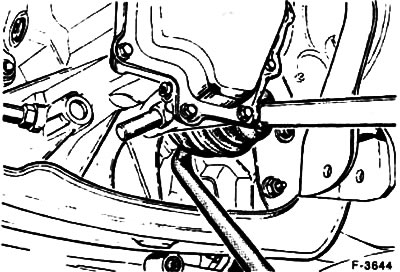

Disconnect the anti-roll bar connecting rod.

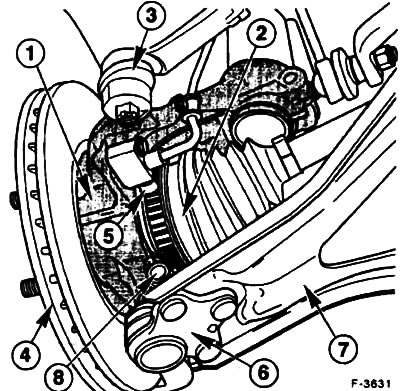

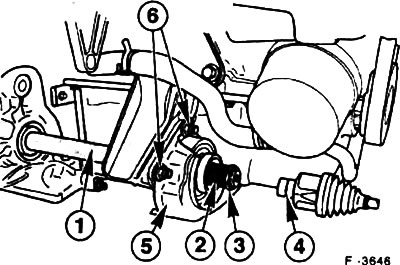

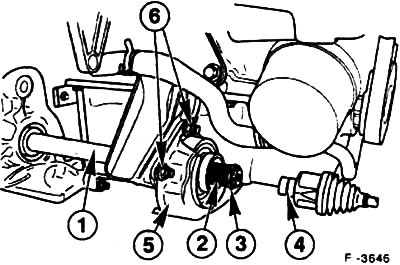

Press the pin -3- of the tie rod out of the steering knuckle -1-, see point 13.3.

Where necessary, unscrew the ABS sensor -5- from the steering knuckle.

Remove the brake disc -4-, see point 15.4.

Turn out a tightening bolt -8- and a nut of a spherical support -6- of the lower cross-section lever -7- and pull down the cross-section lever from a rotary fist.

Attention: do not damage the collar of the ball stud. Wrap it in a rag to protect it.

Turn out a clamping bolt of fastening of a shock-absorber rack on a rotary fist.

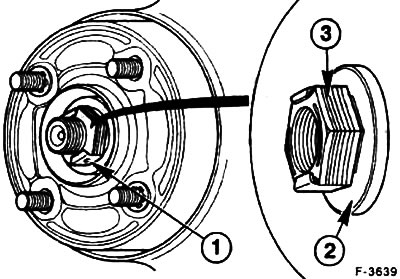

Loosen axle nut -1-. The self-locking axle nut -3- with free-turning washer -2- can be reused up to five times.

Compress the steering knuckle from the semi-axial cardan with a puller.

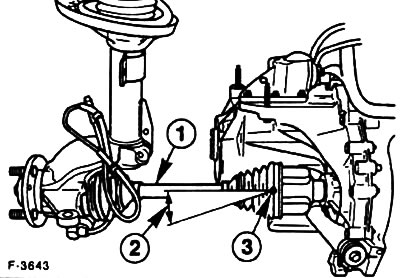

Pull the steering knuckle out and remove the cardan from the steering knuckle. In order to avoid undesirable loading of the inner joint, suspend the cardan shaft -1- on a wire. The maximum allowable inclination angle of the internal hinges is 18°. The outer hinge has a stop, but it must not be pressed when it stops.

Left cardan shaft

If it is necessary to remove the driveshaft assembly, install a large pry bar between the pivot and the gearbox housing. Rotate the mount and remove the hinge.

Attention! Use wooden spacers to prevent damage to the box. Do not pull on the cardan shaft!

Right cardan shaft

Turn out bolts -6- of an average support.

Remove the heat shield -5-. Damaged one-piece casing (issue until 6/93) replace with a new one consisting of two parts.

Pull off the cardan shaft.

Installation

Before installation, check the condition of the propeller shaft sealing ring.

