Withdrawal

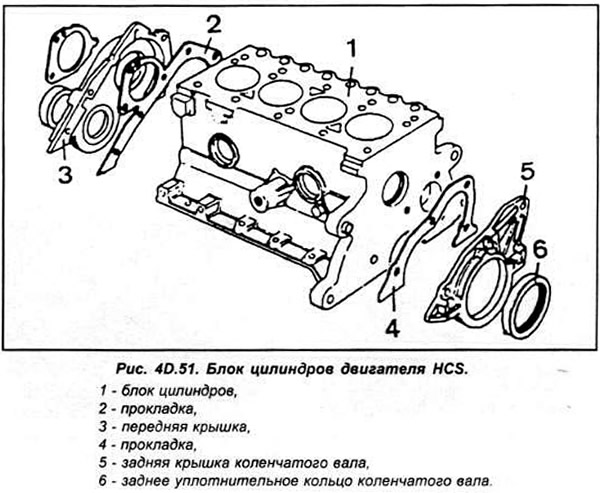

HCS and Endura-E engines

Remove the cylinder head and oil pan. Remove the oil pickup pipe and strainer.

Temporarily install the crankshaft pulley as follows. so that the crankshaft can rotate. Check for markings on the lower connecting rod cap and connecting rod. If there is no marking, it must be applied in order to install the pistons with connecting rods in their places and in the correct position.

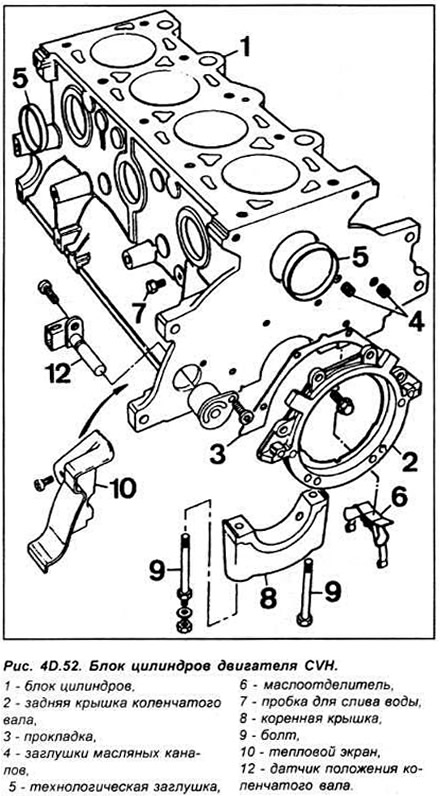

CVH and PTE engines

Remove the cylinder head, oil pan, oil pickup pipe and strainer. Temporarily install the crankshaft pulley so that the crankshaft can be rotated. Check identification numbers. which must be marked on the lower ends of the connecting rod on the exhaust manifold side.

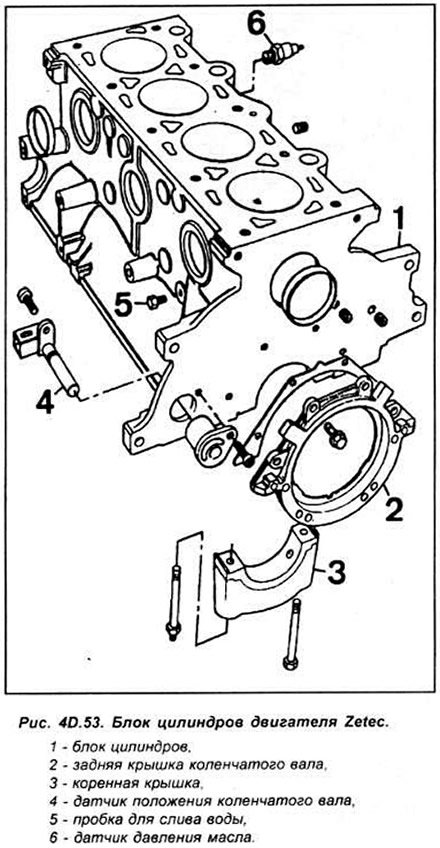

Zetec and Zetec-E engines

Remove the cylinder head and oil pan. Unscrew the screws securing the oil pickup pipe with the strainer to the oil pump, then unscrew the 4 nuts and remove the oil screen (see fig. 40.49).

Temporarily install the crankshaft pulley so that it can be rotated.

Check that the connecting rods and the bottom cover of the connecting rod have identification numbers. The numbers are visible from the exhaust manifold side of the engine. In addition, each piston has an arrow pointing towards the timing belt. If there are no identification marks, apply them (see fig. 4D.50).

All engines

Using your finger, check if there is a pi at the top of the cylinder (step).

Gradually unscrewing the connecting rod bottom cap bolts half a turn each time, unscrew the bolts. Remove the lower connecting rod cover.

Using a wooden hammer handle, push the piston and connecting rod out of the cylinder.

Repeat the operation to remove the pistons with connecting rods on the remaining cylinders.

After removing the pistons with connecting rods, reinstall the connecting rod caps on them.

Examination

Thoroughly clean pistons with connecting rods.

Remove the piston rings from the pistons by carefully sliding them towards the top of the piston. not to scratch the aluminum alloy. Never move them towards the piston skirt. Piston rings are easily damaged if removed carelessly. Therefore, this operation must be performed with extreme caution. You can use old probes. Lift one of the edges of the piston ring to be removed from the groove and insert a feeler gauge under it. Slowly draw the feeler gauge around the piston and when the ring is out of its groove, remove it upwards, the feeler gauge will keep it from slipping into an empty groove, if one is already present (see fig. 4D.54).

Clean all carbon deposits from the top of the piston.

Clean the piston ring grooves in the piston using a piece of old piston ring.

Use a solvent to clean the pistons and connecting rods and wipe them dry.

Carefully inspect each piston for cracks around the skirt and piston pin holes.

If the piston skirt is worn, the engine may have overheated. In this case, it is necessary to check the operation of the cooling and lubrication system. Traces of soot on the side surface of the pistons indicate that a gas breakthrough has occurred. A burnt head in the piston or burnt areas along the edge of the piston head indicate that the combustion of the fuel occurred with detonation or explosion, which was the result of an incorrect ignition angle.

Pitting of the piston indicates that coolant has entered the combustion chamber. The reason for this could be the burnout of the engine gasket.

Check the piston pin clearances and ease of movement by turning the connecting rod and piston in different directions.

Do not attempt to separate the pistons from the connecting rods. This work must be carried out at the service station.

Check the connecting rods for cracks or other damage. On CVH engines in connecting rods, the grease groove at the base of the connecting rod must be clean.

Visitor comments