Note: Before removing, mark the position of the subframe for correct subsequent installation.

Warning: When removing and installing, the gearbox must be securely supported by a jack.

This work is best done with an assistant.

When removing the gearbox, the entire subframe and wheel drive shafts are removed.

In addition, you will need a device to lift the engine.

To remove the gearbox on a 16-valve engine:

- disconnect a wire from the negative plug of the storage battery, and also disconnect all wires attached to it. The cable ties must be cut and replaced accordingly with new ones when installed;

- Remove the storage battery;

- Loosen the nuts in the center of both chassis shock absorbers by five turns (at both sides);

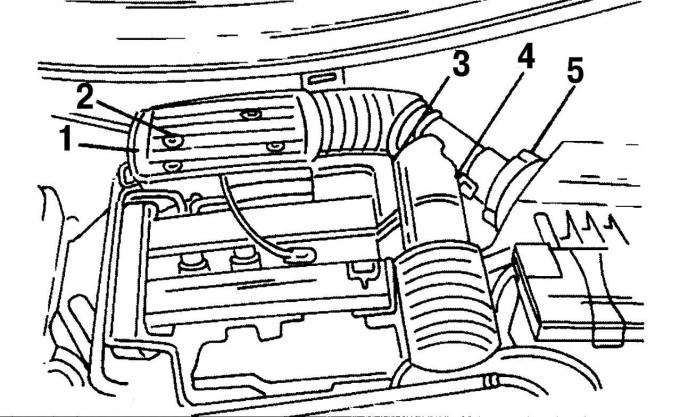

Pic. 22. Fixing the air intake pipes: 1 - mounting bolts, 2 - plug, 3 - plug, 4 - clamp, 5 - low pressure hose

- remove four screws 1 (see fig. 22) fastening of an air branch pipe;

- remove plug 2 from the air meter and remove hose clamps 3 on the same side;

- Remove the multi-pin plug 4 of the intake air sensor;

- Remove hose 5 low pressure;

- remove the suction air pipe;

- Disconnect the ventilation hose between the air filter and the cylinder head cover;

- remove the rubber ring;

- lift and take out the air filter from fastening;

- from a motor compartment disconnect electric wires from a transmission. This includes the multi-pin plug for the reversing light switch and the ribbon cable «masses» between gearbox housing and body (both next to the air filter support);

- Disconnect the wiring from the clutch slave cylinder. To do this, remove the spring clip and pull the wire straight out of the connection. Clamp the wiring from the gearbox and tie it with a wire in a suitable place;

- Turn out screws between the engine and a transmission in the top part;

- unscrew the top screw fastening the starter and remove the connected cable «masses»;

- Disconnect all tips of wires and hoses of low pressure;

- Disconnect the fuel lines;

- loosen the wheel nuts and the wheel hub nut on the right side and place the front of the car on supports;

- raise the power unit;

- Remove both forward wheels;

- unscrew the shield in the wheel arch on the side of the engine belt pulley;

- unscrew the mudguard on the bottom of the car;

- put the car on supports;

- Disconnect from a subframe a shock-absorber bracket and pipelines of a hydraulic drive of a steering;

- Disconnect the system of rods and levers of the anti-roll bar from the shock absorber strut of the chassis;

- Disconnect the steering trapezium linkage from the rudder bipod;

- Disconnect the ball joint to the left and to the right of the lower surface of the steering knuckle;

- remove the multi-pin plug from the lambda probe and disconnect the cable tie;

- Disconnect the low pressure hose from the Air-Pulse system filter;

- Turn away an arm of the pipeline of a drive of a steering;

- completely remove system of release of the fulfilled gases;

- turn away from a transmission and take out together with an arm a cable of a drive of a transmission;

- unscrew the steering and the right stop from turning the engine from the subframe;