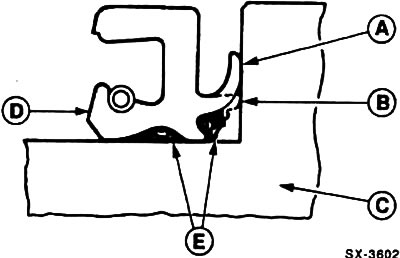

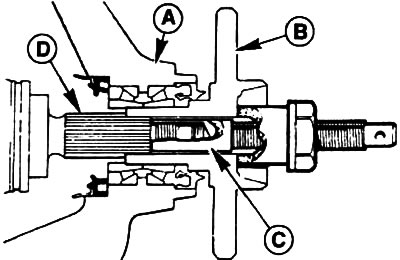

A - new O-ring tab, B - worn tab, C - wheel hub or driveshaft, D - O-ring, E - grease.

Remove the worn O-ring with a flat chisel.

Attention! do not damage the gearbox housing.

Attention! if the O-ring is defective or worn, check the condition of the rollers and bearing raceways.

Lubricate the new O-ring as shown in the illustration and press evenly with a pipe of the correct diameter.

Right cardan shaft

Replace retaining ring -3-.

Clean the splines -2- of the intermediate shaft -1- and thoroughly lubricate them over the entire surface with special grease FORD-SQM-1C9004-A (6-8 gr.).

Push on the cardan shaft.

Left cardan shaft

Clean the splines and threads of the propeller shaft and lubricate with a thin layer of grease.

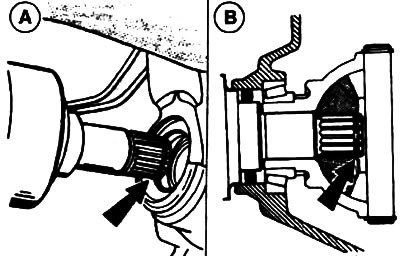

Insert the propeller shaft with a new circlip -arrow A- into the splines of the spherical drive gear and lock it firmly -arrow B-. With light reciprocating movements, check the reliability of the locking of the cardan shaft.

Rotate the steering knuckle outward and guide the driveshaft by hand into the wheel bearings. Install the washer, screw on the used wheel axle nut and, by screwing on the axle nut, pull out the cardan shaft knuckle. Do not tighten the wheel axle nut. Finally, unscrew the axle nut and replace.

Attention! if the axle nut cannot be screwed on, then tighten the hub to the stop with the FORD 14-041 special tool. Rotate the wheel hub during this process to properly seat the bearings. Remove the fixture and screw the hub axle nut until it stops by hand, do not tighten the nut.

Insert the ball joint of the transverse arm from below into the hole of the steering knuckle and tighten the clamping bolt with a torque of 80 Nm (on a new ball joint - with a torque of 55 Nm).

Screw in, if removed, the ABS sensor, 10 Nm.

Install the brake disc and secure it with two new stoppers.

Install the brake caliper see point 15.2.

If the brake hose is loosened, bleed the air from the brake system, see clause 15.12.

Connect, where required, the multi-pin connector of the brake pad wear indicator.

Attach the tie rod head to the steering knuckle and tighten with a torque of 25-30 Nm. secure the connection with a new cotter pin. If the cotter pin does not fit into the hole, tighten the threaded connection until the cotter pin enters the hole.

Tighten the anti-roll bar connecting rods with a torque of 50 Nm.

Install the front wheels so that the marks made earlier coincide. Apply a light coat of grease to the centering surface on the wheel hub before installing the wheels. Screw on the wheel nuts. Lower the vehicle and tighten the nuts crosswise to 100 Nm.

Tighten the front axle nut to 340 Nm. To lock the wheels, apply the parking brake and have an assistant depress the foot brake pedal.

Attention! while the car must be on wheels.

Check the freedom of movement of the brake hose and ABS sensor wire. To do this, the assistant must turn the front wheels from one extreme position to another.

Check the oil level in the gearbox, top up if necessary, see point 10.6.

Visitor comments