Steering gear

Have an assistant turn the steering wheel from lock to lock. Check the turning mechanism for smooth rotation and make sure that no parts of the mechanism, including wheels or tires, touch the brake hoses or any parts of the body.

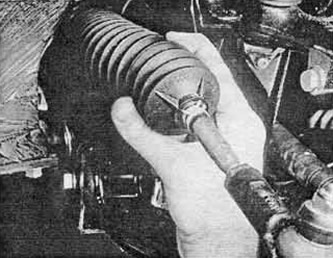

Check that the rubber protective covers are not damaged and that the clamps are securely fastened. If equipped with power steering, check for damage or leaks from hoses, pipes or connections. Check for excessively tight or sticky steering, loose cotter pin or other fasteners, or severe body corrosion within 30 cm of any steering component attachment point.

Front and rear suspension and wheel bearings

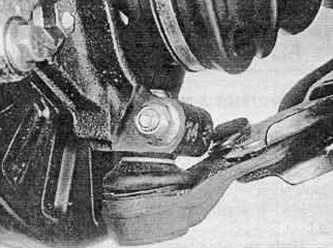

Starting with the front right wheel, grab it at the 3 and 9 o'clock positions and push it vigorously. Check for play or looseness in the wheel bearings, ball joints, bearings, pins, or suspension pivots.

Now grab the wheel at the 12 and 6 o'clock positions and repeat the previous check. Rotate the wheel and check the ease and uniformity of the course of its bearings.

If you suspect play in any connection, you can check this by pressing with a power screwdriver (or something similar) between this connection and its support. In this case, it will become clear where the wear has occurred: in the connection sleeve, fastening bolts or in the support (bolt holes are often lengthened).

Perform the entire set of checks on the other front wheel and then on both rear wheels.

Springs and shock absorbers

Check suspension struts for significant leaks, corrosion, or shroud damage. Check the security of all attachment points.

In the presence of cylindrical springs, check the position of the extreme coils of the suspension springs in their supports, as well as the absence of cracks, breakage and corrosion of the springs.

If leaf springs are present, check that the leaf springs are undamaged, that the springs are securely attached to the axle mounts, and that the mount eyes, bushings, and spring clevises are undamaged.

The same general testing principles apply to vehicles with a different type of suspension, (torsion, hydraulic, etc.). Check that all fasteners are secure, that there are no signs of excessive wear, corrosion, or damage, and that there are no leaks in the hydraulic type hangers and that the pipes and their connections are not damaged.

Inspect the shock absorbers and make sure there are no major leaks. Check the bushings and fasteners for wear and make sure that the housings are not damaged.

Drive shafts (only for front wheel drive vehicles)

Rotate each front wheel in turn and inspect the CV joint guards. Also check that the drive shafts are not bent or damaged.

Brake system

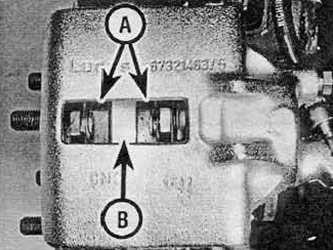

If it is possible to do this without dismantling, check the wear of the brake linings and the condition of the discs. Check for excessive friction lining wear (A) and in that. what drives (IN) no cracks, chips, pitting or excessive wear.

Check the condition of all metal brake pipes under the vehicle and the condition of the flexible hoses. Look for corrosion, fraying, or loose tubing, as well as bulging, fraying, or corroding of flexible hoses.

Look for signs of brake fluid leakage on the caliper and back wall of the brake. Repair or replace worn parts.

Slowly rotate each wheel while your assistant depresses and releases the brake pedal. Make sure each brake stops the wheel and does not rub when the pedal is released.

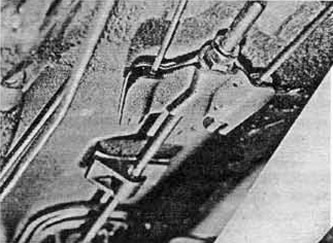

Check the handbrake actuator for frayed or broken cables, excessive corrosion, wear and loose fittings. Check the braking of each wheel and make sure that when the brake is released, the wheel rotates freely without binding.

The effectiveness of the brakes cannot be tested without special equipment, but the brakes can be tested on the road later. At the same time, it is necessary to check whether the car is skidding when braking.

Fuel system and exhaust system

Inspect the fuel tank (including lid), fuel lines, hoses and connections (fittings). All components must be in good condition and show no signs of leakage.

Examine the entire length of the exhaust system for damage, broken or deformed parts, rust or corrosion.

Wheels and tires

Inspect the sidewalls and tread area of each tire. Check for breaks, bulges, tread breaks and cord damage.

Check that the tire nipple is correctly positioned on the inner side surface of the wheel rim. Check that the nipple is intact and the wheel rim is not damaged or deformed.

Make sure the tires are the correct size for the vehicle, that each axle has the same type and size of tires, and that the tire pressures are correct.

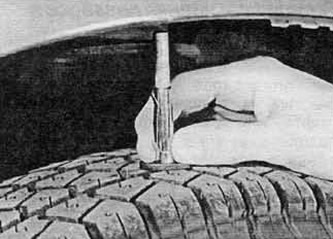

Check the tire tread depth. A minimum depth of 1.6mm must be present in a zone that is at least 3/4 of the tread wide. Abnormal tread wear may indicate incorrect front wheel alignment.

Body corrosion

Check the condition of the car body and check for signs of corrosion, especially in stress-bearing areas (spars and box-shaped chassis parts, sills, cross members, struts and the entire suspension, steering, brake system, safety belt mounts, etc.). Any corrosion that severely reduces the thickness of the metal in the stressed area can cause an accident. In such cases, it is necessary to repair the body by contacting the services of professionals.

Damage or corrosion that results in sharp edges on the bodywork may be grounds for declaring the vehicle unserviceable.

Visitor comments