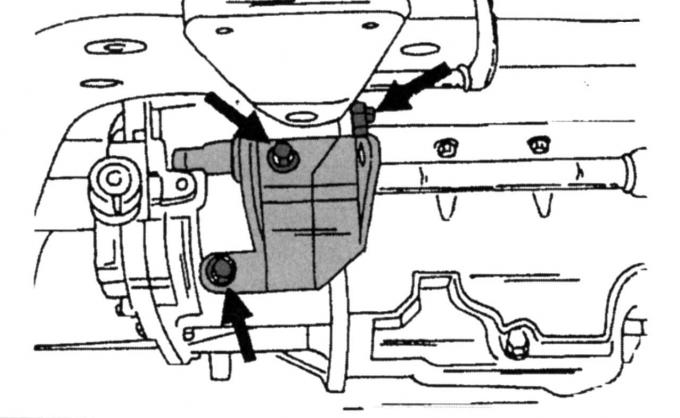

Pic. 156. The location of the attachment points of the stop console

- unscrew the three fasteners (pic. 156) and release the rear stop console from the drive;

- Turn out the average screw from the left emphasis from cranking of the engine and take an emphasis;

- unscrew the filter of the Air-Pulse system from the mounting on the stop;

- Turn away an arm of a radiator;

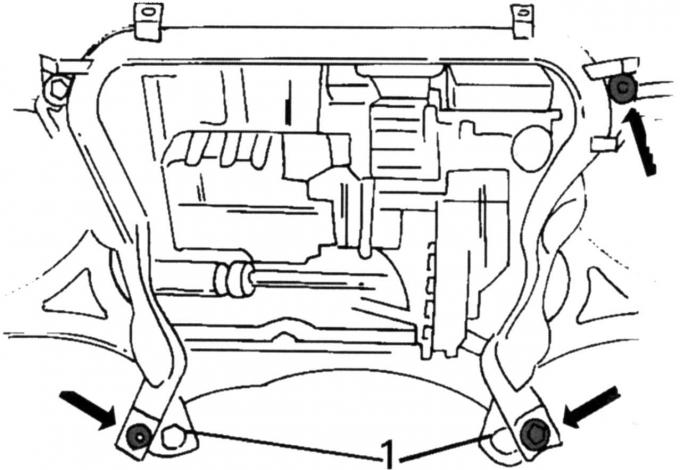

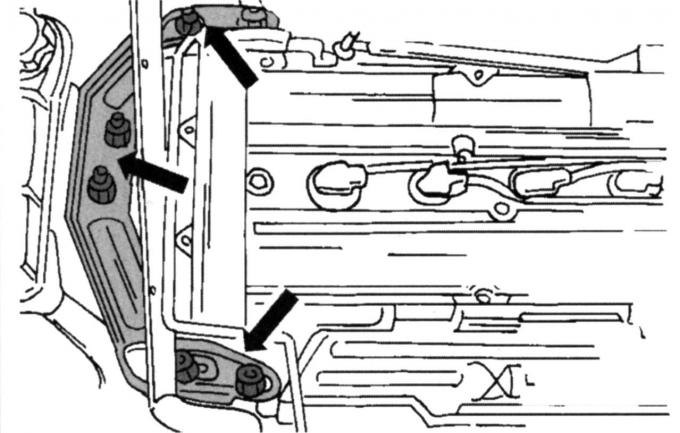

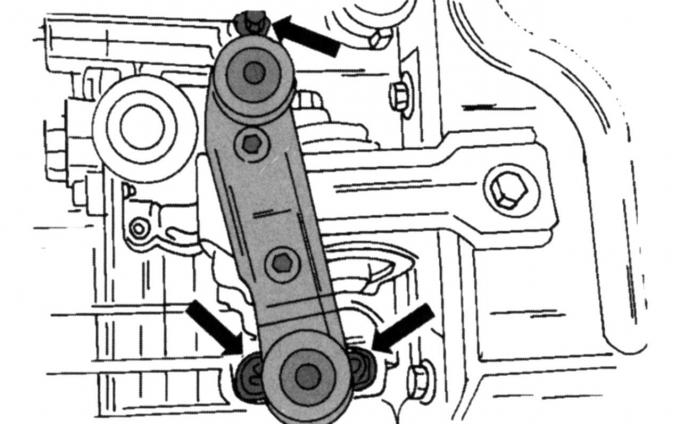

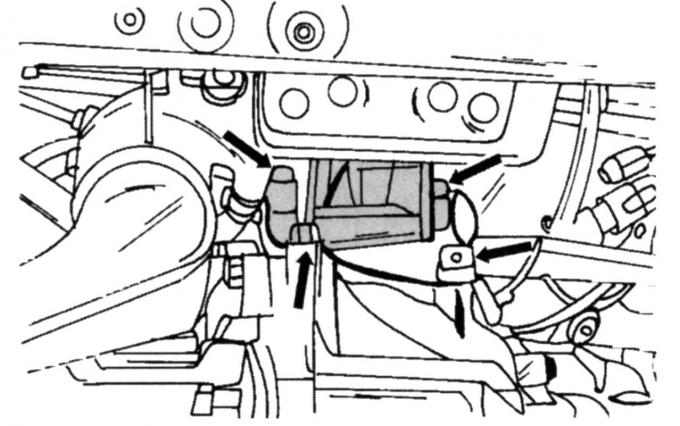

