|

PROCEDURE |

- A defective injector sometimes exposes itself already at idle by applying to it «bare hand»: it doesn't vibrate - unlike the others. Not to «fry» your fingers, test with a cold engine.

- To check the voltage, pull out the valve plugs in series with the engine running and connect to the LED probe (not a control lamp).

- If the LEDs flash rhythmically, the connection is OK. Before you put all the blame on the nozzle, still do not trust the control unit - you should still contact the workshop for the necessary check.

- If you want to better measure the resistance instead of checking the voltage, pull out the plug and connect both injector pins to the multimeter. At 20 C, the resistance value should be 14.5 1 Ohm.

- If strong discrepancies are detected, then replace the corresponding nozzle.

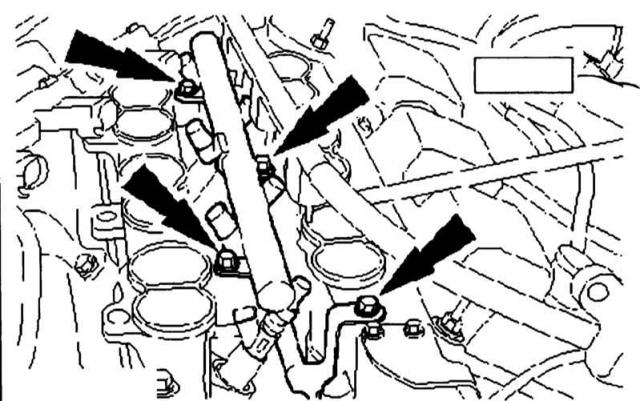

- To do this, dismantle the pipeline of the fuel distributor (screws are indicated by arrows) along with injectors.

Duratec-VE engine fuel distributor pipeline. |

- Pull the plugs from the injectors - the fuel lines remain connected.

- To operate the fuel pump and the fuel system can generate pressure, repeatedly turn the ignition on and off.

Presence of a drop - checking each nozzle - Inspect each nozzle in sequence: only one drop should come out - if more flows, replace the nozzle.

- To check the injection jet, it is necessary to dismantle the pipeline of the fuel distributor. Fuel lines to all injectors remain connected. Pull out - before the injector being checked - the plugs from the other injectors and drain the fuel into a container.

- When the ignition is turned on, the injector should inject fuel in a cone-shaped jet.

- Check all injectors in this way.

|

|

Only in Duratec engines direct «wire» to the throttle valve - thrust of the gas pedal

In gasoline engines, a mechanical Bowden cable connects the accelerator pedal to the throttle valve. Bowden cables, meanwhile, had not previously been random details here. However, when they are improperly stowed in the engine bay, they can very well get on someone's nerves. For example, when it «soul» clamped in a protective casing and as a result, trouble can happen to the throttle valve: in extreme cases, the engine starts «howl» with each switch-on process, since «inhibited» thrust places much higher demands on the throttle return mechanism. To make these symptoms unfamiliar to you, sometimes follow the winding paths of gas thrust and treat all its turning mechanisms with a couple of drops of lubricating oil - and even more so after washing the engine.

State of the art for DuraTorg motors – «wired control»

If your Mondeo is equipped with a diesel engine, then you can safely forget our advice: in diesel units, communication between the accelerator pedal and the fuel pump is carried out by an electrical wire. Experts are talking here about the so-called regulation of the type «wired control». The lifting path of the pedal acts on the throttle sensor, the electrical impulses from which then fall through the electrical wire to the fuel pump control unit.

Visitor comments