Operating principle of the control device EEC IV

An electric fuel pump delivers fuel from the fuel tank through the fuel filter to the jets, which are located on the distribution pipe. The pressure regulator located on the distribution pipe maintains a constant pressure in the fuel system depending on the vacuum in the intake pipe (pressure should be 2.5 bar). Excess fuel flows back to the fuel tank through the return hose. Rapid fuel circulation keeps the jets cool. The engine draws in fresh air through the air filter and intake pipe. An instrument is installed in the intake pipe which measures the mass of the air drawn in, using the following principle: an electrically heated coil is cooled by the passing air drawn in. In order to keep the temperature of the coil constant, the heating current changes accordingly depending on the density/temperature of the sucked air. Based on the fluctuations in the heating current, the control device determines the mass of the sucked-in air. The current throttle position is taken as the reference value. The control device regulates the amount of fuel injected and the duration of injection according to the mass of air and the engine speed. If the jet is open longer, more fuel is injected. Each jet is controlled separately according to the ignition order. There is such a special concept: sequential injection. Additional sensors and actuators measure the correct amount of fuel in special driving situations.

The fuel injection control unit controls the idle speed via the idle speed control valve. This valve regulates the amount of air at idle without the throttle being actuated. As a result, the idling speed remains constant, regardless of whether additional consumers are working or not at that moment, such as power steering or a cooling compressor.

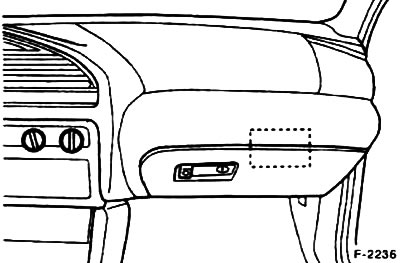

The electrical control unit is located on the right under the dashboard. The connector plug can be reached from the engine compartment after removing the power steering pump reservoir. Before disconnecting the connection plug, the hexagon head screw in the plug must be unscrewed.

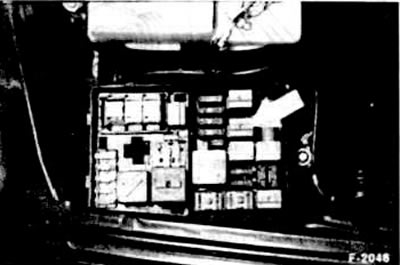

The fuel pump relay supplies current to the fuel pump. The protective circuit stops the current supply as soon as a pulse characterizing the number of revolutions is not received, for example, if the engine has stalled. The relay is located in the fuse box in the engine compartment.

The oxygen sensor measures the oxygen content in the exhaust gases and sends appropriate signals to the control unit. After that, the control device regulates the amount of fuel injected so that the exhaust gases burn optimally in the catalyst.

The intake air temperature sensor measures the intake air temperature, another temperature sensor on the coolant temperature regulator housing measures the coolant temperature.

The fuel tank vent solenoid valve is controlled according to the operating state of the engine. The fuel vapors generated in the fuel tank are collected by the activated carbon filter and fed through the combustion valve. Fuel vapors are used by means of an activated carbon filter and are not emitted into the surrounding atmosphere.

There are inductive sensors on the flywheel and camshaft sprocket for the intake cams. They provide information about the current engine speed and crankshaft position to the control unit of the fuel injection system.

The ignition system has no moving parts, so it does not wear out, except for the spark plugs. If the compensation plug in the engine compartment is disconnected, the tank can be filled with fuel of inferior quality, see chapter "Ignition system". If you refill petrol Super (minimum 96 ROZ), the compensating plug must be reconnected.

The control device controls the exhaust gas recirculation system and the pulsed air system. Both systems reduce the content of harmful substances in the exhaust gases: the pulsed air system works when the engine is hot. Fresh air is dosed into the exhaust gases, which allows the exhaust gases to burn better in the catalyst. Exhaust gas recirculation reduces the emission of nitrogen oxides. This is achieved by the fact that a small part of the exhaust gases is again added to the intake air. The sensors and valves required for this are located on the bracket -1- on the front wall of the engine in the engine compartment. 3 - electronic differential pressure transducer; 4 - impulse magnetic valve; 5 - electronic vacuum regulator (2 - ignition control device, only in automatic transmissions, otherwise integrated into the engine control device).

Other functions of the engine controller: The cooling fan is controlled according to the engine temperature and (if there) from the air conditioner. The shift points of the automatic transmission are adjusted according to road conditions.

Visitor comments