Pic. 37. Location of screws (indicated by arrows) subframe: 1 - guide pins

- unscrew the four screws securing the subframe and lower the subframe (see fig. 37);

- drain the oil from the gearbox;

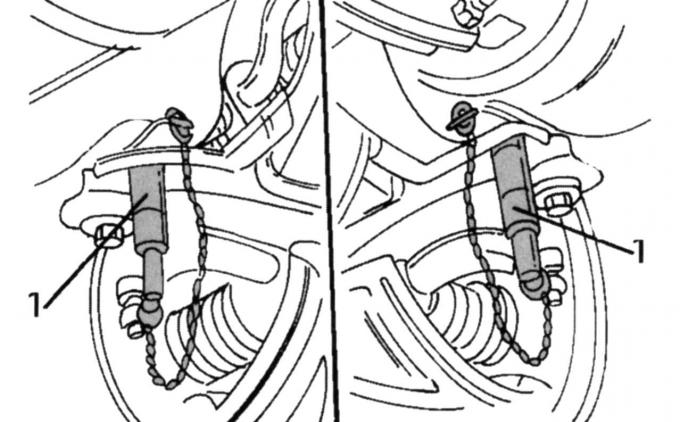

Pic. 157. Removing the right wheel drive shaft (the arrow indicates the direction of removal): 1 - thrust bearing screws; 2 - heat shield

- Remove the right wheel drive shaft. After removing screws 1 (see fig. 157) and unscrewing the heat shield 2, you can remove the shaft from the gearbox (see below). Tie the shaft with a wire to the suspension without creating a large angle in the CV joint;

