Remove the left transverse suspension arm as follows:

- disconnect the storage battery;

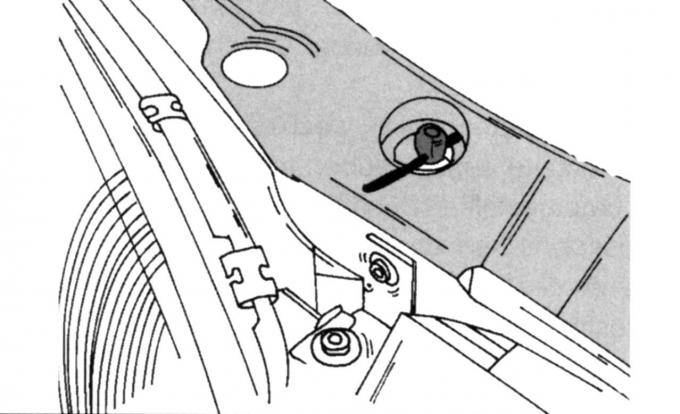

Pic. 161. Radiator mount

- insert pins on both sides of the radiator (see fig. 161), to prevent it from falling;

- loosen the wheel nuts and jack up the front of the car;

- remove the front wheels in order to make it easier to get close to the transverse suspension arm;

- remove the reflector under the radiator (fixed with bolts and clamps);

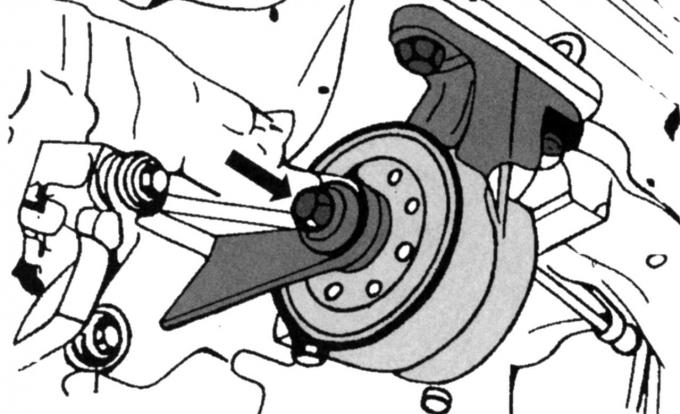

Pic. 194. Location of the rear bearing on a car with a manual gearbox

- on cars with a mechanical transmission turn away an average bolt of the back bearing which location is shown in fig. 194, on vehicles with automatic transmission, unscrew the two bolts located below;

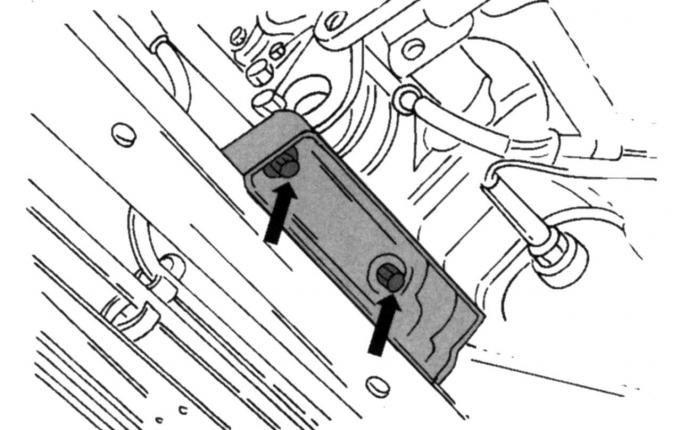

Pic. 195. Removing the support element of the front suspension

- remove all front suspension bolts (pic. 195);

- if there is an air conditioner, remove the condensate tank (two bolts);

