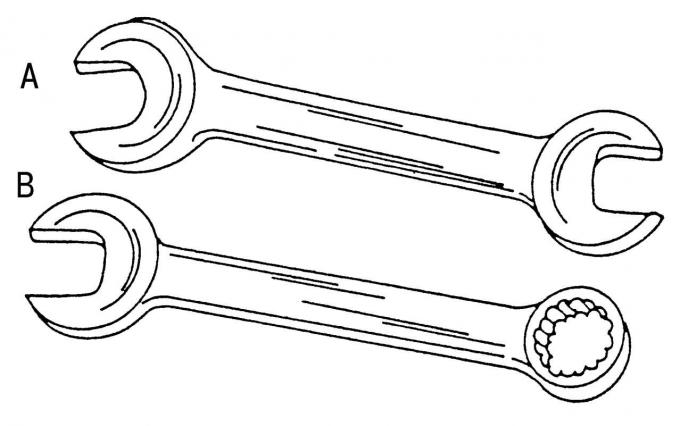

Pic. 8. Double ended wrench (A) and ring wrench (IN)

For repairs, you need the most complete set of high-quality tools. A good tool can be used for a long time, it will always justify the cost of acquiring it. The basis of the tool kit is a set of open end wrenches that can be used on any easily accessible part of the car. A set of open end wrenches is desirable and can be used on tight screws and nuts or in tight spaces. To keep costs down, you can get by with a set of combination wrenches that have an open end on one end and a ring of the same size on the other. On fig. 8 shows such keys. It is advisable to purchase cap heads (inserts). If the outer diameter of the sockets is not too large, they can also be used to unscrew nuts and screws in hard-to-reach places or recesses. In addition, you will need a set of Phillips screwdrivers, pliers and a hammer.

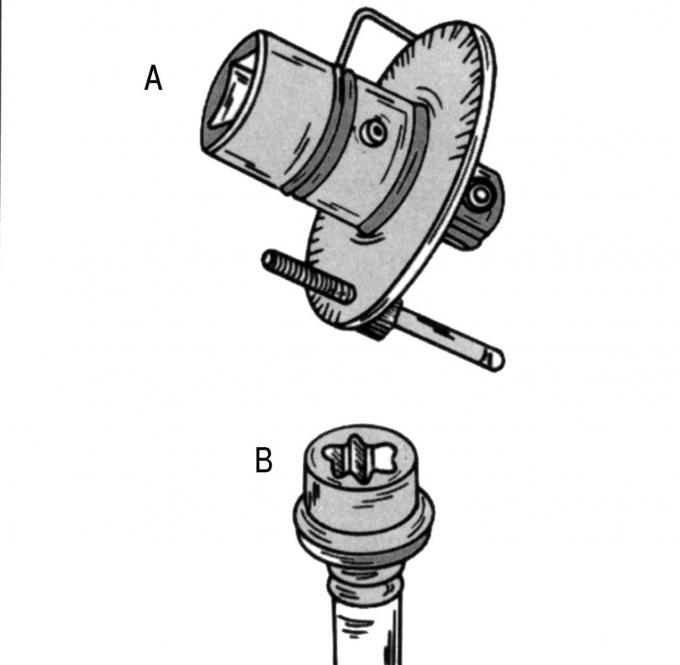

Pic. 9. Graduated disk (A) and screws «Torx» (IN)

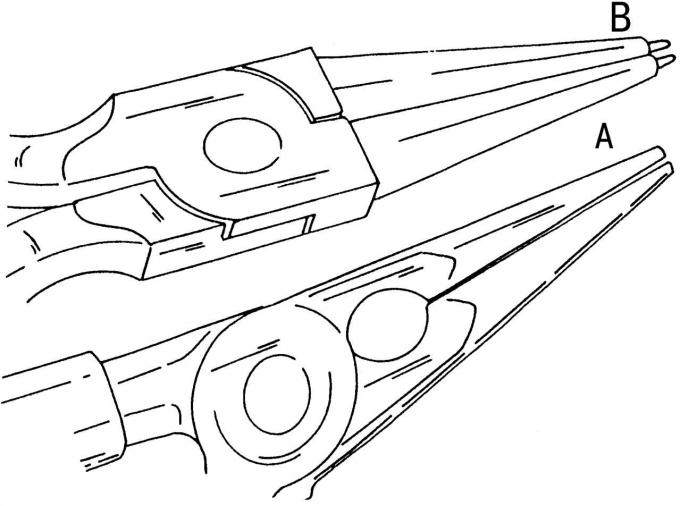

Pic. 10. Round nose pliers (A) and needle nose pliers (IN)