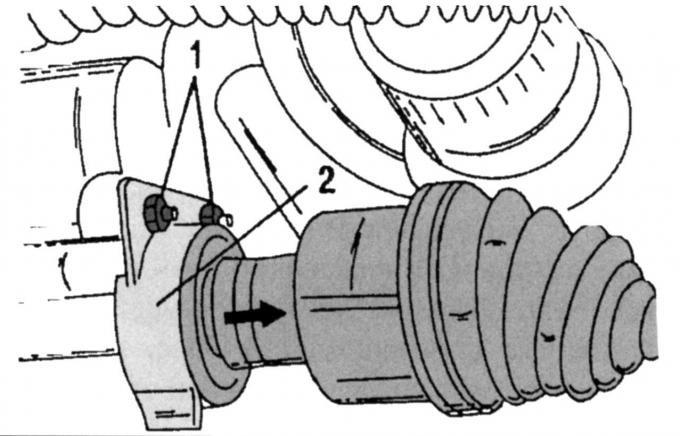

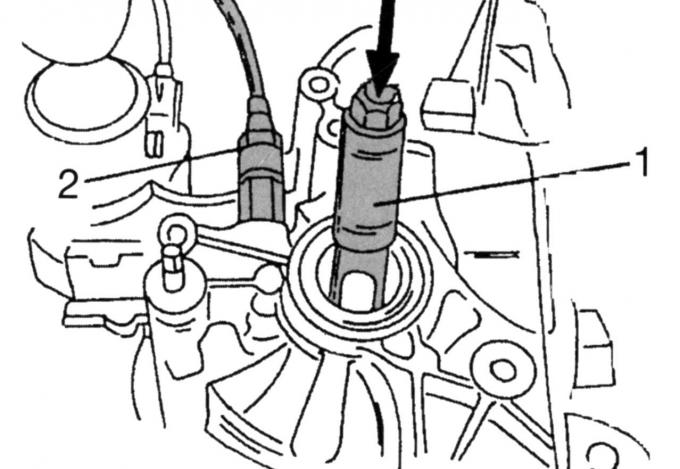

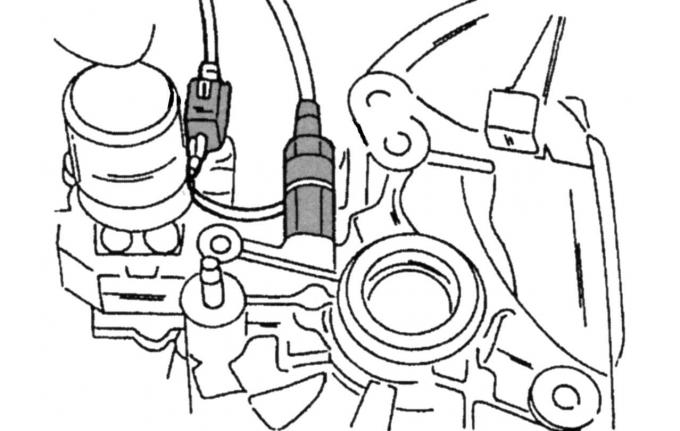

Pic. 158. Removing the left wheel drive shaft: 1 - mandrel; 2 — a nut of fastening of a spiral of a speedometer

- a special mandrel is used to remove the left drive shaft (pic. 158). Use it to knock out the shaft from its seat and remove it from the gearbox. Tie the shaft with a wire to the suspension without creating a large angle in the constant velocity joint. Turn away a nut 2 spirals of a speedometer with an oblique mesh knurling and take a spiral. There is also a speed sensor nearby, which must be disabled;

- install car jack (with wooden spacer between jack head and motor/drive) under the engine/drive and raise the power unit to relieve the engine mount;

Pic. 32. Attachment points of the right engine mount

- Turn away an element of fastening of the right suspension bracket of the engine. On fig. 32 shows how the suspension bracket is fixed;

- unscrew the five self-locking nuts (when installing, replace them with new ones);

- take out the bracket;

