- When loosening nuts on studs, always clean the protruding threads with a wire brush to remove dirt or rust. This prevents the nut from being screwed onto a contaminated thread. Then treat the joint with a rust remover spray;

- if you need to remove the screw screwed into the welded nut (mostly on the body), if possible, treat the threads on the reverse side with a rust remover spray. The bolt heads of such connections often come off, and sometimes the welded nut is also torn off;

- sometimes it is very difficult to turn off the screws with slotted or cross heads. Phillips screwdrivers often slip out of the slot and damage it in the process. In such cases, you can install a screwdriver in the slot with a hollow shaft and apply a short blow with a hammer. In most cases, the head of the bolt separates from the connection, and the screw is easy to turn out;

Pic. 9. Graduated disk (A) and screws «Torx» (IN)

- in modern automotive industry, screws with special heads are used more and more, which look like cross-heads, but they are not. Screws with such heads, called «Torx» - heads, turn out with special inserts, which can be purchased in a set. On fig. 9 shows such a screw. For insert bowl type «Torx» the sliding ratchet, extended handle, etc. can then be installed in the usual way;

- hexagon socket screws (hex head) or cap screws «Polygon» (multiple engagement, mainly 12 corners) may also create difficulty in turning away. Clean the hexagon hole properly first (e.g. with a small screwdriver), to properly install the Allen key or Allen wrench. If possible, also use a nozzle. Before loosening the screws, you can apply a short hammer blow to the nozzle to loosen the resistance of the screw. However, an angled hex is sometimes required, but due to its angled position, loosening is sometimes difficult. In this case, proceed as follows: insert the key into the screw and put a small ring wrench on the long end of the hexagon. Now hold the hex wrench well and loosen the screw while applying pressure to the ring wrench. In this way, internal turning of the angle key in firmly seated screws is avoided;

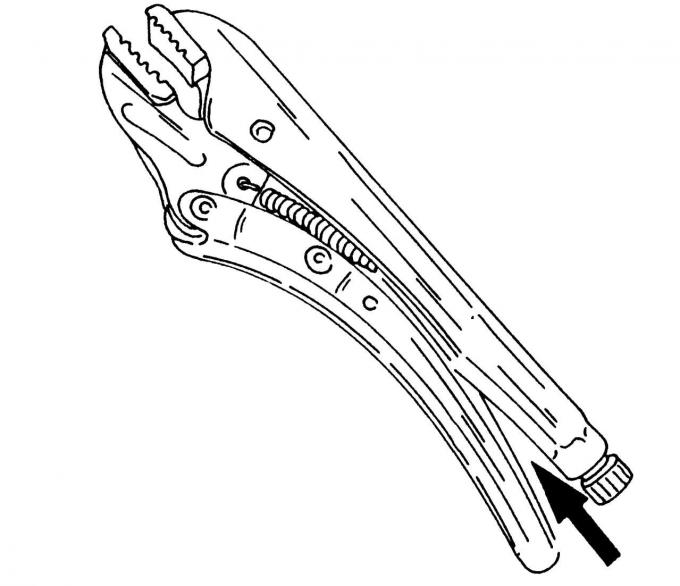

Pic. 15. Clamp

- in easily accessible places, small heads of Allen screws can be gripped with a clamp (pic. 15) and thus unscrew the screw, especially if the internal hexagon already has rounded edges.