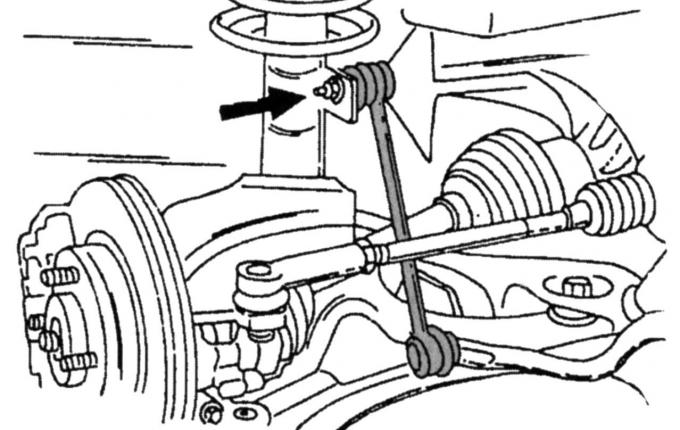

Pic. 196. Location of the connection of the anti-roll bar linkage with the shock absorber strut

- Turn away draft of the stabilizer in specified on fig. 196 place in front of the shock absorber;

- holding the clamping bolt of the ball joint from the rear side, unscrew the nut and knock out the bolt;

- insert a screwdriver into the slot and press down on the transverse lever so that the ball joint pin disengages from the steering knuckle, while trying not to damage the rubber cuff of the ball joint;

- similarly disconnect the stabilizer and the transverse lever on the other side;

- Unscrew the protective shield under the crankshaft;

- mark the exact position of the subframe and unscrew the four bolts (two at the top and two at the bottom) on the outer sides, while the frame must rest on the jack, since after unscrewing the bolts it may fall;

- lower the frame to gain access to the transverse arm mounting bolts;

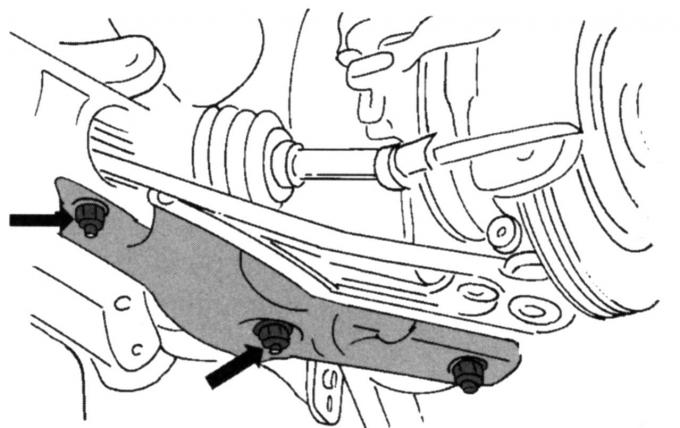

Pic. 197. The location of the bolts of the left transverse suspension arm (except for the 200 hp model)

- on all vehicles, with the exception of vehicles with a 200 hp engine, it is now possible to unscrew the bolts securing the left and, if necessary, the right transverse arm (both bolts and nuts are in the positions shown in fig. 197; on vehicles with a 200 hp engine. the transverse arm is attached with four bolts and nuts, which can also be unscrewed from below);

- Remove the transverse lever.

Rubber plugs of the cross-section lever replace if they were knocked out. Since the bushings can only be set in the correct position with a special tool, take the transverse arm to a specialist workshop.

Install the removed parts in reverse order. Align the subframe in a free state.

Install the left transverse suspension arm as follows:

- install both transverse levers on the subframe and insert the bolts from above; holding the bolt heads, tighten both nuts to 50 Nm, then mark the position of the nuts and tighten another quarter turn (bushings must be pretensioned according to the regulations);

- on a car with a 200 hp engine. the nuts are tightened in the following order: both large nuts are tightened to 115 Nm, both small nuts to 70 Nm (no corner tightening required);

- install the subframe with a jack in the correct position, align according to the marks and tighten the four bolts with a torque of 135 Nm;

- Install the ball joint of the rear transverse arm in the steering knuckle (if necessary, slightly open the clamping slot), insert the bolts and tighten the connection to 85 Nm;

- set the back stop against turning (power unit stop), while tightening the long and middle bolts with a torque of 120 Nm (vehicles with manual transmission), bolts inserted from below - torque 48 Nm;

- put the car on the wheels and tighten the wheel nuts.

Further assembly is carried out in the reverse order of removal.

Visitor comments