Attention! It is recommended that you first practice applying varnish, for example, on an old wing.

The surface to be varnished must be dry and dust-free. If possible, blow it with compressed air.

Moisten the floor with water to prevent dust formation.

Wipe the repair site and surrounding area with the silicone remover. An even more optimal base for a topcoat will be created by wiping with a polishing caste that removes silicone.

Shake the aerosol can vigorously for at least 3-5 minutes before use, otherwise the varnish will streak on the surface.

For Metallic Varnish, apply a small amount of spray paint to some cardboard to remove any metal particles deposited on the riser tube.

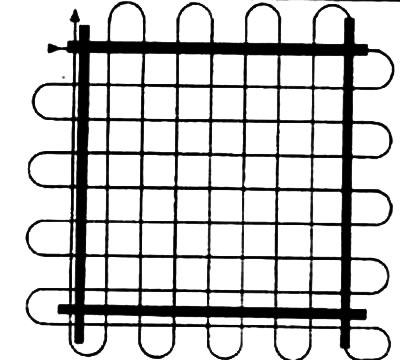

Large vertical and horizontal surfaces are sprayed crosswise": start spraying outside the surface and continue to move the jet in the other direction, also starting from the outside.

Small surfaces are sprayed in a spiral from outside to inside to avoid overspray.

Guide the aerosol can at a uniform speed and at the same distance (approx.25 cm) from the surface.

To ensure a transition to a healthy varnish as imperceptibly as possible, it must be applied in at least four overlapping spray strokes. Each individual application should increase the surface of the previous applied layer by two to three centimeters.

Attention! If spraying is carried out at too close a distance, the spraying movement is too slow or occurs at a variable speed, so-called varnish runs occur. This means that in some places the varnish flows down, because. too much of it is sprayed in the same place. The same happens if, when changing direction during spraying, the sprayer does not pass through a closed surface.

Repeat the spraying process with 5 minute pauses to evaporate the solvent until there is sufficient varnish coverage. Shake the spray can between individual spraying strokes, especially for Metallica, as Metallic particles settle quickly.

Attention! It is very difficult for Metallic lacquer to achieve a color match with a branded lacquer. Pigmentation (aluminum particle distribution) will be more uniform. if the last spraying process is carried out from a distance of 30 cm rather than 25 cm.

Metallic lacquer coating is provided with Metallic base lacquer with a transparent coating (transparent) lacquer, only after that Metallic lacquer acquires its shine. Spraying occurs 3-4 times, with a pause of several minutes each time. Before the first application, the base varnish must be left open for at least 30 minutes. The transparent lacquer should cover the new base lacquer by approximately the width of the hand, before that the protective paper should be expanded accordingly.

Empty the aerosol can. To do this, install the spray can on the head and spray the paint until it is gone.

Remove all protective coatings immediately after finishing painting work.

Let the varnished surface dry. Drying can be accelerated with a strong photo or reflector lamp.

Attention! Do not use a fan as as a result, swirling dust particles can be deposited on the fresh varnish.

After the paint has hardened, after at least 48 hours, carefully remove the sprayed mist on adjacent surfaces with a soft polish and a cotton swab. Polish only in the longitudinal direction of the vehicle.

Visitor comments