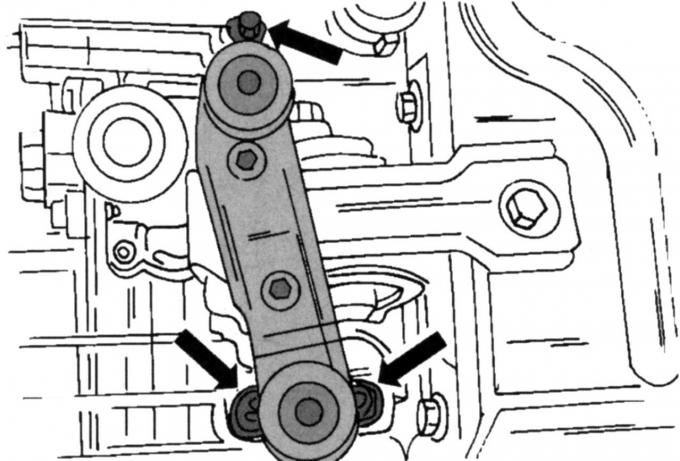

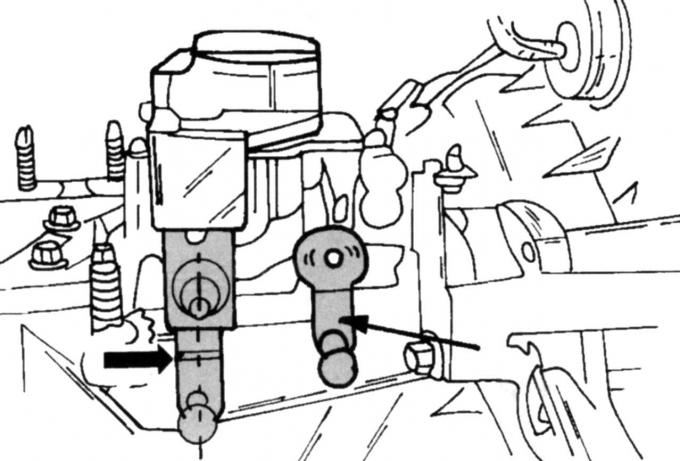

Pic. 33. Attachment points of the left suspension on the drive

- on the opposite side, unscrew the self-locking nuts of the rear engine mount from the gearbox (see fig. 33);

- lower the gearbox so that it is at the same height as the left longitudinal beam;

- Turn out other screws of fastening of a transmission to the engine and other screws of fastening of a starter;

- raise the car;

- Disconnect the low pressure hose of the brake booster on the intake manifold;

- check whether the gearbox is securely supported on the car jack, and carefully remove it. Make sure nothing is connected.

Note: All self-locking nuts, cut cable bundles and other fasteners must be replaced with new ones. When installing the engine, the drive unit must be aligned with the subframe.

Install in reverse order, taking into account the following:

- with an assistant, install the gearbox on the jack and dock on the engine flanges. The clutch release bearing must be strongly pressed towards the inside;

- screw in the screws securing the engine to the gearbox and carefully tighten to 40 Nm;

- tighten the lower starter mounting screws to 48 Nm;

- lower the car;

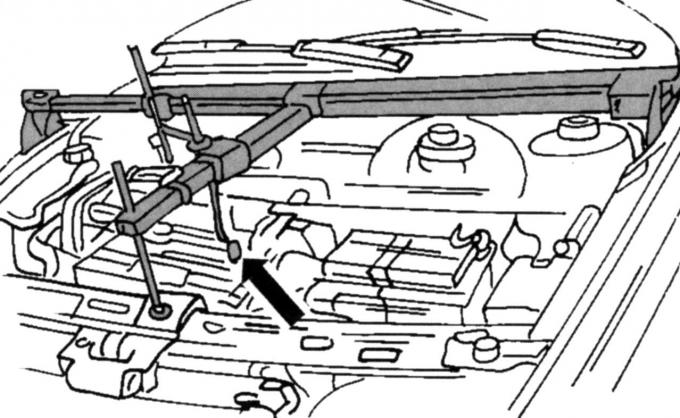

Pic. 34. Device for lifting the engine and drive when hanging the engine

- install a hoist to lift the engine (see fig. 34);

- screw in the fastening elements of the left engine mount (see fig. 33) on the gearbox without tightening them;

- screw fastening elements of the right engine mount (see fig. 32) on the gearbox without tightening them;

- Install the left drive shaft;

- install a new circlip in the groove of the shaft before pushing the end of the shaft into the gearbox;

- slide the right drive shaft into the gearbox, install the thrust bearing and tighten both screws 1 (see fig. 157) torque 27 Nm;

- install heat shield 2;

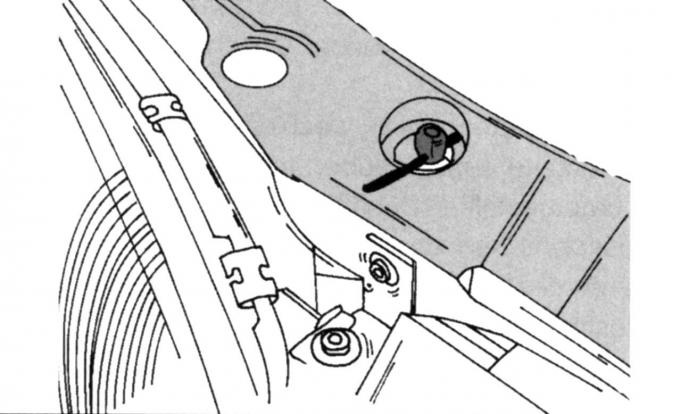

Pic. 159. Location of the elements of the speedometer: 1 - sensor; 2 - spiral

- screw in the speed sensor and speedometer coil (pic. 159);

- install the subframe;

- Install the front suspension;

- tighten the terminal «masses» between the gearbox and the body torque 47 Nm;

- Install the details of the exhaust system on the rubber rings and tighten the connection with the exhaust manifold to 40 Nm;

- install the wheels;

- lower the car;

- Tighten the wheel nuts.