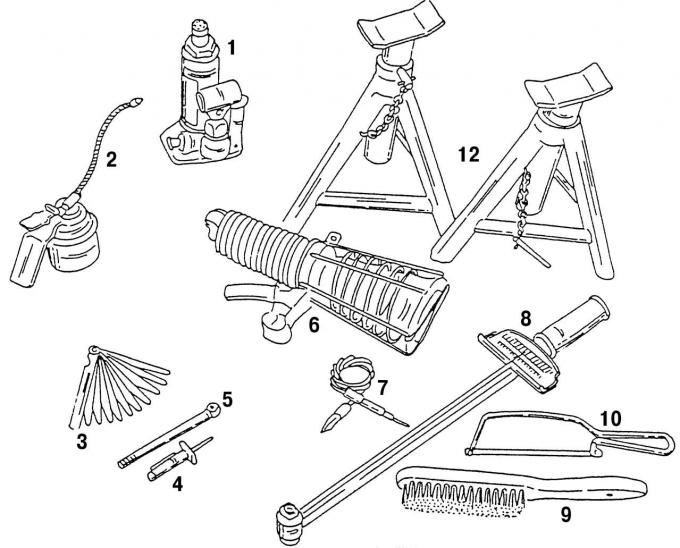

Pic. 11. Tools and aids for car care and repair: 1 - hydraulic jack; 2 - oiler; 3 - probes for checking clearances; 4 - tire profile gauge; 5 - pressure gauge for tires; 6 - electric portable lamp; 7 - control lamp (12 V); 8 - torque wrench; 9 - wire brush; 10 - hacksaw; 11 - coupler of piston rings; 12 - tripod supports

In the automotive industry, so-called screws are increasingly used «Torx» (pic. 9). To loosen these screws, a special socket set is used. In addition to the basic equipment, you can purchase an impact screwdriver, without which it is hardly possible to unscrew the machine-tightened Phillips screws without damaging them. Of course, it can also be used to tighten the connections, to ensure the tightness of the connections. Circlip pliers are also often required, as transmission gears, shafts and similar parts are held in most cases by circlips that are very difficult to remove with a screwdriver. On fig. 10 shows two types of pliers, for external circlips, which can be opened with pliers, and for internal circlips. They come with straight or beveled teeth. Useful thing - torque wrench (pic. eleven). If the required tightening torque of the screw or nut has already been reached, it will slip. They also produce keys with an indicator that shows the torque reached. In this connection, the graduated disk should also be mentioned. It looks like shown at the top of Fig. 9. Many screws and nuts have to be tightened to a certain angle (corner tightening). To do this, it is best to use a graduated disk.

The more complex the design of the car, the more devices and tools are required for its self-service. Some types of work cannot be performed without special, usually expensive, fixtures and tools.

On fig. 11 shows the most commonly used tools and aids. We advise you to purchase them if you intend to service the car yourself.

When working on a vehicle, observe the following safety precautions to protect yourself from possible injury:

- Do not work under a car that has been raised by a car jack. Always substitute additional supports. If they are not there, you can put, for example, two wheels on top of each other;

- never tighten the wheels or wheel hub nuts if the vehicle is on jack stands;

- never unscrew the cap of the expansion tank of the cooling system on a hot engine. If this is unavoidable, wrap a thick rag around the lid and turn it up to the first latch so the steam can escape;

- never drain the engine oil immediately after the end of a trip. Dispose of engine oil in specially designated areas and only in accordance with current regulations;

- Do not allow brake and coolant to get on the car's paintwork. The resulting stains are difficult or impossible to remove;

- Do not inhale brake dust. Although brake linings and pads are made without the use of asbestos, the dust from abrasion is harmful to health. If you blow out the brakes with compressed air, turn away, try not to breathe in the dust. Inquire about the possibility of purchasing aerosols that are used to treat brake parts to avoid dust formation;

- immediately wipe off the remains of oil or grease from the floor - it is easy to slip on a slippery floor;