Do not injure your fingers when squeezing the clamp;

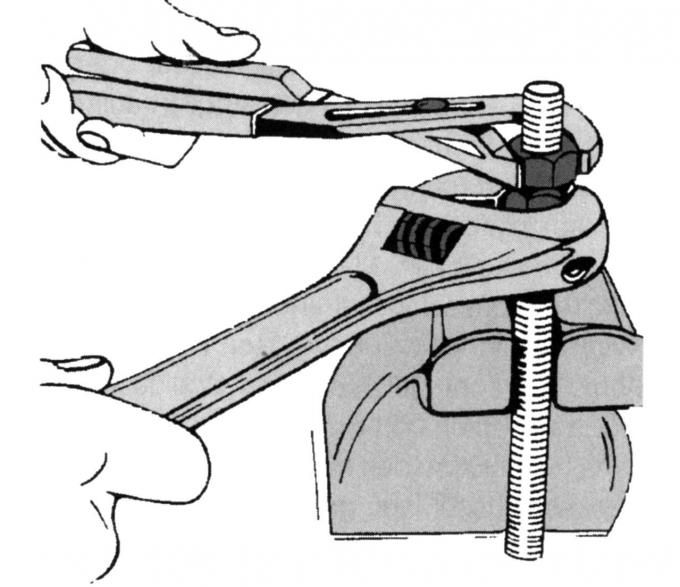

Pic. 16. Using a nut splitter

- sometimes difficulties may arise when loosening nuts or screws, the edges of which are rounded during operation, with a wrench of the wrong size (sometimes happens on used cars). You can try to unscrew the nut or screw with the clamp mentioned above. Depending on the position of the nut, it can also be cut off with a chisel or sawn along the thread. If you have a spacious working room, you can use a nut splitter. The tool works as shown in fig. 16, i.e. the screw is tightened until the nut snaps. The advantage is that the thread of the screw is not damaged when using such a tool;

- self-locking nuts are often mentioned in the text. They always need to be replaced with new ones;

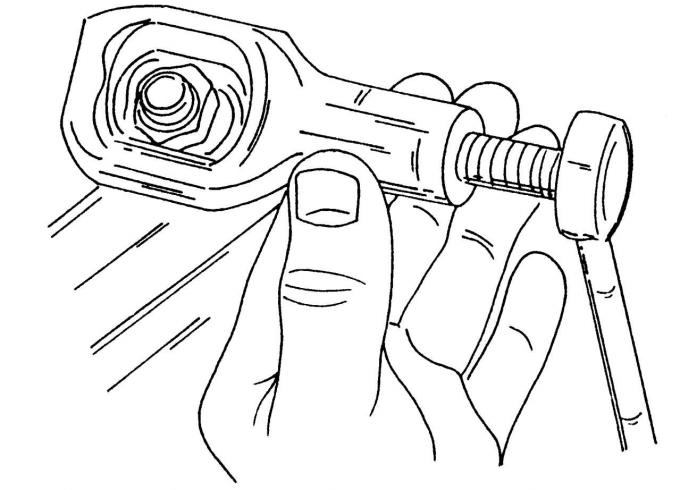

Pic. 17. Pullers with left-hand thread

- sometimes it happens that the head of the screw breaks off. To remove the remaining threaded part from the hole, drill a hole in the middle of the screw and use a so-called left-hand thread puller (pic. 17). It can be purchased at auto parts stores. The puller is screwed into a drilled hole like a screw. When tightened, the tool cuts into the rest of the screw and makes it possible to pull it out. Another solution is to ream the screw thread to approximately the diameter (somewhat less) and subsequent threading with a tap;

Pic. 18. Installing and removing studs

- the spacer bolts are unscrewed with the help of two nuts locking each other. Install the wrench on the inner nut when turning out, and on the outer nut when screwing in. On fig. 18 shows how to unscrew and screw in the bolts;

- sometimes, when tightening screws, the threads cut in aluminum parts are damaged. It can be restored with Heli-Coil threaded inserts.

Tightening torques

In this manual, the tightening torques of the screws and nuts of the main critical connections are indicated. Appropriately sized socket inserts and a torque wrench, sometimes with an extended handle, must be used to meet the required tightening torques.

It is often not possible to reach the screw or nut to install the torque wrench, or the tightening torque is too low to fix on the torque wrench. Here you just need to estimate the tightening torque. It means in the language of mechanics «well tighten», and the sense of proportion plays an important role, especially with a thread diameter of 6 or 7 mm.

Visitor comments