To remove the transmission from a vehicle equipped with a V6 engine, proceed as follows:

- Disconnect the storage battery and remove it;

- Set the gearshift lever to neutral position;

- remove the rubber casing upwards;

- disconnect both ventilation hoses from the side of the air intake hose;

- loosen the hose clamp on the throttle body;

- disconnect the low pressure hose on the rear side;

- unplug the air meter at the front;

- release the air filter from the rubber suspension and remove it;

- Drain the brake fluid from the reservoir;

- loosen the nuts in the center of both shock absorber struts of the chassis on both sides by five turns;

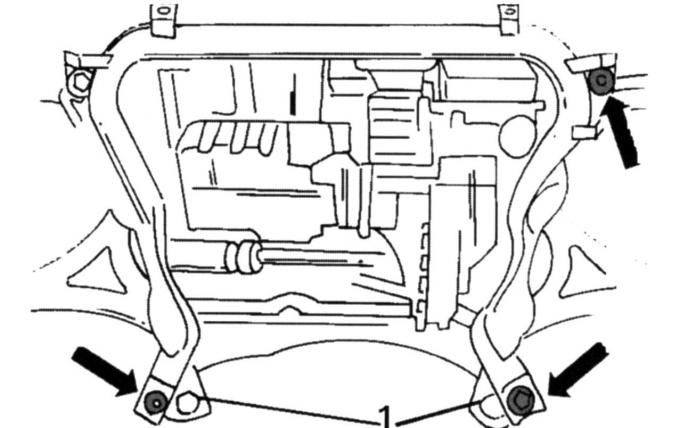

Pic. 161. Radiator mount

- fix the radiator (pic. 161);

- Release the water pump hose from the spring clip;

- unscrew three screws and remove the cover;

- Remove the casing of the water pump;

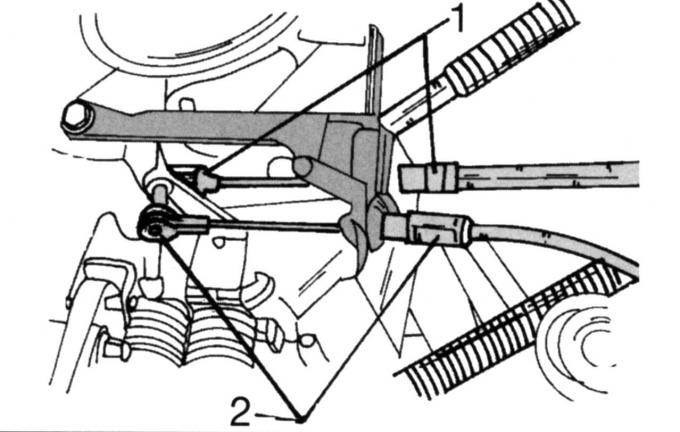

Pic. 162. Mounting cables: 1 - cable speed control rod; 2 - throttle control cable

- unhook the traction on the cables (pic. 162);

- unscrew the cable fastener «masses» and move the cable aside;

- Take out two plugs of wires on a transmission. At the same time, pull one off and disconnect the other (speed sensor and reverse warning lamps);

- Turn out both top screws of fastening of a transmission to the engine;

- raise the power unit (see fig. 34);

- Disconnect the hydraulic clutch;

- collect the fluid flowing from the hydraulic drive;

Pic. 163. Mounting points of the left engine mount on the gearbox

- Disconnect the left transmission suspension from the transmission (pic. 163);

- Establish a forward part of the car on support and merge transmission oil;

- clean the cork and tighten it (45 Nm);

- Disconnect the catalytic converter in front and behind from the flange connections and remove it;

