Attention! For diesel engines, a compression pressure tester with a large measuring range is used. The pressure difference between the individual cylinders must be max. 3.0 bar (in diesel engine 5.0 bar). If the pressure in one or more cylinders differs from the other cylinders by more than 3.0 bar (in a diesel engine more than 5.0 bar), then it says. that the valves are defective, the piston rings or the working surfaces of the cylinders are worn out. If the wear limit is reached, the engine must be overhauled or replaced. The results of pressure measurements depending on the use of various measuring instruments and the number of revolutions of the starter may be different. 11-13 bar should be taken as guideline values for petrol engines, 20-25 bar for compression pressure for diesel engines. Much more important is the pressure difference between the individual cylinders.

Check the engine oil level, add oil if necessary, otherwise the hydraulic valve lifters will not function properly. If you have added oil, then start the engine for a short time.

To check the compression, the engine temperature must be at least +30°C, the engine must be warm to the touch.

Gasoline engines

Switch off the ignition.

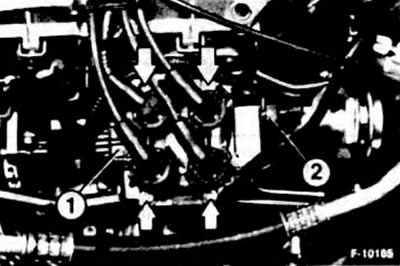

Remove the supply wires -1- and -2- from the ignition coil.

Disconnect by hand or using special pliers, such as HAZET 1849, all tips from the spark plugs.

Then clean with compressed air (if he is) sockets in the cylinder head, unscrew the old spark plugs using a spark plug wrench.

Turn the engine a couple of times with the starter to remove wear and scale.

Attention! Shift the transmission to the idle position and apply the parking brake. Press or screw the compression pressure tester into the spark plug hole according to the operating instructions.

Have your assistant fully depress the gas pedal and keep it in the down position throughout the entire test process.

Rotate the engine several times until the gauge no longer registers an increase in pressure.

Check all cylinders one by one and record the measurements.

Finally, screw in the spark plugs, connect the ignition wires, see also n. 28.

Diesel engine

Check the valve clearances, they must be correct, otherwise adjust them, see paragraph 1.17.

Switch the ignition key to position "0".

Unscrew the electrical wire from the high pressure fuel pump shutoff valve. Valve position see section 7.7.

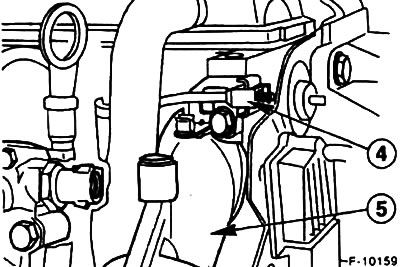

Unscrew the glow plug supply cable on the bracket -4-, insulate it and put it aside. To insulate the tip of the wire, wrap it with electrical tape. 5 - vacuum pump.

Remove the wires from the glow plugs, unscrew the candles.

Screw in the compression pressure tester instead of the glow plug and turn on the starter until the arrow on the tester stops changing its position. Check all cylinders one by one.

Set the ignition switch key to position "ABOUT".

Install the candles see point 7.5.

Connect the wires to the shut-off valve and to the glow plugs.

Visitor comments