Attention! maintain exceptional cleanliness. Even minor contamination leads to the destruction of the hinge.

Grease specification: FORD-SQM-1C9004-A.

Amount of grease for the inner joint: 180 gr.

Amount of grease for the inner joint: 100 gr.

Damaged bearing balls lead to cyclic shock loads, which can be determined by the noise of the joint. In this case, the hinge must be replaced.

Attention! on a car with high mileage, it is recommended to replace both rubber cuffs. Also replace both bellows when removing the hinges.

Withdrawal

Mark the position of the cuff with a marker.

Remove shock absorber assembly with steering knuckle and cardan shaft, see point 11.1.

Attention! make sure that the spherical rollers do not fall out.

Remove the spherical rollers.

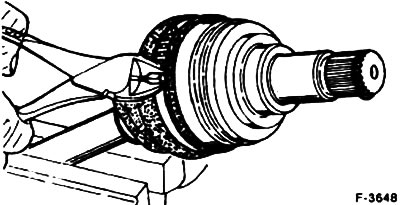

Fix the cardan shaft in a vise with protective jaws.

Remove the internal tripoid joint by first removing the retaining ring with suitable pliers. Mark the position of the cardan shaft with a felt-tip pen. Under some circumstances, a puller is required for removal.

Cut the cuff fastening clamp with wire cutters and remove the clamp.

Remove the rubber cuff.

Installation

Lightly lubricate the surface of the cardan shaft so that the cuff is inserted more easily.

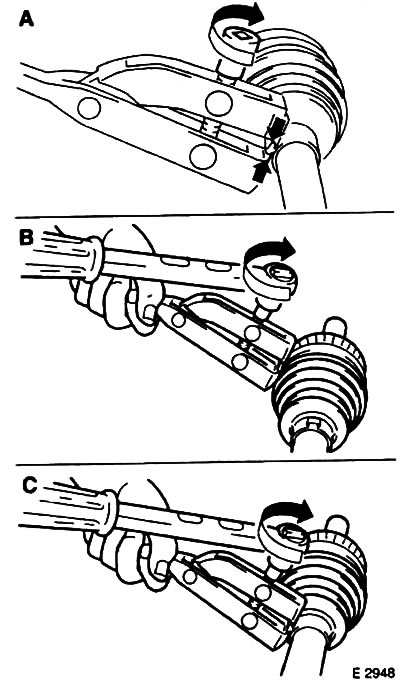

Press the outer collar into the annular groove of the hinge. At the same time, insert a small screwdriver under the cuff along the large diameter to release air from under the cuff. Adjust the position of the cuff in accordance with the previously applied marking. Pay attention to the sufficiency of lubrication of the hinge.

Attention! do not crimp the corrugated cover after installation.

Lay the tension tape in the annular groove of the cuff and tighten it with a special FORD-14-044 tensioner, while tightening the tension bolt with a torque wrench with a torque of 20 Nm.

Put the inner collar on the shaft, correct its location in accordance with the applied marking and fasten it on the small diameter with a tape with a torque of 20 Nm.

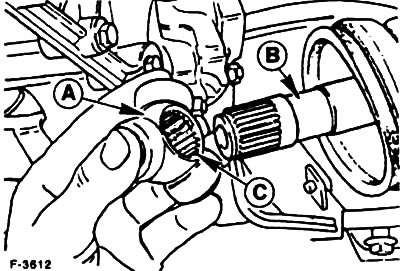

Inner joint: Slide the tripod -A- onto the propeller shaft -B- and secure with a new circlip. At the same time, follow the previously applied markings. Insert the Tripoid until it stops, if necessary, use a pipe of a suitable diameter.

Attention! do not damage the installation sites of the spherical rollers of constant angular velocity.

Install, lubricated with special grease SQM-1C9004-A, rollers of equal angular speeds.

Install the shock absorber assembly with the steering knuckle and cardan shaft, see point 11.1.

Slide the cuff over the inner hinge. At the same time, insert a small screwdriver under the cuff to release air from under the cuff. Insert the tripoid joint all the way inward and pull it back 20 mm. In this position, remove the screwdriver. Adjust the position of the cuff in accordance with the previously marked markings. Pay attention to the sufficiency of lubrication of the hinge.

Install the front wheels so that the marks made earlier coincide. Apply a light coat of grease to the centering surface on the wheel hub before installing the wheels. Screw on the wheel nuts. Lower the vehicle and tighten the nuts crosswise to 100 Nm.

Tighten the upper strut nut to 45 Nm.

Check the freedom of movement of the brake hose and ABS sensor wire. To do this, the assistant must turn the front wheels from one extreme position to another.

Visitor comments