- from the inside turn away and remove facing of both wheel niches;

- Disconnect the system of rods and levers of the anti-roll bar from the shock absorber strut of the chassis;

- Disconnect the ball joint to the left and to the right of the lower surface of the steering knuckle;

- Remove the cover under the radiator;

- unscrew the shock absorber support from the subframe;

- Disconnect the oil pipe clamp on the subframe;

- unscrew the screws on the underside;

- Turn out the average screw;

Pic. 164. Fastening the left stop of the engine (V6 engine)

- unscrew the supporting console of the stop (pic. 164);

- Turn out the average screw on the right stop from turning;

- turn away three screws and remove an emphasis;

- unscrew the carrier console (see fig. 156);

- unscrew the subframe screws (see fig. 37) and lower it in the back;

- Remove a heat-shielding guard of a steering;

- unscrew the shift cable and the selection cable from the gearbox and remove it together with the bracket;

- unscrew the steering from the subframe (two screws on each side);

- put the car jack under the subframe (see fig. 37) and completely unscrew the screws securing the subframe;

- lower the subframe;

- Remove the wheel drive shaft on the right. Fix the shaft with a wire on the suspension, without creating a large angle in the constant velocity joint;

- remove the drive shaft on the left using a special mandrel (see fig. 158). Fix the shaft to the suspension without creating a large angle in the constant velocity joint;

- unscrew nut 2 with an oblique mesh knurling and remove the speedometer coil;

- put the car jack under the engine/drive (with wooden spacer between jack head and motor/drive) and raise the power unit;

- Turn out the bottom screws of fastening of a transmission to the engine: three - on the back side, three - in a forward part;

- remove the starter;

- Remove other knots established on a transmission;

- Lower the gearbox so that it can be taken out.

Install in reverse order, taking into account the following:

- align the drive unit with the subframe;

- install the gearbox on a car jack and dock the engine flanges;

- screw in the screws securing the gearbox to the engine and tighten them to a torque of 40 Nm;

- install the starter and tighten the screws to 25 Nm;

Pic. 165. The position of the gear levers

- install the gearbox in «neutral». Both levers (pic. 165) must be in the position shown in the figure;

- Establish an arm of fastening of a cable of switching, tighten nuts and attach both cables of switching;

- connect shift cables with levers and put on clip-on clips;

- set the steering in the correct position, insert the screws and tighten the screw on the left and right with a torque of 130 Nm;

- Install the heat shield and oil pipe clamp;

Pic. 166. Arrangement of guide pins (15-097)

- install the subframe. Insert both guide pins (pic. 166) and align the subframe so that the guide pins are in the middle of the holes on the body;

Pic. 167. Location of guide pins

- Establish a steering, as it is shown in fig. 167;

- tighten the screws shown by the arrows to a torque of 130 Nm;

- Take out both directing pins 1;

- install the lifting device;

- fix the ropes in the lifting eyes;

- Establish an arm of the right emphasis from turning;

- tighten the screws to 85 Nm;

- set the stop;

- tighten the three screws to 48 Nm;

- tighten the middle screw with a torque of 120 Nm (after installing the left-hand anti-rotation stop);

- install the subframe;

- tighten the subframe fastening screws to 130 Nm;

- establish the console of the left emphasis from turning;

- tighten the screws to 48 Nm;

- insert the middle screw and tighten it with a torque of 30 Nm;

- install the catalytic converter with a new seal and tighten the screws in the flange connection to 40 Nm;

- Establish a protective cover under a radiator;

- Establish the left drive shaft in a transmission. Install a new circlip into the groove of the shaft before installing the end of the shaft into the gearbox;

- Install the right drive shaft in the gearbox;

- screw on the thrust bearing and tighten both screws 1 (see fig. 157) torque 27 Nm;

- attach the speed sensor and the speedometer coil (see fig. 159);

- Install the front suspension;

- tighten the upper screws securing the gearbox to the engine to 40 Nm;

- carry out further installation in the reverse order of removal;

- bleed the air from the hydraulic drive of the brake system.

Visitor comments