- do not use wrenches of the wrong size or bored wrenches to loosen nuts or screws. A slipped key can injure. In any case, cover the open wound with a band-aid before dirt and oil can penetrate it;

- you can not repair a car in a tie, in long and fluttering clothes. Tie up long hair while you work. It is better to remove rings and bracelets - they can be caught on something, moreover, they conduct current well;

- free the workplace from foreign objects so as not to trip over them;

- It is better to work with an assistant. Family, friends or acquaintances should sometimes check if everything is in order;

- never try to complete the work in a hurry - many nuts will remain loose;

- in accordance with fire safety regulations, never smoke in the immediate vicinity of the car and do not allow others to smoke. Remove the terminals from the battery if the fuel lines are blocked. Short circuits caused by metal objects can cause sparks. For everyone «firefighter» keep a fire extinguisher ready;

- never place a portable lamp on the engine. Some portable lamps generate a lot of heat and can cause a fire even though they are protected by a wire grill. It is best to hang it in the engine compartment to the open hood when working.

Warning: The use of poor quality tools in most cases leads to injury and damage to fasteners, etc. High quality tools are a good start to self-service car.

The following tools and aids will greatly facilitate the repair and improve its quality:

- range of screwdrivers with anti-slip handle for slotted, cross-head and «Torx» - head;

- a key for spark plugs SW 16, a special socket wrench with a rubber insert;

- keys with an internal hexagon on a ring with dimensions of 2–8 mm. The edges of these keys wear out quickly. If the key slips off several times to no avail, purchase a new set;

- With the help of a cross wheel wrench for passenger cars, you will also unscrew the firmly seated wheel screws. In other cases, the wheel wrench from the driver's tool kit should be enough;

- pliers, tongs for the water pump (length not less than 240 mm) and side cutters bend, hold, turn and separate almost all materials on the car;

- locksmith's hammer (recommended weight approximately 300 g) used to, for example, knock out a firmly stuck bolt from the connection with a punch. «sensitive» Structural elements such as bearings, cast or hardened parts, on the other hand, should only be machined with a plastic or rubber mallet. A straightening hammer will help with body work;

- center punch is used for drilling operations on metal. Place the hardened point exactly where you want to drill. With a light blow of a hammer on the center punch rod, a small depression is made on the surface, into which a drill bit for metal is installed;

- punch (diameter 3 and 6 mm) universal for assembly and disassembly work with the chassis, engine and brakes. If you remove stop bolts with it, pay attention to the fact that the contact surface of the punch approximately corresponds to the size of the bolt, otherwise it will deform.

Warning: Repeated use of the punch will result in fringe-like burrs from hammer blows. It may happen that a piece of flattened material suddenly breaks off and bounces into the eye. Therefore, only work with punches that are free of burrs on the impact side. You can try to slightly grind such a punch so that it looks like «safe».

- with a chisel (hardened blade) if necessary, you can also deal with deformed or rusted threaded connections by chopping off the nut along with a piece of the threaded bolt. However, on «soft» places your assistant should support the hammer below at the point of impact so that there is no deformation;

- for work in the engine compartment and under the car, it is recommended to purchase a set of socket wrenches with 10–32 mm inserts and a ratchet wrench. The kit is cheaper than buying the necessary inserts separately. This also includes the kits already mentioned «Torx» - inserts;

- for work in the cabin, a set of socket wrenches will be useful. Along with Phillips screws, slotted screws, type screws «Torx» and plastic clip manufacturers use screws from SW6 to 13 mm;

- for working with electronic systems, the following are recommended: pliers and a screwdriver with handles made of insulating material, pressing pliers, plug-in and wire connectors, a phase test lamp with a needle and a separate cable for connection to «mass».

Note: Check the driver's tool kit. You should have everything you need in case of a breakdown on the road. Does the kit include a car jack, wheel cross and a screwdriver? In case of loose contact or a weak connection of wires, electrician's pliers, several wires and electrical tape will help. You must also have a set of lamps and replacement fuses, a tow rope, a wire for connecting to an auxiliary battery, and a flashlight. And do not forget that during unforeseen repairs on the road, your hands become dirty. Bring paper towels or handkerchiefs with you (they are also necessary when monitoring the level of oil in the engine, fluid in the power steering reservoir, etc.).

Visitor comments